Preparation method of low-density SiO2 aerogel/sponge composite material

A composite material and low-density technology, which is applied in the field of preparing low-density SiO2 aerogel/sponge composite materials, can solve the problems of poor shock absorption and sound insulation performance of sponge, and achieve high porosity, simple operation steps, and pore size structure. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

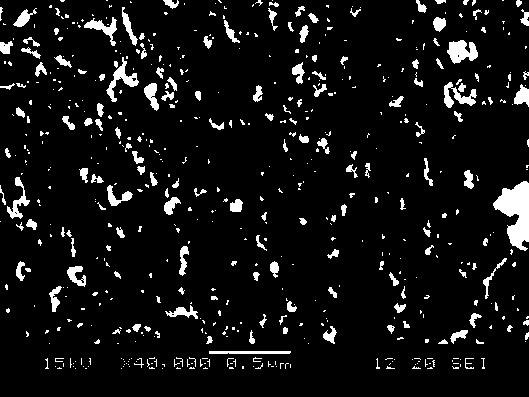

[0027] Heat a mixed solution of 22.3ml tetraethyl orthosilicate, 94ml absolute ethanol, 5.4ml deionized water, 5ml formamide and 0.3ml hydrochloric acid (1mol / L) as a catalyst at 50°C with constant stirring for 90min Finally, add ammonia water to adjust the pH value to about 6.5, and continue to stir for 5 minutes; pour the mixed solution into a mold with a sponge, let it stand at room temperature to obtain a wet gel, and then put the wet gel into a 60°C oven for use Anhydrous ethanol was used for solvent replacement, which was replaced every 12 hours for a total of 4 times. After the replacement was completed, the CO 2 Low-density SiO can be prepared by supercritical drying under ambient conditions 2 Airgel / sponge composites. prepared low-density SiO 2 The scanning electron microscope photos of the airgel / sponge composite samples are attached figure 1 shown, and the density of the composite material is 0.103g / cm 3 .

Embodiment 2

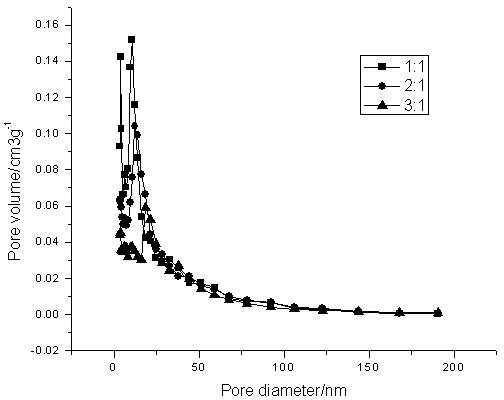

[0029] Heat the mixed solution of 67.2ml tetraethyl orthosilicate, 285ml absolute ethanol, 16ml deionized water, 15ml formamide and 0.9ml hydrochloric acid (1mol / L) as catalyst at 45°C and keep stirring, after 100min Add ammonia water to adjust the pH value to about 8, and continue to stir for 8 minutes; dilute the mixed solution with absolute ethanol, and dilute the absolute ethanol and silicon solution according to the volume ratio of 1:1, 2:1, and 3:1 respectively. The final mixed solutions were then poured into molds with sponges, and left to stand at room temperature to obtain wet gels. Then, the wet gels were placed in an oven at 55°C and replaced with absolute ethanol every 12 hours. Replacement 4 times, after replacement in CO 2 Low-density SiO can be prepared by supercritical drying under ambient conditions 2 Airgel / sponge composites. prepared low-density SiO 2 The pore size distribution of the airgel / sponge composite samples is shown in the attached figure 1 show...

Embodiment 3

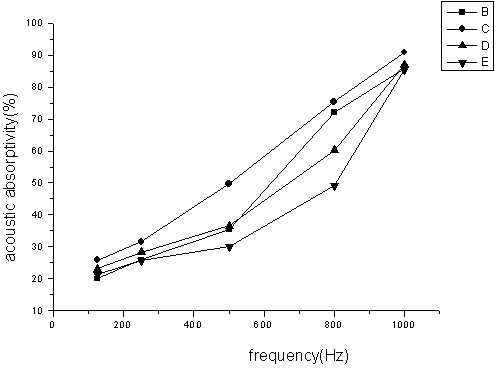

[0031] Heat a mixed solution of 67.2ml tetraethyl orthosilicate, 285ml absolute ethanol, 17ml deionized water, 15ml formamide and 1ml hydrochloric acid (1mol / L) as a catalyst at 55°C with constant stirring, add ammonia water after 85min Adjust the pH value to about 8, and continue to stir for 5 minutes; dilute the mixed solution with acetonitrile, and dilute the acetonitrile and silicon solutions according to the volume ratio of 1:1, 2:1, and 3:1, and then dilute the mixed solution. Pour them into molds with sponges respectively, stand at room temperature to obtain wet gels, and then put the wet gels into a 65°C oven for solvent replacement with absolute ethanol, once every 8 hours, a total of 7 replacements, replacement After completion in CO 2 Low-density SiO can be prepared by supercritical drying under ambient conditions 2 Airgel / sponge composites. prepared low-density SiO 2 The frequency curve of the sound absorption coefficient of the airgel / sponge composite sample is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com