Processing method for manufacturing large bamboo slip through side pressing bamboo plates

A processing method and bamboo board technology, which is applied in the field of bamboo product processing, can solve the problems of poor anti-mildew effect, rotten cavity, easy mildew, etc., and achieve the effect of improving anti-loss performance, not easy to lose, and high fixation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

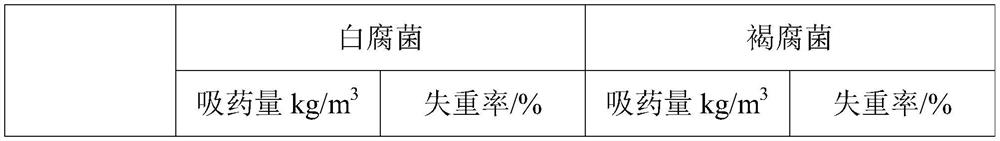

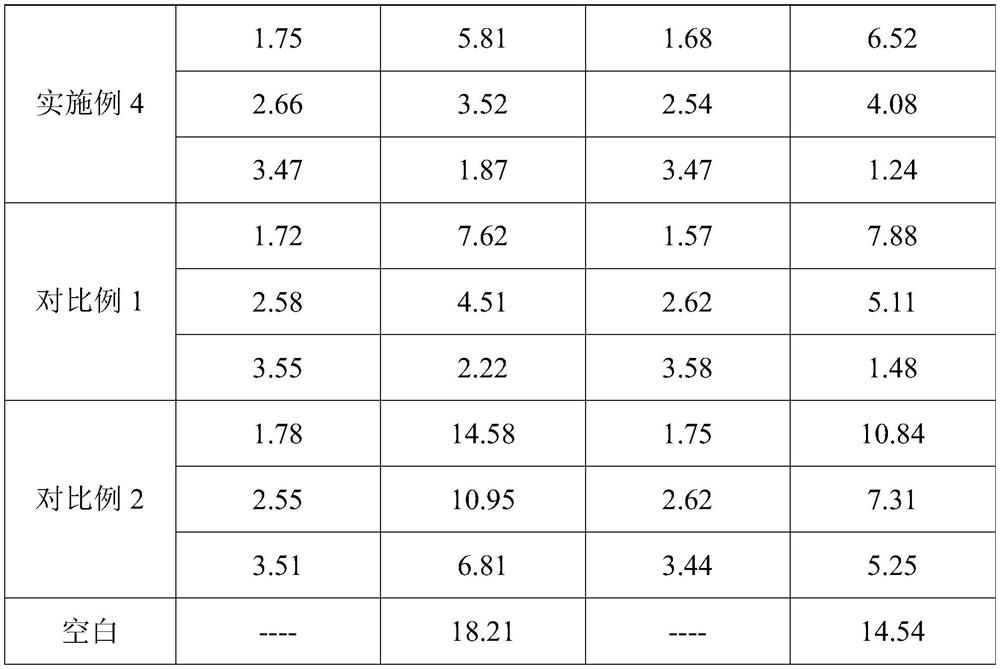

Examples

Embodiment 1

[0028] Preparation of carboxymethyl chitosan quaternary ammonium salt: Disperse 1 part of chitosan (deacetylation degree 95%) into 15 parts of isopropanol to swell for 40min, then slowly add 3.7 parts of 40wt% sodium hydroxide aqueous solution dropwise, dropwise After the addition, the water bath was heated to 45°C and reacted for 1.5 h; 1.3 parts of chloroacetic acid was slowly added dropwise to the reaction system, and the reaction was kept for 1.5 h; after the reaction was completed, the pH was adjusted to neutral, and the precipitate was cooled with anhydrous Ethanol washing, suction filtration to obtain light yellow powder solid; 1 part of light yellow powder solid is dissolved in 8 parts of absolute ethanol, the pH of the system is adjusted to 10, and then 7.5 parts of 50wt% 2,3-epoxypropyl group are slowly added dropwise The trimethylammonium chloride aqueous solution was reacted in a water bath at 75°C for 3 hours. After the reaction, the pH of the system was adjusted t...

Embodiment 2

[0030] A processing method for making large-scale bamboo slips by utilizing side-pressed bamboo boards proposed by the present invention comprises the following steps:

[0031] S1. Saw the side-pressed bamboo board according to the design size, and then finely grind and polish the whole piece to obtain the bamboo board;

[0032] S2, put the bamboo board into the antiseptic solution and vacuumize to 0.09MPa, hold for 30min, then pressurize to 1.2MPa, hold for 15min, take out, and dry until the moisture content of the bamboo board is 10%; wherein, the antiseptic solution includes the following qualities Percentage of raw materials: tebuconazole 0.5%, insecticide 0.1%, carboxymethyl chitosan quaternary ammonium salt 0.2% (prepared in Example 1), lauramidopropylamine oxide 0.5%, fatty alcohol polyoxyethylene Ether AEO-34%, antioxidant propyl gallate 0.01%, antifreeze 0.2%, ethanol 2%, isopropanol 4%, and the balance is water.

[0033] S3. Spray the back cover of the bamboo sheet ...

Embodiment 3

[0039] Compared with Example 2, the difference is only in that the step S2 is different, and the specific differences are as follows:

[0040] S2, put the bamboo board into the antiseptic solution and vacuumize to 0.09MPa, hold for 30min, then pressurize to 1.2MPa, hold for 15min, take out, and dry until the moisture content of the bamboo board is 10%; wherein, the antiseptic solution includes the following qualities Percentage of raw materials: tebuconazole 2.5%, propiconazole 2.5%, insecticide 0.8%, carboxymethyl chitosan quaternary ammonium salt 2% (prepared in Example 1), lauramide propyl amine oxide 2% , fatty alcohol polyoxyethylene ether AEO-5 0.5%, antioxidant tert-butyl hydroquinone 0.05%, antifreeze 2%, propanol 4%, isopropanol 5%, cyclohexane 1%, the balance for water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com