Preparation method of silicon-based/graphene composite

A composite material and silicon-based material technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of environmental health and safety risks, high costs, complex procedures, etc., and achieve simple and controllable procedures, low costs, and significant potential economic effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

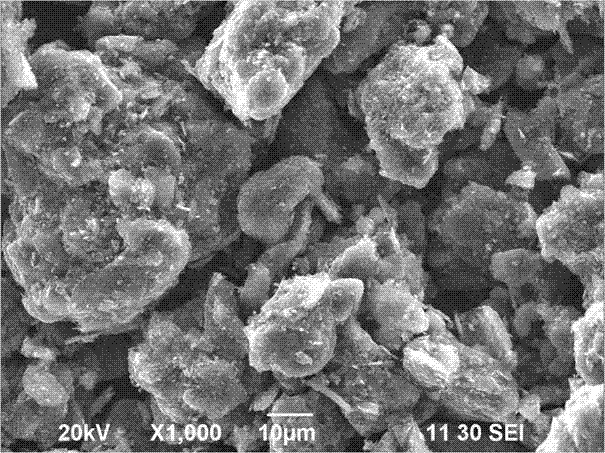

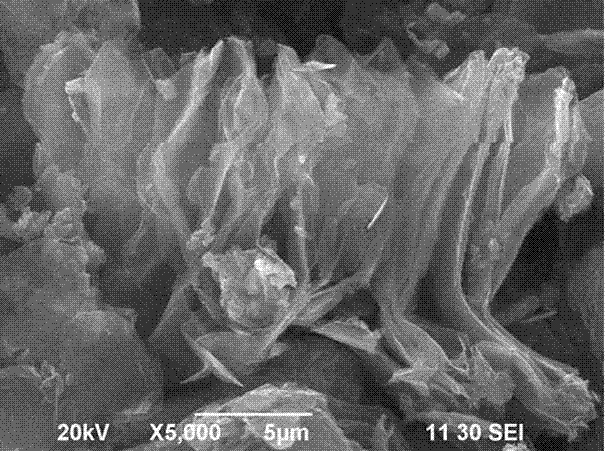

Image

Examples

Embodiment 1

[0037] A kind of preparation method of silicon base / graphene composite material provided by the present embodiment comprises the following steps:

[0038] Step 1, with silicon dioxide / natural graphite composite material (silicon dioxide uniformly adheres to the surface of natural graphite), conductive agent acetylene black, binder styrene-butadiene rubber and thickener sodium carboxymethyl cellulose ( The mass ratio of the four is 95:2:2:1) as the working electrode, and the lithium metal sheet as the counter electrode, with propylene carbonate (PC), diethyl carbonate (DEC) (both The mass ratio is 50:50) and lithium salt LiPF 6 The electrolyte and polyethylene separator were assembled into laminated cells in a dry room.

[0039] Step 2: Perform lithium intercalation treatment on the assembled laminated battery: charge and discharge the battery with a charge and discharge current of 1.2A, so that lithium ions and propylene carbonate (PC) are co-embedded in the interlayer of nat...

Embodiment 2

[0046] A kind of preparation method of silicon base / graphene composite material provided by the present embodiment comprises the following steps:

[0047] Step 1, with silica / artificial graphite composite material (silicon dioxide uniformly adheres to the surface of artificial graphite), conductive agent acetylene black, binder styrene-butadiene rubber and thickener sodium carboxymethyl cellulose ( The mass ratio of the four is 96:2:1:1) as the working electrode, containing lithium cobaltate, conductive agent acetylene black, and binder polyvinylidene fluoride (the mass ratio of the three is 96:2 :2) The pole piece is used as the counter electrode, and contains propylene carbonate (PC), dimethyl carbonate (DMC) (the mass ratio of the two is 70:30) and lithium salt LiPF 6 The electrolyte and polyethylene separator were assembled into laminated cells in a dry room.

[0048] Step 2: Perform lithium intercalation treatment on the assembled laminated battery: charge and discharge ...

Embodiment 3

[0053] A kind of preparation method of silicon base / graphene composite material provided by the present embodiment comprises the following steps:

[0054] Step 1, with silicon / mesocarbon microsphere composite material (silicon uniformly adheres to the surface of mesocarbon microspheres), conductive agent conductive graphite, binder polyvinylidene fluoride and thickener carboxymethyl fiber The pole piece of plain sodium (the mass ratio of the four is 94:2:2:2 in turn) is used as the working electrode, containing lithium manganate, conductive graphite as a conductive agent, and polyvinylidene fluoride as a binder (the mass ratio of the three is in turn: 94:3:3) as the counter electrode, with propylene carbonate (PC), ethyl methyl carbonate (EMC) (the mass ratio of the two is 60:40) and lithium salt LiPF 6 The electrolyte and polyethylene separator were assembled into a soft-pack battery in a dry room.

[0055] Step 2: Perform lithium intercalation treatment on the assembled fle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com