Process and apparatus for producing alkane hydramine

An alkanolamine, regeneration process technology, applied in the directions of organic chemistry methods, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as insufficient production of dialkanolamines, and achieve the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0120] The present invention will be described in detail through the following examples, which should not be considered as a limitation to the present invention.

[0121] The invention is illustrated by the production of ethanolamine primarily using ethylene oxide as the alkylene oxide.

Embodiment 1-1

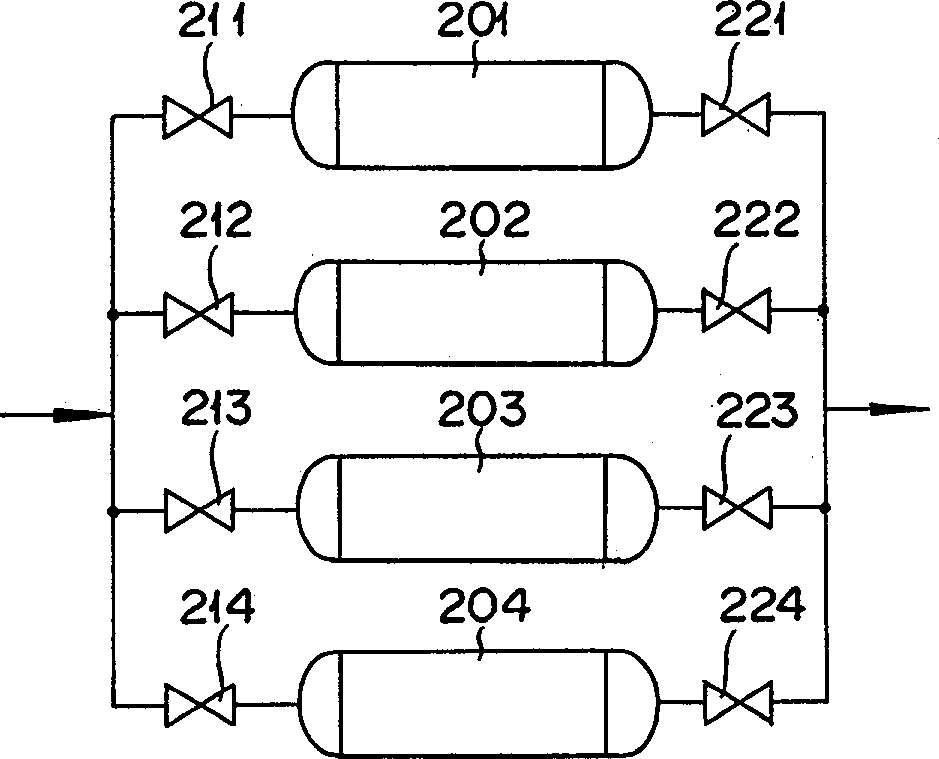

[0125] This example refers to a case where the regeneration process and the reaction process are repeatedly performed by using a single reactor. use Figure 4 The apparatus shown in was used to carry out the reaction. A stainless steel pipe having an inner diameter of 15 mm and a length of 400 mm, on which a heater for compensating heat radiation was wound and having a thermal insulation layer was used as the reactor 401 . Inside the reactor, there is installed a protective tube into which a thermocouple for measuring the temperature profile of the fixed catalytic layer can be inserted. Charge the catalyst A of 50ml in the reactor, and with 5 hours -1 (LHSV) The raw material (ammonia / ethylene oxide molar ratio: 14 / 1) heated to 60° C. by the preheater 402 was added thereto to carry out the reaction.

