Preparation method of anode active material

A negative electrode active material, selected technology, applied in battery electrodes, structural parts, electrical components, etc., can solve problems such as unfavorable commercial applications, difficult to prepare fine particles, specific capacity attenuation, etc. Guaranteed uniformity and stability, preventing contact and agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a preparation method of a pure-phase nanometer lithium titanate negative electrode active material. The steps of the method include: a. adding a titanium source and an organic carbon source into an organic solution with a pH value of 0-6 to form a mixed solution;

[0024] Wherein, the titanium source is selected from one or more of titanium isopropoxide, tetrabutyl titanate, metatitanic acid, titanium tetrachloride or titanyl sulfate;

[0025] b. Add an oxidizing agent to the above mixed solution, react at 20-80°C for 1-24h, then separate the precipitate, wash with water, and dry to obtain a titanium-containing precursor;

[0026] c. Mixing and ball-milling the titanium-containing precursor obtained in step b with a lithium source, and then calcining under an inert atmosphere. The lithium titanate composite material prepared by the method of the present invention has few impurity phases, the prepared lithium titanate particles are nanoscale, and ...

Embodiment 1

[0039] (1) Preparation of negative electrode active material

[0040] Dissolve 145ml of 37% HCl in 1800ml of ethanol (pH=1), stir, add 30ml of aniline, then slowly drop 265ml of titanium isopropoxide into the solution, stir thoroughly for 1h, and then slowly add 10ml of H 2 o 2 Raise the temperature to 80°C for 5h, filter, wash and dry repeatedly with distilled water and ethanol to obtain a titanium-containing precursor, roast at 400°C for 4h under the protection of Ar atmosphere, cool, and grind.

