Method for preparing lithium iron phosphate/carbon composite material by thickener doping modification

A carbon composite material, lithium iron phosphate technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of lack of cobalt resources, excessive grain growth of product particles, low purity, etc., to achieve large-scale industrial production, The effect of reduced electrode polarization and controllable process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

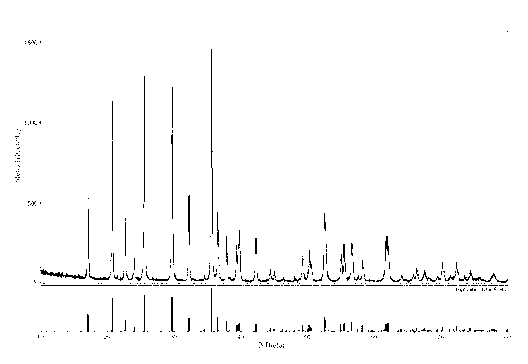

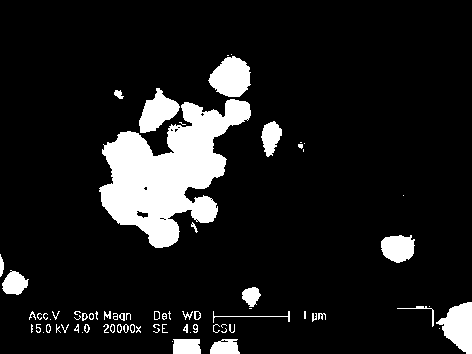

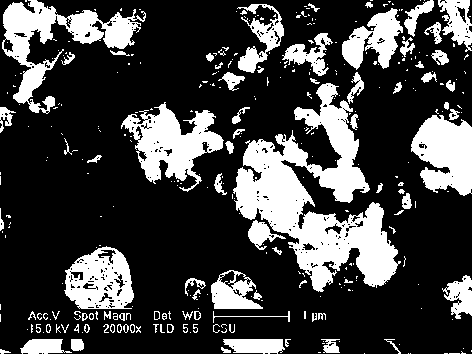

Image

Examples

Embodiment 1

[0024] Weigh 1 mol FeC 2 o 4 2H 2 O, 1 mol NH 4 h 2 PO 4 and 0.4975 mol Li 2 CO 3 , and adding sucrose as a carbon source, ball milling and mixing for 6 hours by ball milling, then putting it into an argon-protected tube furnace, and pretreating at 600°C for 5 hours to obtain the precursor.

[0025] Weigh 0.005mol sodium carboxymethylcellulose, and completely dissolve it in water to form an aqueous solution. Stir the sodium carboxymethyl cellulose aqueous solution with a certain solubility at a high speed under a mechanical mixer, add sucrose therein, and after it dissolves, add the precursor material, and continue stirring at a high speed for a period of time to obtain a uniformly stirred The mixture is dried in an oven. Finally, in an argon-protected tube furnace, heat treatment at 700 °C for 10 h at high temperature to obtain the product Li 0.995 Na 0.005 FePO 4 / C.

[0026] In the above preparation method, the lithium iron phosphate / carbon composite material is...

Embodiment 2

[0029] Weigh 1 mol Fe 2 o 3 , 1 mol H 3 PO 4 and 0.99 mol LiOH, and glucose was added as a carbon source. After ball milling and mixing for 3 hours, it was placed in a nitrogen-protected tube furnace and pretreated at 350 ° C for 3 hours to obtain the precursor.

[0030] Weigh 0.01mol of sodium alginate and dissolve it completely in water to form an aqueous solution. Stir the prepared sodium alginate aqueous solution at high speed under a mechanical stirrer, add glucose to it, and after it dissolves, add the precursor material, continue stirring at high speed for a period of time, and place the uniformly stirred mixture in an oven for drying Dry. Finally, in a nitrogen-protected tube furnace, heat treatment at 600 °C for 6 hours at high temperature to obtain the product Li 0.99 Na 0.01 FePO 4 / C.

[0031] In the above preparation method, the lithium iron phosphate / carbon composite material is prepared by doping and modifying the thickener. The final product adopts a S...

Embodiment 3

[0033] Weigh 1 mol Fe(NO 3 ) 3 9H 2 O, 1 mol (NH 4 ) 3 PO 4 and 0.98 mol LiCH 3 COO, and citric acid was added as a carbon source, ball milled and mixed for 10 h by ball milling, then placed in a nitrogen-protected tube furnace, and pretreated at 500°C for 10 h to obtain a precursor.

[0034] Weigh 0.02mol potassium alginate and dissolve it completely in water to form an aqueous solution. Stir the prepared sodium alginate aqueous solution at high speed under a mechanical mixer, add citric acid to it, and after it dissolves, add the precursor material, continue stirring at high speed for a period of time, and place the uniformly stirred mixture in an oven for drying. Finally, in an argon-protected tube furnace, heat treatment at 600°C for 20 hours at high temperature to obtain the product Li 0.98 K 0.02 FePO 4 / C.

[0035] In the above preparation method, the lithium iron phosphate / carbon composite material is prepared by doping and modifying the thickener. The fina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com