On-line treatment method of acidic etching solution

A technology of acid etching solution and treatment method, which is applied in the direction of improving process efficiency, etc., can solve the problems of increasing operating cost, shortening service life, increasing the volume of etching solution, etc., and achieves reduced operating cost, strong oxidation resistance, and reduced waste The effect of liquid volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

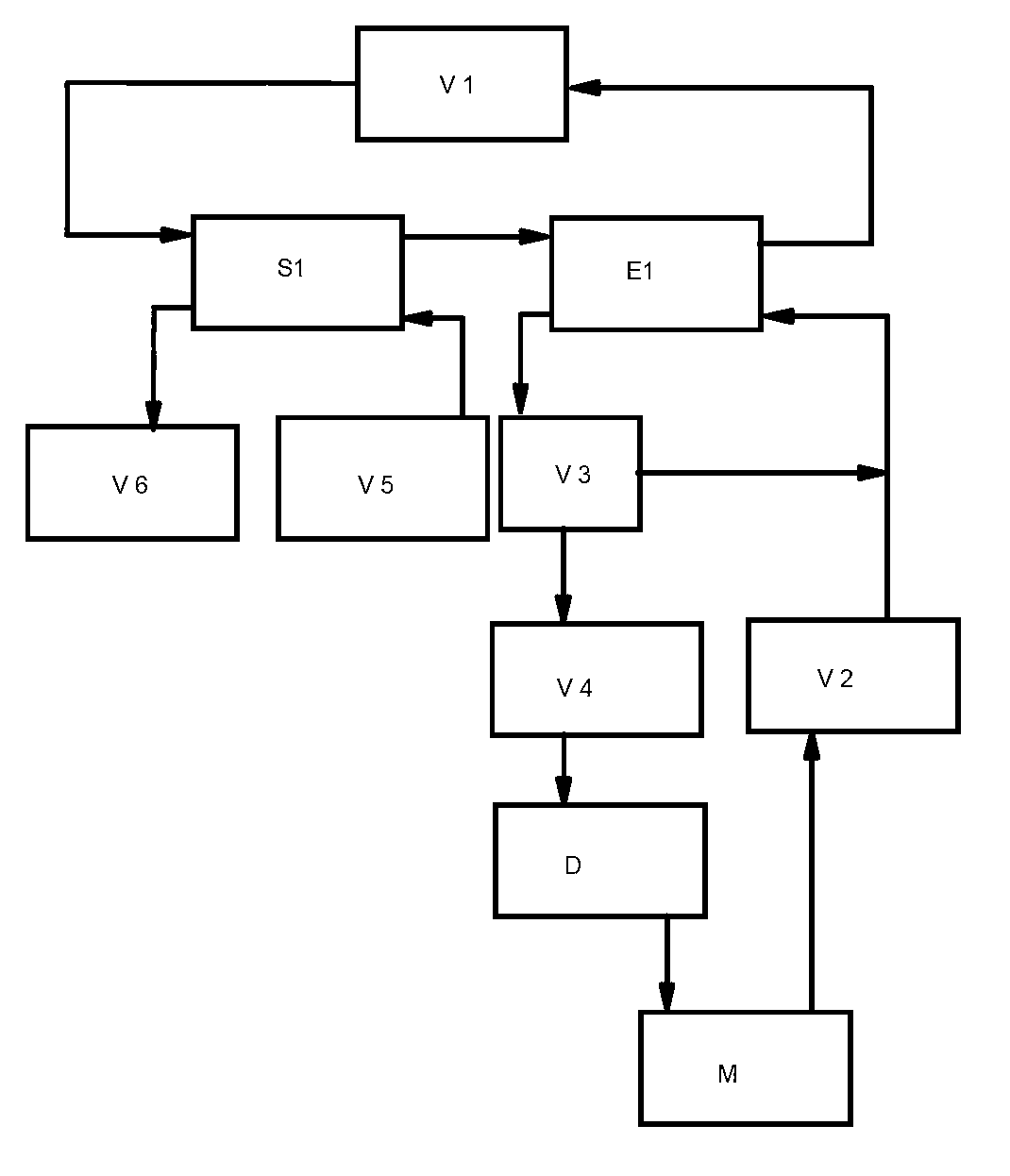

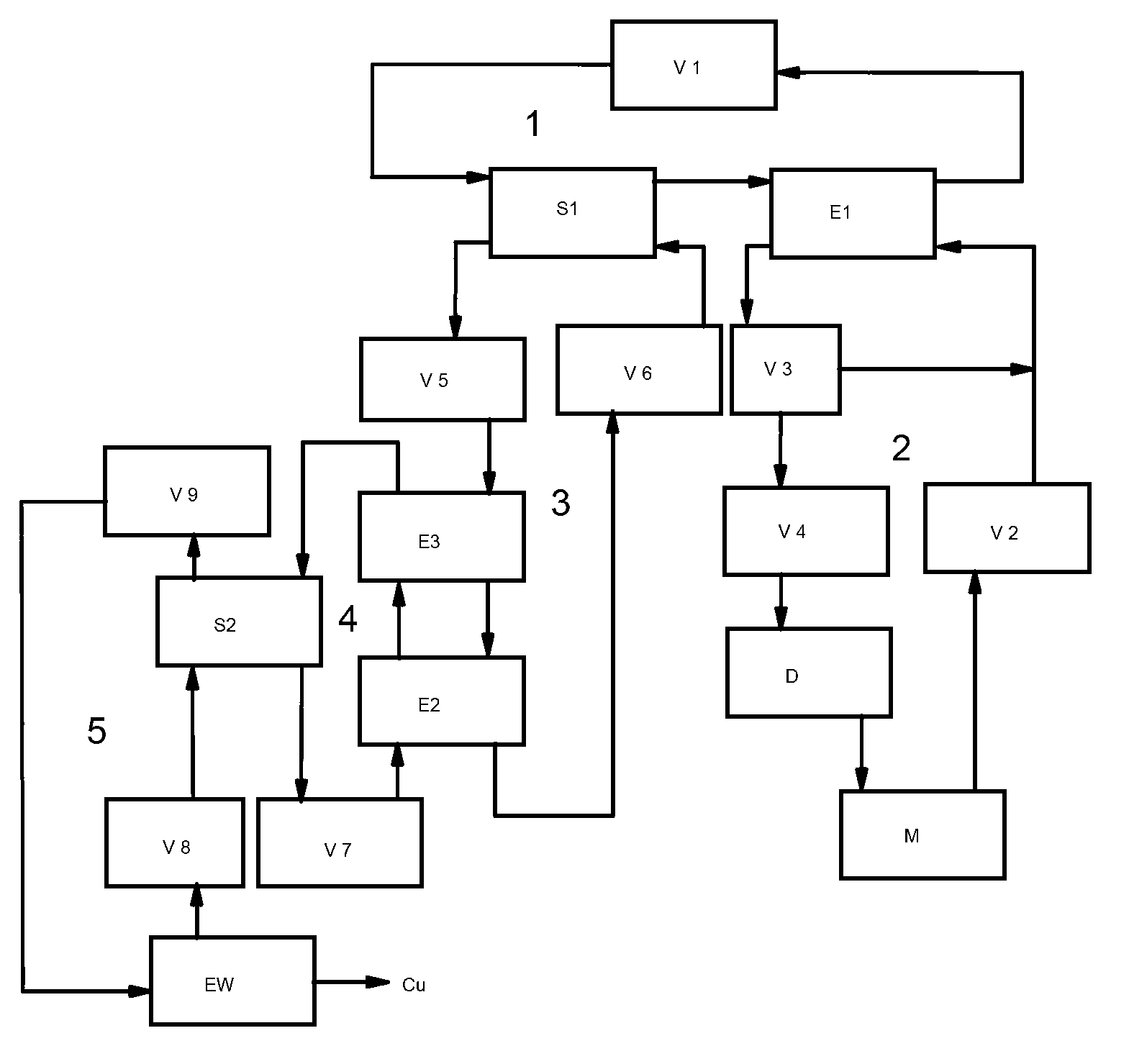

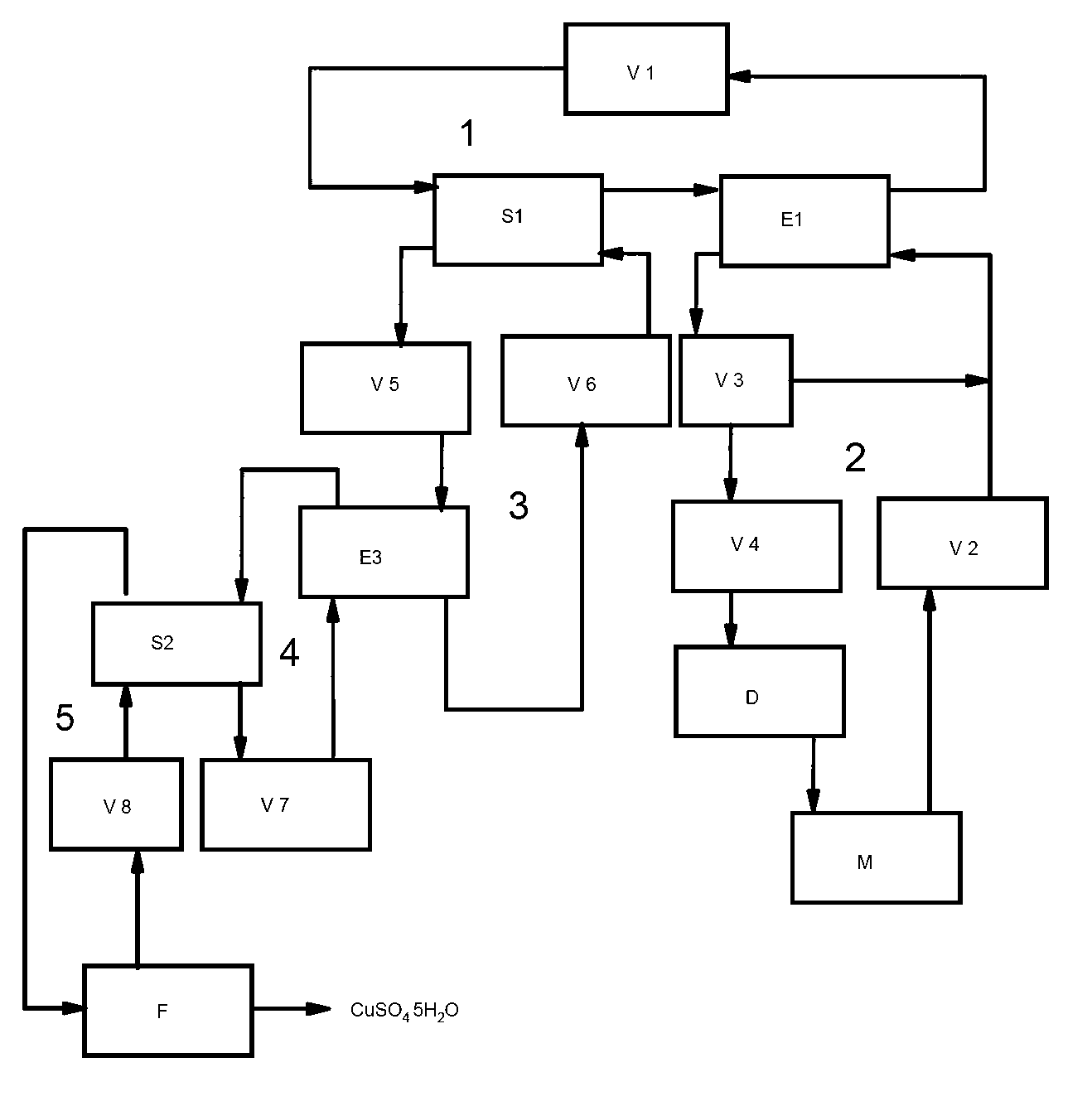

Method used

Image

Examples

Embodiment 1

[0058] The feature of this embodiment is that the acidic etching solution is treated with the pyridine carboxylate extractant Mextral CLX-50 and the hydroxime extractant Mextral984H. The acidic etching solution is directly extracted with pyridine carboxylate, and the copper-loaded pyridine carboxylate is back-extracted with water. The copper-containing aqueous solution after stripping is directly extracted with Mextral984H, and the copper-loaded Mextral984H is back-extracted with copper-poor electrolyte (180g / L sulfuric acid, 30g / L Cu). The copper content of the acidic etching solution is 