Magnesium alloy surface treatment method utilizing combination of laser beams and coated layer

A surface treatment, magnesium alloy technology, applied in coating, metal material coating process, fusion spraying, etc., can solve the problem of poor corrosion resistance of magnesium alloy surface, improve corrosion resistance, overcome low bonding strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

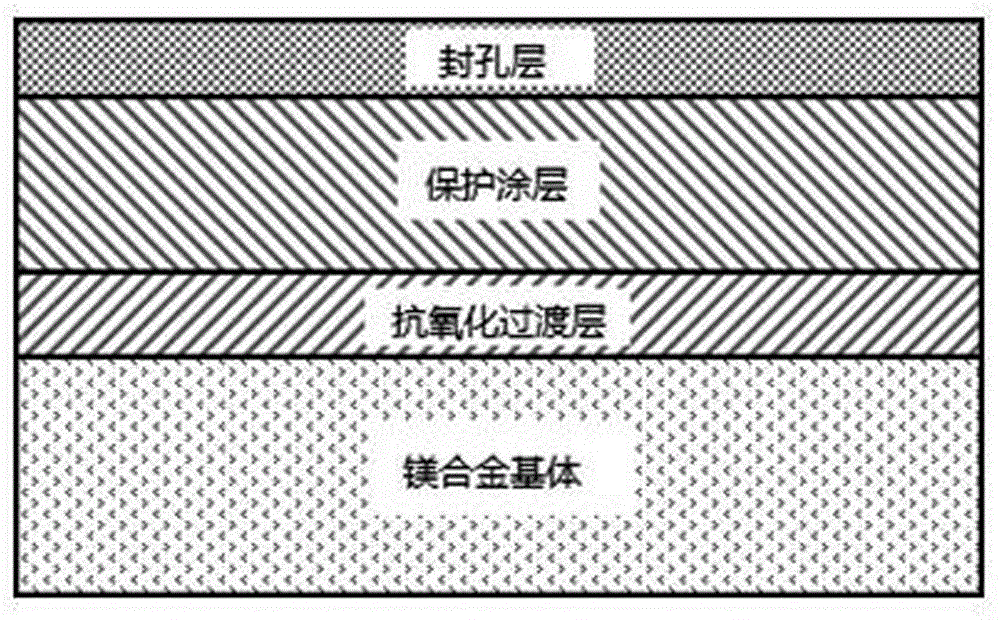

[0023] First, the AZ91D magnesium alloy sample is cleaned and polished, and then Al+Al with a thickness of 1mm is preset on the surface of the sample. 2 o 3 The mixed powder with a mass ratio of 6:1 is laser cladding with a 500W YAG solid-state pulse laser. The cladding process is protected by argon gas, and an anti-oxidation transition layer is obtained on the surface of the magnesium alloy sample.

[0024] Then use plasma spraying (one of the thermal spraying methods) to prepare Al 2 o 3 For protective coating, the power is 35KW, the spraying distance is 100mm, the powder feeding speed is 45g / min, and the thickness of the sprayed coating is about 500μm.

[0025] Finally, laser remelting is used to seal the coating. Before sealing, the magnesium alloy substrate is preheated (preheated at 100°C for 36 hours), and then remelted with a laser with a power of 2500W.

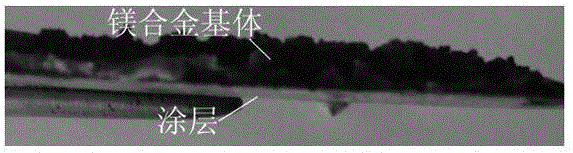

[0026] The macroscopic morphology of the prepared magnesium alloy samples after soaking in salt solution for 48...

Embodiment 2

[0028] The difference from Example 1 is that the anti-oxidation transition layer adopts Al and Al with a mass ratio of 4:1 2 o 3 mixed powder. The mixed powder in the above ratio is used as the anti-oxidation transition layer cladding material, because Al 2 o 3 The addition of reinforcement phase particles significantly improves the surface hardness and wear resistance of the magnesium alloy after cladding (the microhardness is 258HV, and the substrate hardness of the magnesium alloy before cladding is 80HV). If you continue to increase the Al in the mixed powder 2 o 3 content, the surface hardness of the cladding layer increases less, and due to Al 2 o 3 Large difference in physical properties between magnesium alloys, excessive Al 2 o 3 It is easy to cause microcracks, affect the quality of the cladding layer, and seriously reduce the corrosion resistance of the anti-oxidation transition layer.

Embodiment 3

[0030] The difference from Example 1 is that the anti-oxidation transition layer adopts Al and Al with a mass ratio of 8:1 2 o 3 mixed powder. At this time, the Al content in the cladding material is relatively high (Al 2 o 3 The content is relatively small), and the surface hardness of the sample reaches 160HV after cladding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com