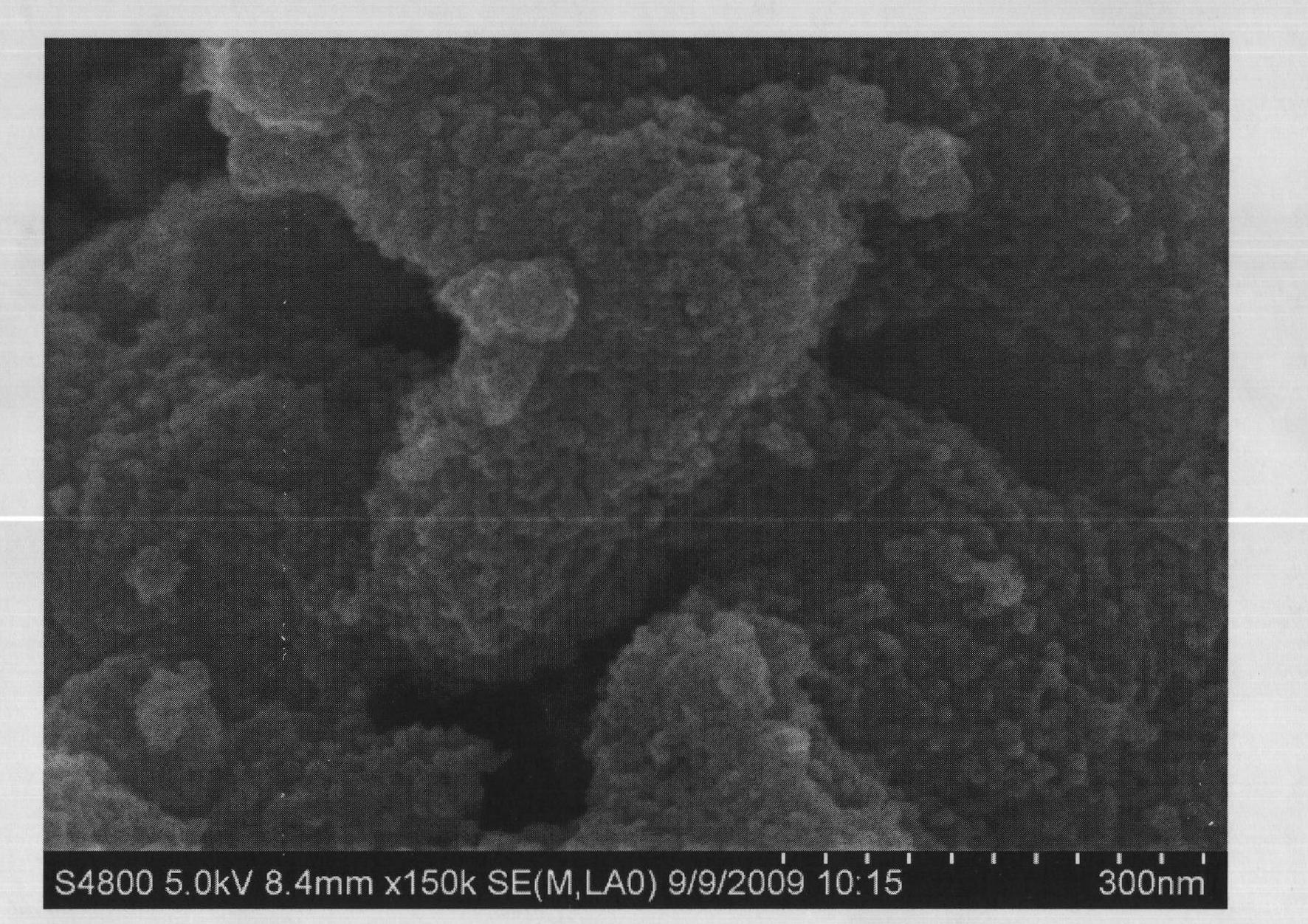

[0041] Observe the morphology of the above-mentioned prepared material with a JSM-5610LV type scanning electron microscope (SEM), as figure 1 As shown, it is obvious that the average particle size of the particles is about 40 nanometers, the particle size is small, the size is uniform, the size is basically the same, there is no obvious agglomeration phenomenon, and the shape is perfect.

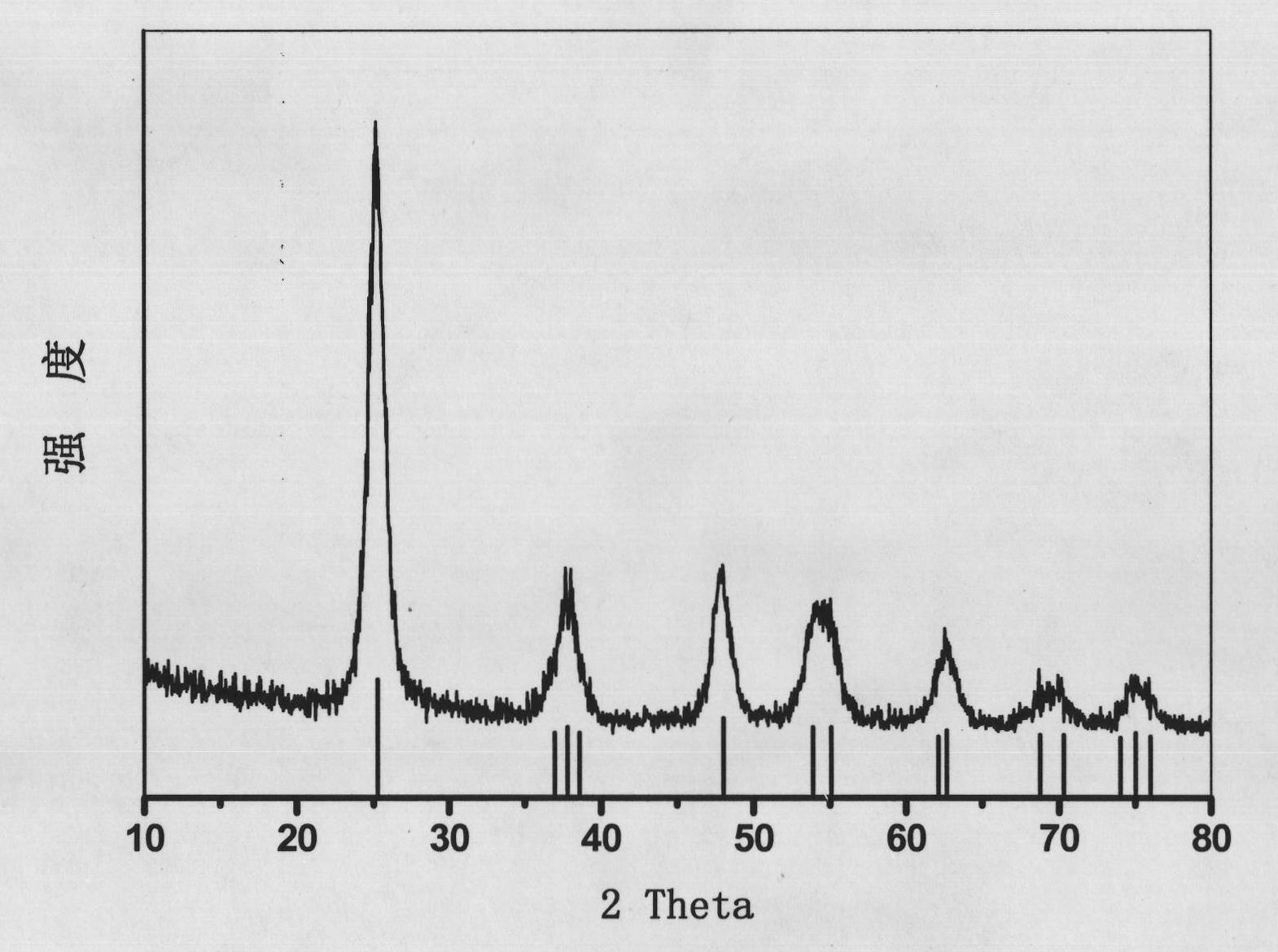

[0042] The phase and crystal structure of the product was analyzed by a Rigaku D / MAX-PC2200...