177.81g / L, the concentration of hydrochloric acid is 1.6mol / L, and the pyridine carboxylate used is 3,5-pyridine dicarboxylate bis(isotridecyl alcohol) ester (extractant: diluent=1:3.5( w / w)), the hydroxime extractant is Mextral984H (extractant: diluent = 1:2 (w / w)), and the ratio of extraction and stripping is 1:1. Pyridine carboxylate uses one-stage extraction and one-stage stripping, and ...

Embodiment 2

[0063] The feature of this embodiment is that the acidic etching solution is treated with the pyridine carboxylate extractant Mextral CLX-50 and the β-diketone extractant Mextral 54-100. The acidic etching solution is directly extracted with pyridine carboxylate, and the copper-loaded pyridine carboxylate is back-extracted with 7.7% trisodium citrate aqueous solution. The copper-containing aqueous solution after stripping is adjusted to pH=10-12 with 40% sodium hydroxide solution, and then extracted with Mextral54-100, and copper sulfate solution (160g / L sulfuric acid, 60g / L Cu) back extraction. The copper content of the acidic etching solution is 177.81g / L, the concentration of hydrochloric acid is 1.6mol / L, and the pyridine carboxylate used is 3,5-pyridine dicarboxylate bis(isotridecyl alcohol) ester (extractant: diluent=1:3.5( w / w)), the β-diketone extractant is Mextral54-100 (extractant: diluent = 1:3 (w / w)), and the ratio of extraction and stripping is 1:1. Both extrac...

Embodiment 3

[0068] The feature of this embodiment is that the acidic etching solution is treated with pyridine carboxylate extractant Mextral CLX-50 alone. The acidic etching solution is directly extracted with pyridine carboxylate, and the copper-loaded pyridine carboxylate is back-extracted with water. The copper-containing aqueous solution after stripping is neutralized with 40% sodium hydroxide solution to pH = 9-10, and blue copper hydroxide precipitates are obtained. After the precipitate was filtered out and washed with water three times, it was burned in a muffle furnace at 800°C for 5 hours to obtain black copper oxide powder. The copper content of the acidic etching solution is 177.81g / L, the concentration of hydrochloric acid is 1.6mol / L, and the pyridine carboxylate used is 3,5-pyridine dicarboxylate bis(isotridecyl alcohol) ester (extractant: diluent=1:3.5( w / w)), the extraction ratio is O / A=4:1, and the stripping ratio is O / A=1:1. One-stage extraction and one-stage strippi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com