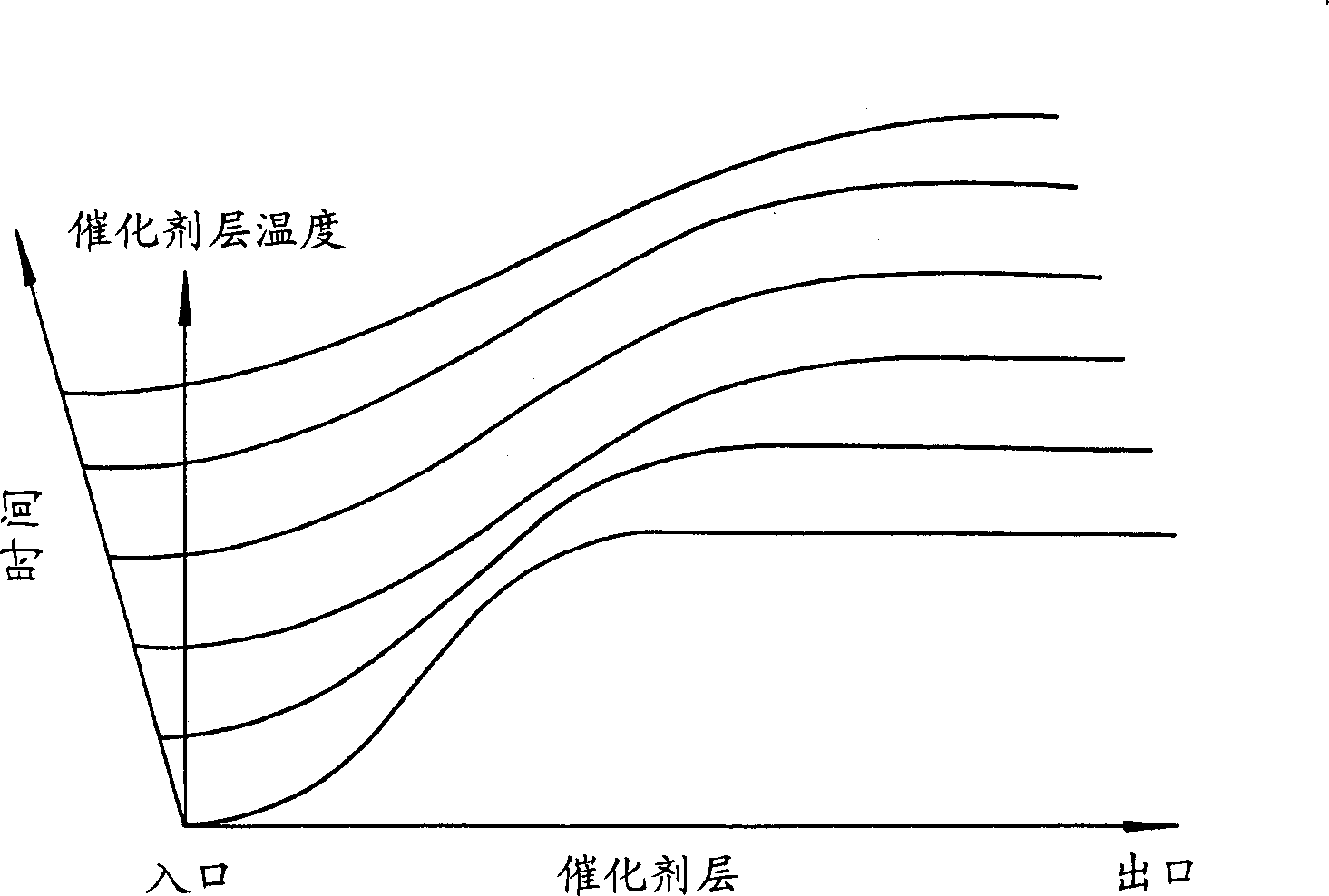

[0126] Although the temperature was increased to 150°C by the heat of reaction initially over a length of about 100 mm from the inlet, the temperature rose only to nearly 150°C...

Embodiment 1-2

[0130] This example is the case of using a single reactor in which the regeneration process and the reaction process are repeated. use Figure 4 The apparatus shown in was used to carry out the reaction. A stainless steel pipe having an inner diameter of 15 mm and a length of 400 mm, on which a heater for compensating for heat radiation was wound and having a thermal insulation layer was used as the reactor 401 . Inside the reactor, there is installed a protective tube into which a thermocouple for measuring the temperature profile of the fixed catalytic layer can be inserted. Charge the catalyst A of 50ml in the reactor, and with 5 hours -1 (LHSV) The raw material (ammonia / ethylene oxide molar ratio: 14 / 1) heated to 60° C. by the preheater 402 was added thereto to carry out the reaction.

[0131]Although the temperature was increased to 150°C initially by the heat of reaction over a length of about 100 mm from the inlet, the temperature rose only to nearly 150°C after 500 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com