Embodiment 2

[0050] Preparation of titanium-containing precursors:

[0051] will 98% H 2 SO 4 50ml, dissolved in 2000ml of methanol (pH=2), stirred, added 35ml of aniline, gradually added 340ml of titanyl sulfate (greater than 98%) into the solution, and stirred thoroughly for 1h. 80g (NH 4 ) 2 S 2 o 8 Dissolve in 1500ml of deionized water, then slowly add it dropwise to the above solution, heat up to 70°C for 8 hours, filter, wash and dry repeatedly with deionized water and methanol.

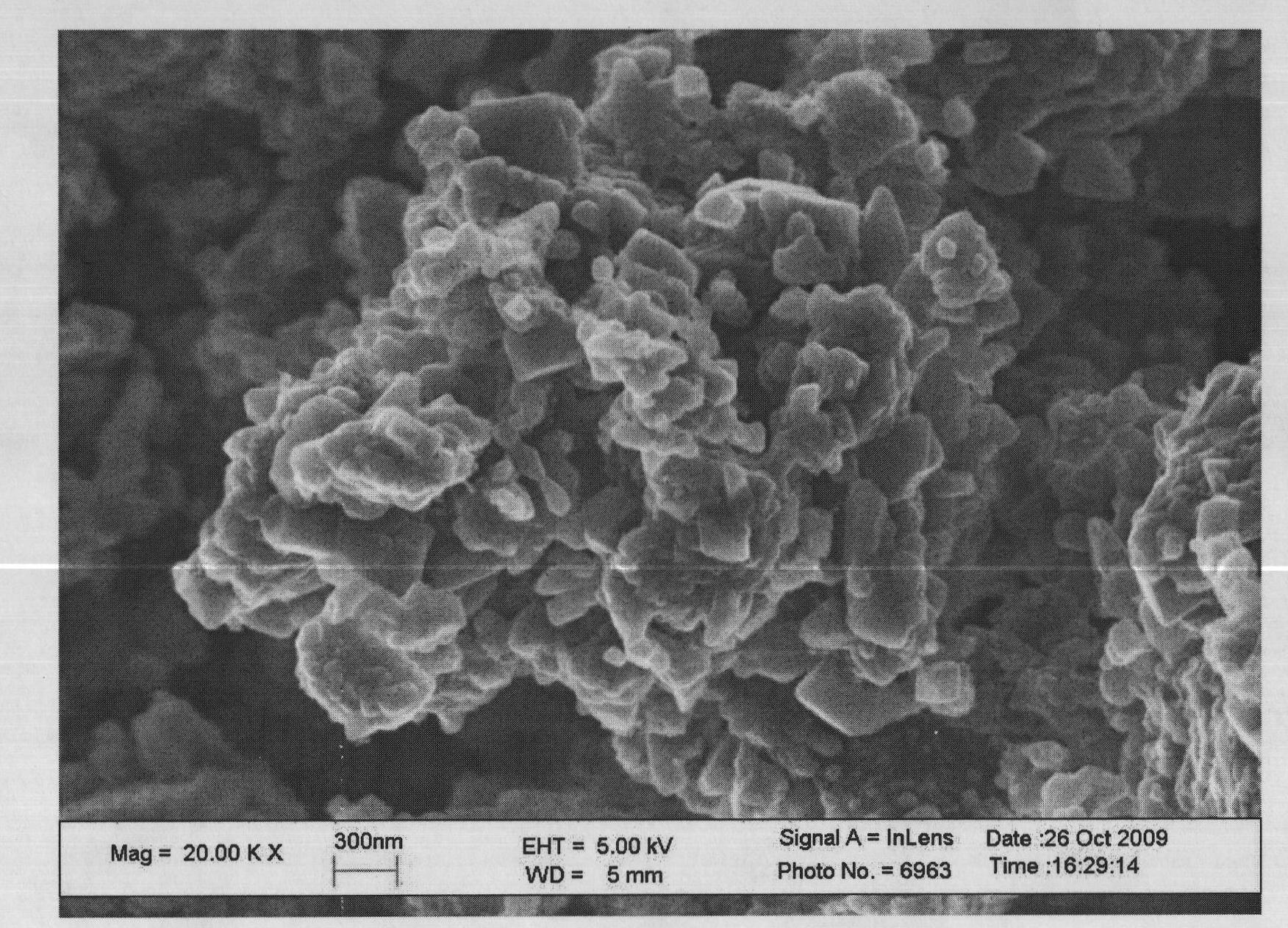

[0052] Using the same method as in Example 1 to observe the morphology of the sintered titanium-containing precursor prepared above, it can be seen that the average particle size is about 60 nanometers, the particle size is small, the size is uniform, the size is basically the same, and there is no obvious agglomeration phenomenon , the shape is perfect.

[0053] The same method as in Example 1 was used to prepare the negative electrode active material and the simulated battery.

[0054] The average...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com