Aqueous nano polyaniline-epoxy acrylic resin conductive anticorrosion primer base

An epoxy acrylic and nano-polyaniline technology, applied in anti-corrosion coatings, conductive coatings, coatings, etc., can solve the problems of affecting the conductivity and anti-corrosion effect of coatings, poor dispersion of polyaniline particles, etc., to solve the problem of poor anti-corrosion performance , Improve storage stability and solve the effect of dispersion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

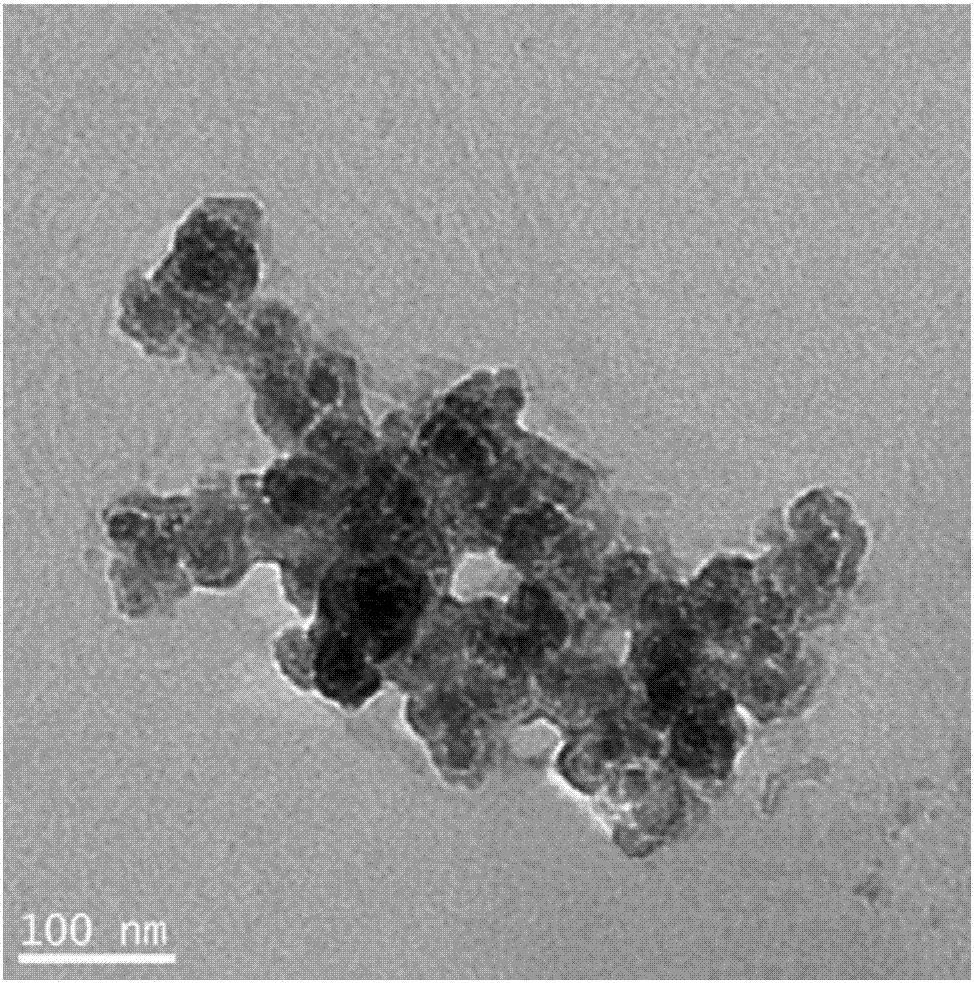

Image

Examples

Embodiment 1

[0033] 1, the preparation of nano polyaniline-epoxyacrylic resin mixture: ammonium persulfate 10Wt%, dodecylbenzenesulfonic acid 11Wt%, water 40Wt%, castor oil 22Wt%, epoxy acrylic resin 11Wt%, aniline 6%, React at room temperature for 6 h to obtain a mixture of nano polyaniline-epoxy acrylic resin.

[0034] 2. Preparation of water-based nano polyaniline-epoxy acrylic resin conductive anti-corrosion primer coating: nano polyaniline-epoxy acrylic resin mixture 0.5Wt%, acrylic acid antirust emulsion 60Wt%, coupling agent 0.4Wt%, film-forming aid 2Wt%, dispersant 0.3Wt%, preservative 0.5Wt%, wetting agent 0.5Wt%, thickener 0.8Wt%, neutralizer 1Wt%, antifreeze 5Wt%, defoamer 0.3Wt%, leveling 0.2wt% of agent, 28wt% of filler and 0.5wt% of initiator are obtained by stirring and mixing uniformly.

[0035] The water-based nano-polyaniline-epoxy acrylic resin conductive anti-corrosion primer coating was poured on glass plates or sprayed on steel plates at room temperature, and cured a...

Embodiment 2

[0037] 1, the preparation of nano polyaniline-epoxyacrylic resin mixture: ammonium persulfate 9Wt%, dodecylbenzenesulfonic acid 13Wt%, water 36Wt%, castor oil 25Wt%, epoxy acrylic resin 15Wt%, aniline 2%, React at room temperature for 7 hours to obtain a mixture of nano polyaniline-epoxy acrylic resin.

[0038] 2. Preparation of water-based nano polyaniline-epoxy acrylic resin conductive anti-corrosion primer coating: nano polyaniline-epoxy acrylic resin mixture 0.3Wt%, acrylic acid antirust emulsion 50Wt%, coupling agent 0.2Wt%, film-forming aid 4.5wt%, dispersant 0.5wt%, preservative 0.7wt%, wetting agent 1wt%, thickener 3wt%, neutralizer 1.5wt%, antifreeze 7wt%, defoamer 0.2wt%, leveling 0.4wt% of the agent, 30wt% of the filler, and 0.7wt% of the initiator are obtained by stirring and mixing uniformly.

[0039] The water-based nano-polyaniline-epoxy acrylic resin conductive anti-corrosion primer coating was poured on the glass template at room temperature, or sprayed on th...

Embodiment 3

[0041] 1, the preparation of nano polyaniline-epoxyacrylic resin mixture: ammonium persulfate 5Wt%, dodecylbenzenesulfonic acid 10Wt%, water 36Wt%, castor oil 20Wt%, epoxy acrylic resin 25Wt%, aniline 4%, React at room temperature for 8 hours to obtain a mixture of nano polyaniline-epoxy acrylic resin.

[0042] 2. Preparation of water-based nano polyaniline-epoxy acrylic resin conductive anti-corrosion primer coating: nano polyaniline-epoxy acrylic resin mixture 0.7Wt%, acrylic acid antirust emulsion 55Wt%, coupling agent 0.7Wt%, film-forming aid 3.5wt%, dispersant 1wt%, preservative 1wt%, wetting agent 0.8wt%, thickener 5wt%, neutralizer 0.7wt%, antifreeze 8wt%, defoamer 0.5wt%, leveling agent 0.7wt%, filler 22wt%, initiator 0.4wt%, stirring and mixing to obtain.

[0043] The water-based nano-polyaniline-epoxy acrylic resin conductive anti-corrosion primer coating was poured on the glass template at room temperature, or sprayed on the steel plate, and cured at a constant tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tack-free time | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com