Preparing method of graphene steel composite

A composite material and graphene technology, applied in the field of steel-based composite materials, can solve problems that need to be improved, and achieve the effects of avoiding excessive grain growth, eliminating component segregation, and simplifying process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The embodiment of the present invention provides a kind of preparation method of graphene steel composite material, comprising:

[0027] S10, providing a mixed solution, the mixed solution including an organic solvent, graphene powder and steel powder;

[0028] S20, drying the mixed liquid to obtain a mixed powder;

[0029] S30, loading the mixed powder after the drying treatment in a bag for vacuum degassing and sealing the bag;

[0030] S40, subjecting the sealing envelope loaded with the mixed powder to hot isostatic pressing, the temperature of the hot isostatic pressing is 920° C. to 1300° C., so that the mixed powder forms a composite material green body; and

[0031] S50, separating the composite material green body from the wrapping.

[0032] In the embodiment of the present invention, a graphene-steel composite material is prepared by mechanically mixing graphene powder and steel powder, vacuum pumping and hot isostatic pressing. Compared with steel without ...

Embodiment 1

[0066] Provide powder with the following quality: in the total weight of graphene powder and steel powder, 0.3% graphene powder, 1% non-graphite carbon, 17% Cr, 0.4% Mo, no more than 0.7 % of Mn, 0.2-0.45% of Si, not more than 0.23% of Cu, not more than 0.3% of Ni, not more than 0.035% of P, not more than 0.03% of S, and the balance is iron. The particle size of the steel powder was 50 μm.

[0067] Put the graphene powder and steel powder into a V-type powder mixer for 3 hours, add absolute ethanol to form a mixed solution, dry it under mechanical stirring at 25°C until the mixed solution is semi-dry, and then transfer it to a vacuum oven. Carry out thorough drying in a dry box at a drying temperature of 90°C to obtain a mixed powder;

[0068] Low-temperature ball milling is carried out on the mixed powder after the drying treatment, the temperature of the low-temperature ball mill is -80°C, and the ball milling time is 0.5h to 4h;

[0069] The mixed powder from ball milling...

Embodiment 2

[0073] This embodiment is basically the same as that of Embodiment 1, except that the temperature of the hot isostatic pressing is 980°C.

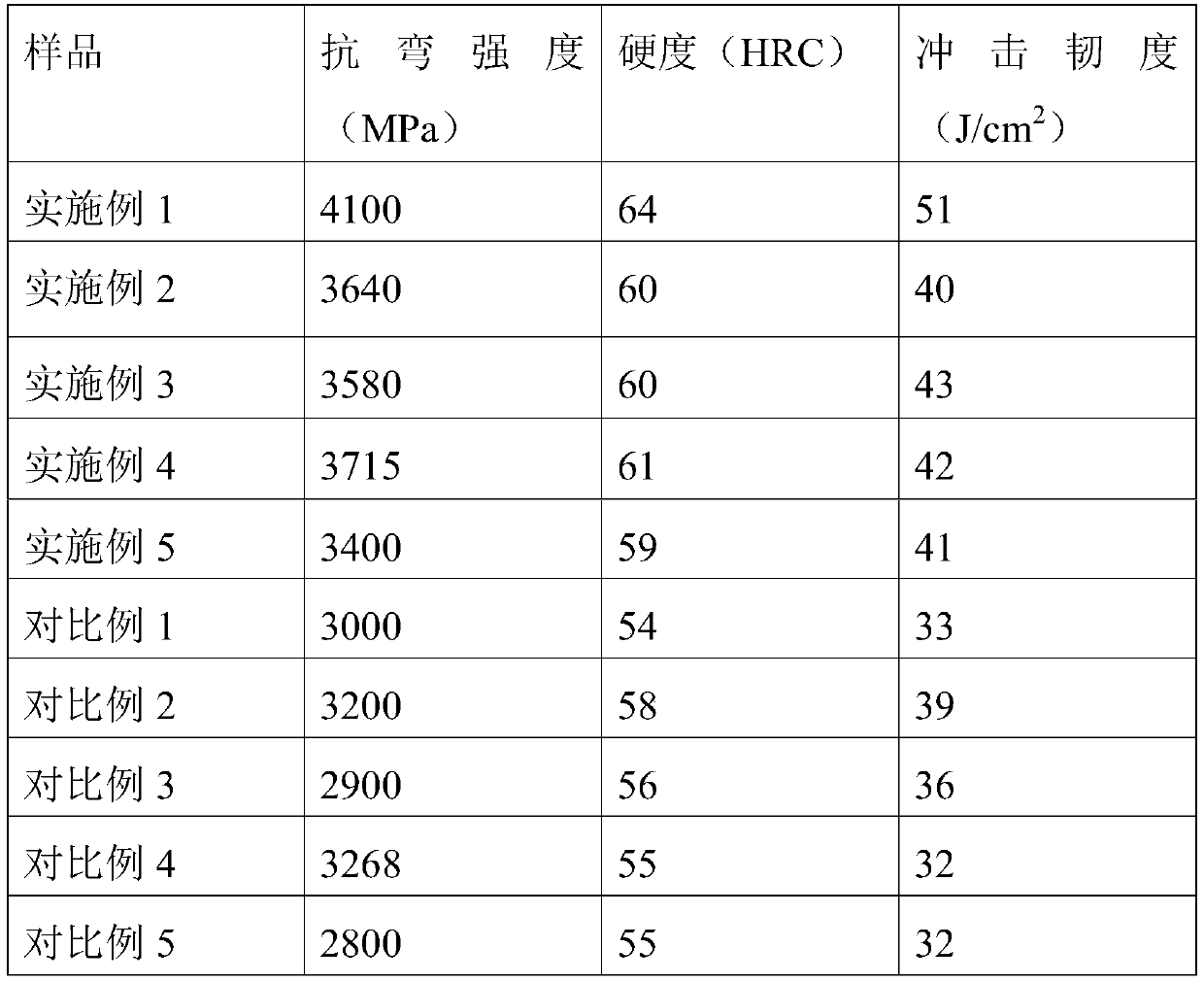

[0074] The mechanical properties of the prepared graphene-steel composite were measured, and the results are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com