Wood preservative and preparation method thereof

A wood preservative, nano-copper oxide technology, applied in the direction of wood impregnation, impregnated wood, wood processing utensils, etc., can solve the problems of large environmental hazards, poor permeability, low loss resistance, etc., and achieve low environmental pollution and loss resistance Strong, good fixation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

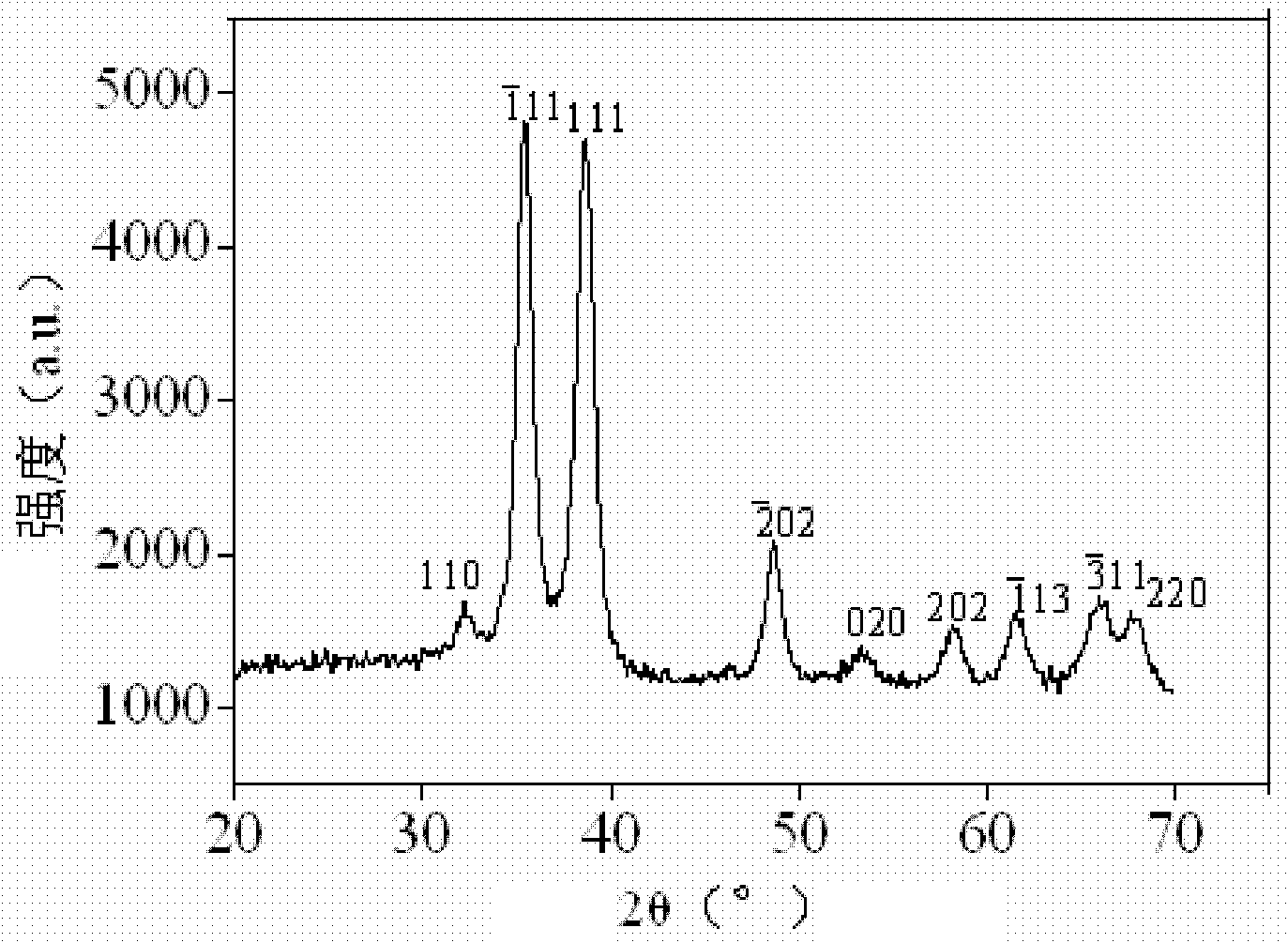

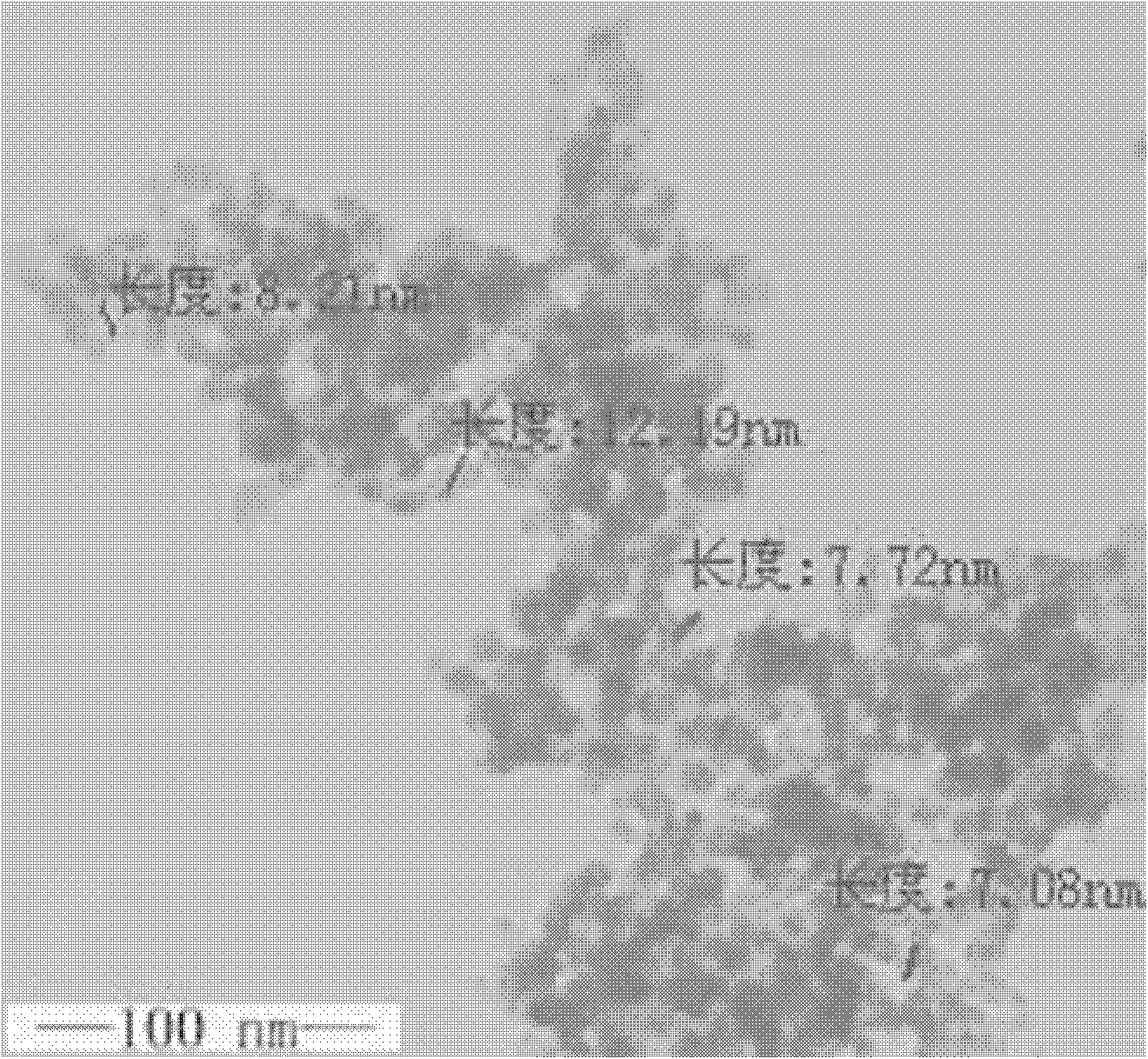

[0013] Specific embodiment one: wood preservative is made of nano-copper oxide, triammonium citrate, distilled water, chitosan and acetic acid solution among the present invention, and wherein, the mass ratio of nano-copper oxide and triammonium citrate is 1: 0.1~0.5, the mass ratio of chitosan and nano-copper oxide is 0.5-1.5:1, the mass ratio of chitosan and acetic acid is 1:0.5-1, the mass of distilled water is equal to the total of nano-copper oxide and triammonium citrate The mass ratio is 19-99:1.

