Anti-seepage regenerating asphalt concrete and preparation process thereof

A technology of recycled asphalt and preparation technology, which is applied in the field of anti-seepage recycled asphalt concrete and its preparation technology, which can solve the problems of poor interface bonding strength and damage to asphalt concrete, and achieve the advantages of waste disposal, prolonging service life, and stable and lasting efficacy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

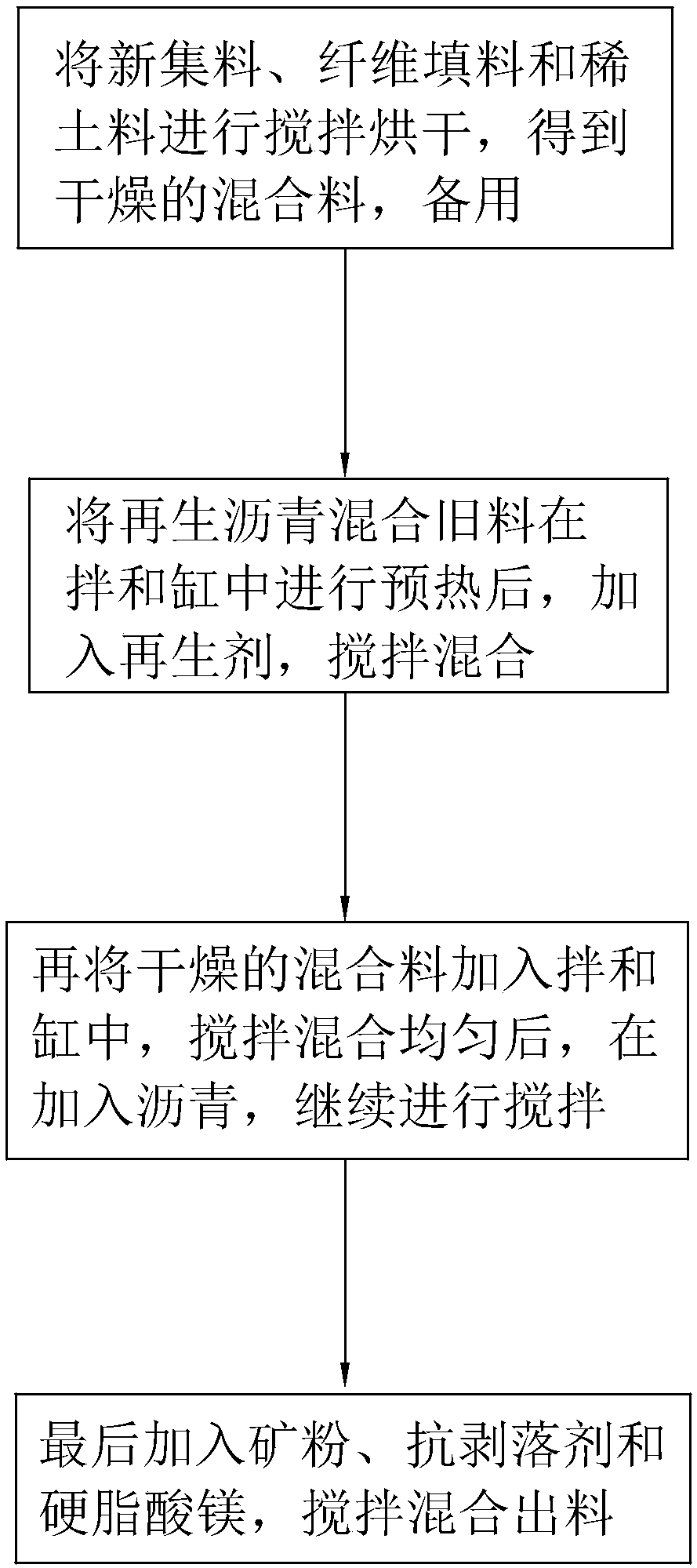

Method used

Image

Examples

Embodiment 1

[0044] Example 1: A kind of anti-seepage recycled asphalt concrete, the components and their corresponding parts by weight are shown in Table 1, and are prepared through the following steps:

