Tungsten nanoparticle-based enhanced light metal-based composite material and preparation method thereof

A nanoparticle and composite material technology, applied in the field of materials, can solve the problems of poor bonding between the metal matrix and the particle interface, uneven particle dispersion, etc., and achieve the effect of improving high temperature mechanical properties, overcoming uneven distribution, and improving strength and toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment discloses the preparation method of tungsten nanopowder, specifically:

[0037] Step 1. Use paratungstinate as raw material, dissolve in deionized water under the condition of heating and stirring, add citric acid as complexing agent, and dissolve in deionized water together according to the molar ratio of metal ion and complexing agent citric acid 2:1 Form a sol with ionized water, continue to heat and stir to form a gel, then dry in a drying oven at 120°C for 4 hours, and then calcinate at 550°C for 5 hours in an air environment to obtain tungsten oxide powder;

[0038] Step 2. Place the tungsten oxide powder prepared in step 1 in a hydrogen atmosphere and keep it at 700° C. for 1 hour for reduction to obtain tungsten nanopowder.

Embodiment 2

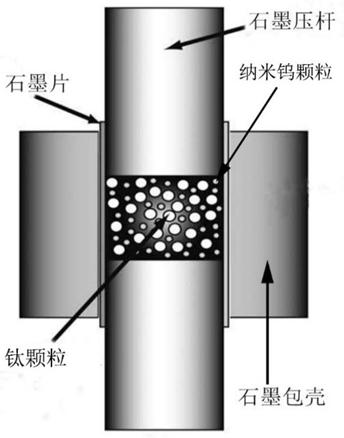

[0040] as attached figure 1 As shown, this embodiment discloses the preparation method based on tungsten nanoparticles reinforced titanium-based composite material of the present invention, specifically:

[0041] The tungsten nanopowder and the pure titanium powder with a particle size of 50 μm prepared according to the method in Example 1 were placed in a 1L ball mill jar at a mass ratio of 1:24, wherein the amounts of tungsten nanopowder and titanium powder were respectively 0.25 g and 6g; then add 300ml of alcohol for ball milling at a speed of 300r / min. After the ball milling time is 10 hours, pour the mixture of ball milled powder and alcohol into a suction filtration device for suction filtration, and place the powder after suction filtration Dry in a vacuum oven at a temperature of 100° C. for 10 hours to finally obtain ball-milled tungsten-dispersed titanium powder.

[0042] The powder of tungsten-dispersed titanium is placed in a graphite abrasive tool and pressed in...

Embodiment 3

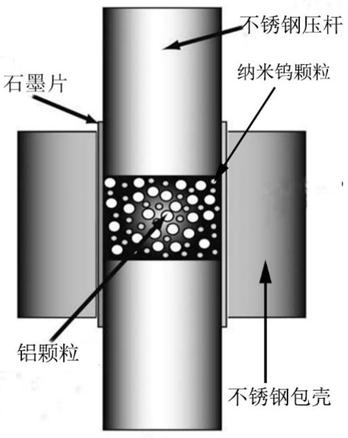

[0045] as attached figure 2As shown, this embodiment discloses the preparation method based on tungsten nanoparticles reinforced titanium-based composite material of the present invention, specifically:

[0046] Put the tungsten nanopowder and the pure aluminum powder with a particle size of about 80 μm prepared according to the method in Example 1 into a 1L ball milling pot at a mass ratio of 1:10, wherein the tungsten nanopowder is 0.25g, and the pure aluminum powder is 2.5g g; then add 300ml of alcohol for ball milling at a speed of 200r / min. After 20 hours of ball milling, pour the mixture of ball milled powder and alcohol into a suction filtration device for suction filtration, and vacuum dry the powder after suction filtration. The oven was dried at 100°C for 10 hours to finally obtain ball-milled tungsten-dispersed aluminum powder.

[0047] The powder of tungsten-dispersed aluminum is placed in a stainless steel abrasive tool and pressed into shape, and then sintered ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com