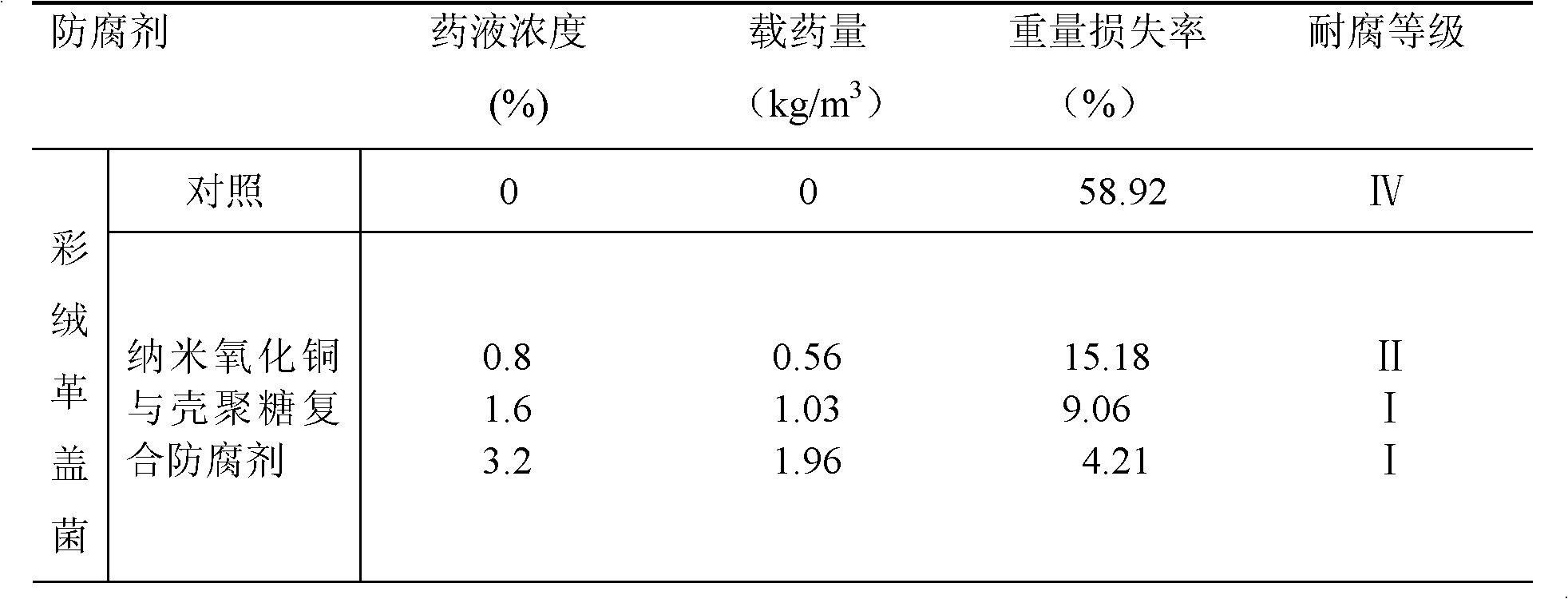

[0014] The wood preservative of the present embodiment is a dark brown viscous liquid, and the wood preservative is effective against wood decay fungus brown rot fungus—Gloeophyllum trabeum and white rot fungus—Coriolus versicolor It has obvious antibacterial effect. The copper fixation rate in the preservative described in this embodiment is very good, and has the advantages of good permeability and strong loss resistance. Using distilled water as a solvent has little envi...

specific Embodiment approach 2

[0015] Specific embodiment two: what this embodiment is different from specific embodiment one is: the particle diameter of described chitosan is 30~100 orders, and molecular weight is 3~800,000, and deacetylation degree is 85%~100% (deacetylation degree It is the ratio of the actual amino content to the theoretical amino content, and the amino content refers to the mass content). Others are the same as in the first embodiment.

specific Embodiment approach 3

[0016] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the mass ratio of chitosan to nano-copper oxide is 0.7-1.3:1. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com