Self-cleaning hydrophilic composite material and preparation method thereof

A composite material and self-cleaning technology, applied in the field of self-cleaning materials, can solve the problems of short superhydrophilic validity time, single function, and inability to have both superhydrophilicity at the same time, and achieve extended validity time and simple and controllable process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

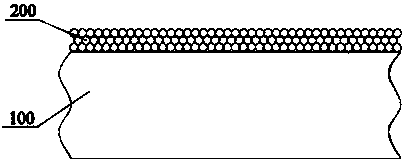

[0028] The present invention also provides a preparation method of the self-cleaning hydrophilic composite material, comprising the following steps:

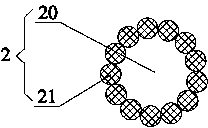

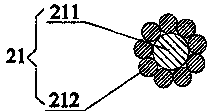

[0029]S10. The negatively charged PS spherical nanoparticles are adsorbed and wrapped on the surface of the composite polyelectrolyte through electrostatic adsorption, and then immersed in the suspension of the composite particle, and continue to adsorb and wrap the composite particle on the surface of the composite polyelectrolyte; the composite particle is the core Shell clad structure, where the core material is SiO 2 Nanoparticles, shell material is TiO 2 , shell material TiO 2 The particle size is smaller than the core material SiO 2 particle size;

[0030] S20, alternately repeating the steps of wrapping and adsorbing composite polyelectrolytes and composite particles in step S10 for 1-5 times to obtain a suspension system in which several layers of composite polyelectrolytes and several layers of composite particles ar...

Embodiment 1

[0049] (1) Add 1wt% negatively charged PS spherical nanoparticle aqueous suspension (PS particle size is 50nm) to PDDA and PSS aqueous solution with equal volume concentration of 2mg / mL successively, so that PS spherical nanoparticles are electrostatically adsorbed one layer in turn PDDA and a layer of PSS are then concentrated by vacuum evaporation to form a first suspension in which PS is coated with a composite polyelectrolyte layer (ie, the first coated PS) with a content of 1 wt%.

[0050] (2) Prepare SiO by the following method 2 / TiO 2 Core-shell composite particle suspension: ①. Based on nano-silica (1115, 15%, 4nm) from Nalco Company in the United States, add deionized water to adjust the mass fraction of silica to 1%, and adjust the pH of the sol to 2.5; ②. Under stirring conditions, for every 100 parts by mass of the above SiO2 sol, slowly drop 2.5 parts by mass of ethyl orthosilicate accordingly, stir for 1 hour after the addition is completed, and then drop 5 par...

Embodiment 2

[0057] The same steps as in Example 1 were used to prepare the self-cleaning hydrophilic composite glass S20 of this example, the difference being:

[0058] In step (1), the PS particle size is 100nm, the PS content in the PS spherical nanoparticle aqueous suspension is 2wt%, and the volume concentration of the PDDA aqueous solution and the PSS aqueous solution are both 3mg / mL;

[0059] In step (2), in the composite particle suspension, SiO 2 / TiO 2 The particle size of core-shell composite particles is 7nm, of which SiO 2 The particle size is 5nm, TiO 2 The particle size is 1nm;

[0060] In step (3), alternately repeat the electrostatic adsorption polyelectrolyte in step (1) and step (2) once each;

[0061] In step (4), the volume concentrations of the PDDA aqueous solution and the PSS aqueous solution are both 3 mg / mL, and the number of alternately adsorbed PDDA layers and PSS layers on the surface of the glass substrate is 3 layers;

[0062] In step (5), the immersion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com