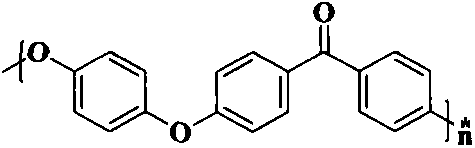

Preparation method of polyetheretherketone nonstick coating material

A technology of non-stick coating and polyether ether ketone, applied in the direction of coating, etc., can solve the problems of high cost, poor thermal conductivity, unstable inorganic filler, etc., to improve thermal conductivity and impact strength, and overcome poor dispersion , good effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

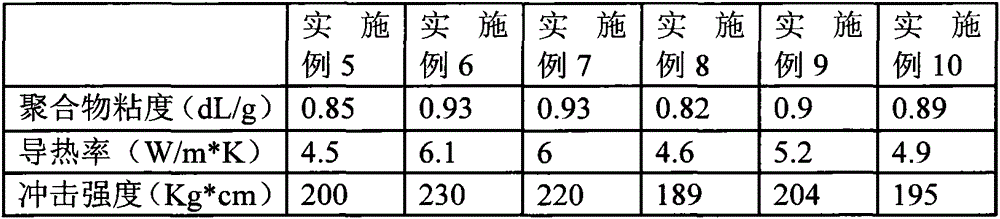

Examples

Embodiment 1 to Embodiment 6

[0023] 1) Weigh 10g multi-walled carbon nanotube MWCNT, add it to a 1000ml round bottom flask, add 100ml concentrated HNO 3 and 300ml concentrated H 2 SO 4 , magnetically stirred for 0.5h, and then stirred and reacted in an oil bath at 80°C for 8h. Add the reactant dropwise to ice water, let it stand, pour the upper layer liquid, continue to dilute with distilled water, let it stand until the upper layer becomes a clear liquid, filter out the product, wash the filter cake with distilled water, until the pH of the filtrate is 7, and dry it in vacuum at 50 °C The product is ground to obtain the first reactant, which is stored in a desiccator for future use.

[0024] above concentrated HNO 3 The mass concentration of 96-98%, concentrated H 2 SO 4 The mass concentration is 97-98%.

[0025] 2) Weigh 3g of the first reactant, 200ml of thionyl chloride and 30ml of DMF and add them to a 500ml three-neck flask, add a magnet, install a reflux device and an exhaust gas absorption d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com