[0045] Step 1: Stir and dry new aggregates, fiber fillers and rare earth materials in corresponding parts by weight in a drying barrel. The temperature is controlled at 100°C, the time is 80 minutes, and the stirring speed is 1100rpm to obtain a dry mixture for later use. ;

[0046] Step 2: Put the regenerated asphalt mixed with the old material into the mixing tank, after preheating, add the regenerant, and stir and mix. The temperature in the mixing tank is maintained at 180°C, the stirring speed is 800rpm, and the time is 30min;

[0047] Step 3, add the dry mixture into the mixing tank, keep the temperature in the mixing tank at 160°C, stir at a stirring speed of 1000rpm, for 25 minutes, add asphalt, and stir and mix, and keep the temperature in the mixing tank at 170°C , the stirrin...

Embodiment 2-8

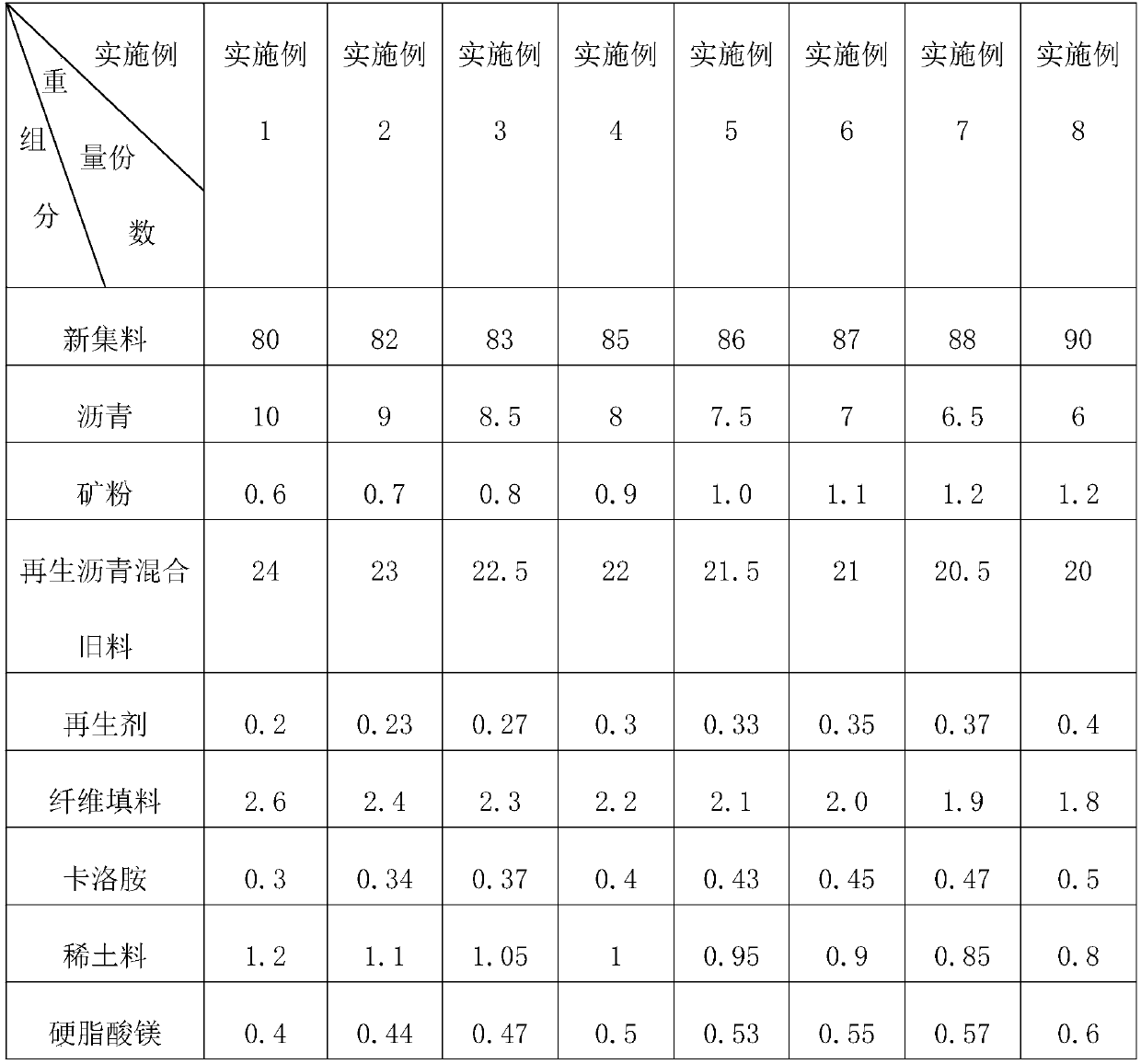

[0050] Example 2-8: An anti-seepage recycled asphalt concrete, the difference from Example 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0051] Each component and parts by weight thereof in table 1 embodiment 1-8

[0052]

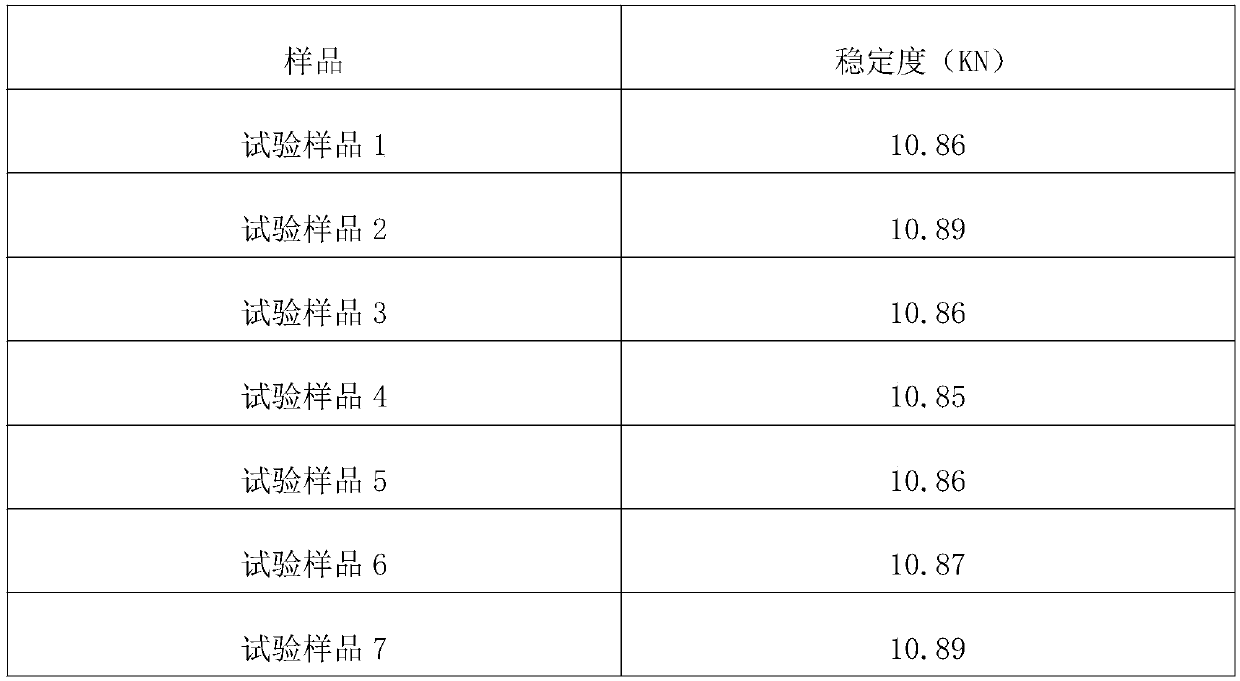

Embodiment 9

[0053] Example 9: A kind of anti-seepage recycled asphalt concrete. The difference from Example 1 is that the new aggregate mainly consists of particle sizes ranging from 0 to 3 mm, 3 to 5 mm, 5 to 13 mm, 13 to 20 mm, and 20 mm. The limestone of ~25mm is composed of 1.6:2.3:7.2:1:3.1 in parts by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com