Method for preparing high-yield carbon quantum dots

A carbon quantum dot, high-yield technology, which is applied in the field of carbon quantum dot preparation, can solve the problems of difficulty in realizing large-scale production promotion, low yield of carbon quantum dots, and cumbersome process steps, etc., and achieves a wide range of preparation temperature and high yield. And the effect of high quantum yield and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

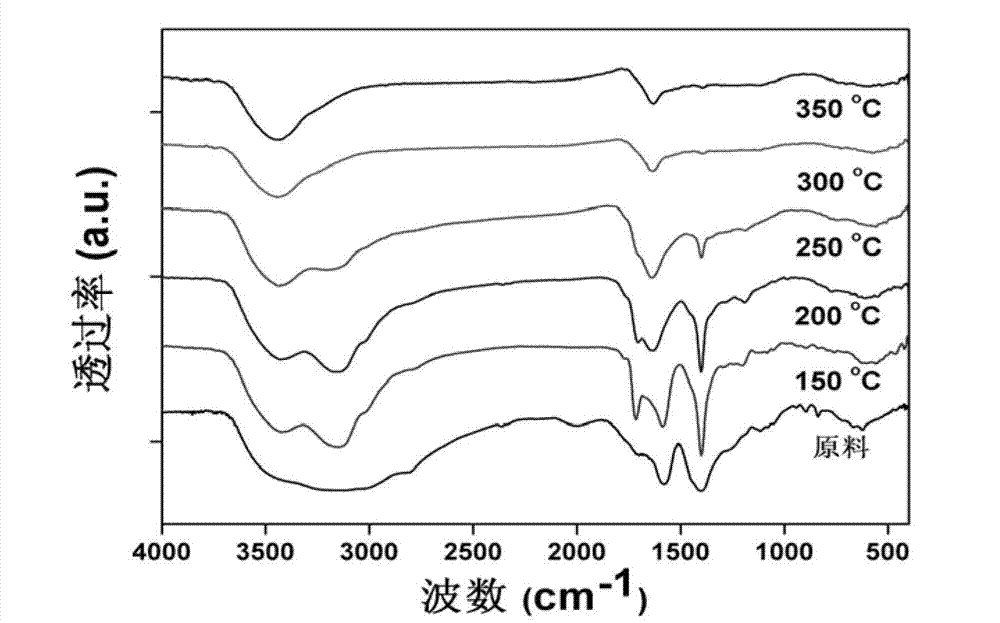

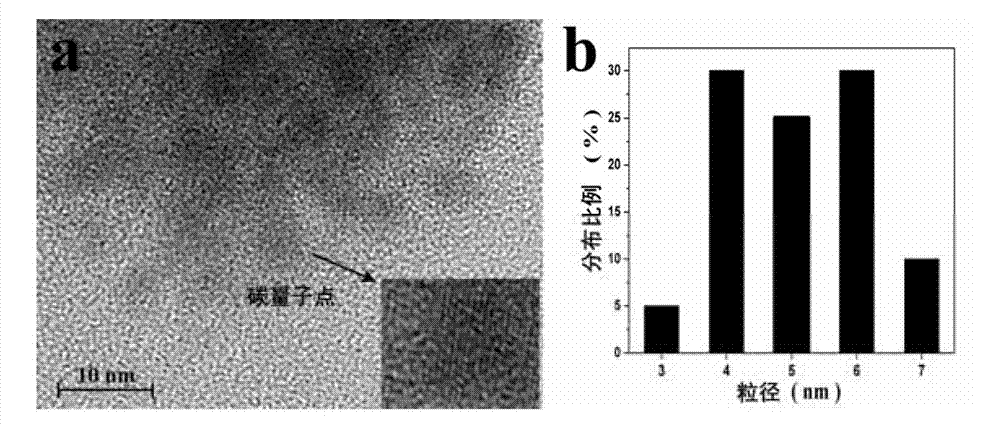

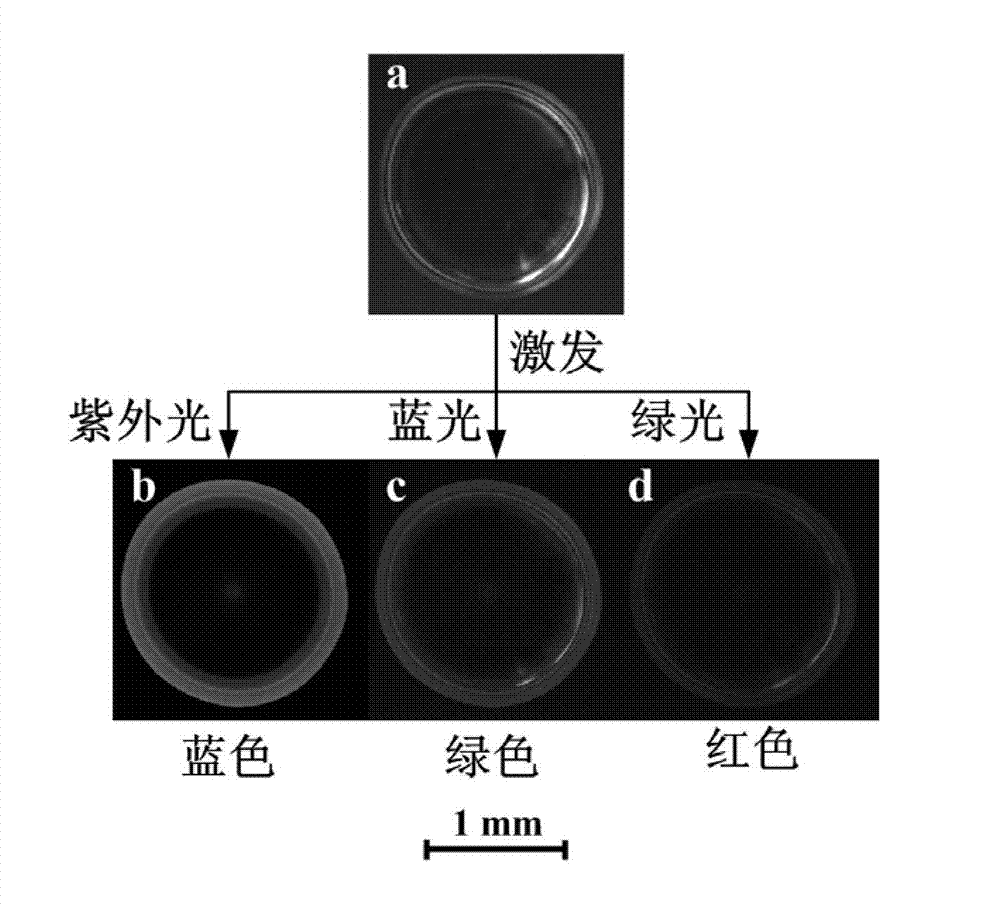

[0026] A preparation method for high-yield carbon quantum dots, comprising the following steps:

[0027] (1) Put ammonium citrate with a mass of 0.5g into a muffle furnace, set the heating rate at 10°C / min to raise the temperature, and react at 150°C for 2.5h to obtain a cracked product;

[0028] (2) Grind the cracked product into powder, add 50ml of ethanol and stir for 6h, centrifuge at 4500rpm for 12min, remove insoluble matter, and obtain a brown ethanol solution containing carbon quantum dots;

[0029] (3) drying the ethanol solution containing carbon quantum dots to obtain carbon quantum dots. The yield is 17.5%, and the quantum yield is 26.1%;

Embodiment 2

[0031] A preparation method for high-yield carbon quantum dots, comprising the following steps:

[0032] (1) Put 0.5 g of ammonium dihydrogen citrate into a muffle furnace, set the heating rate at 10°C / min to raise the temperature, and react at 200°C for 4 hours to obtain the cracked product;

[0033] (2) Grind the lysed product into powder, add 50ml of ethanol and stir for 5h, centrifuge at 4000rpm for 15min, remove insoluble matter, and obtain a brown ethanol solution containing carbon quantum dots;

[0034] (3) drying the ethanol solution containing carbon quantum dots to obtain carbon quantum dots. The yield is 13.5%, and the quantum yield is 23.7%;

Embodiment 3

[0036] A preparation method for high-yield carbon quantum dots, comprising the following steps:

[0037] (1) Put ammonium citrate with a mass of 0.5g into a tubular electric furnace, set the heating rate at 50°C / min to raise the temperature, and react at 250°C for 2 hours to obtain a cracked product;

[0038] (2) Grind the cracked product into powder, add 50ml of ethanol and stir for 5h, centrifuge at 6000rpm for 10min, remove insoluble matter, and obtain a brown ethanol solution containing carbon quantum dots;

[0039] (3) drying the ethanol solution containing carbon quantum dots to obtain carbon quantum dots. The yield is 2.1%, and the quantum yield is 22.9%;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com