Oil slick collection method

A technology for oil slicks and oil slicks on the water surface, which is applied in general water supply conservation, cleaning of open water surfaces, water conservancy projects, etc., can solve problems such as incomplete recovery, rising oil slick recovery costs, and difficult operation, so as to reduce recovery costs, The effect of reducing post-processing procedures and efficient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

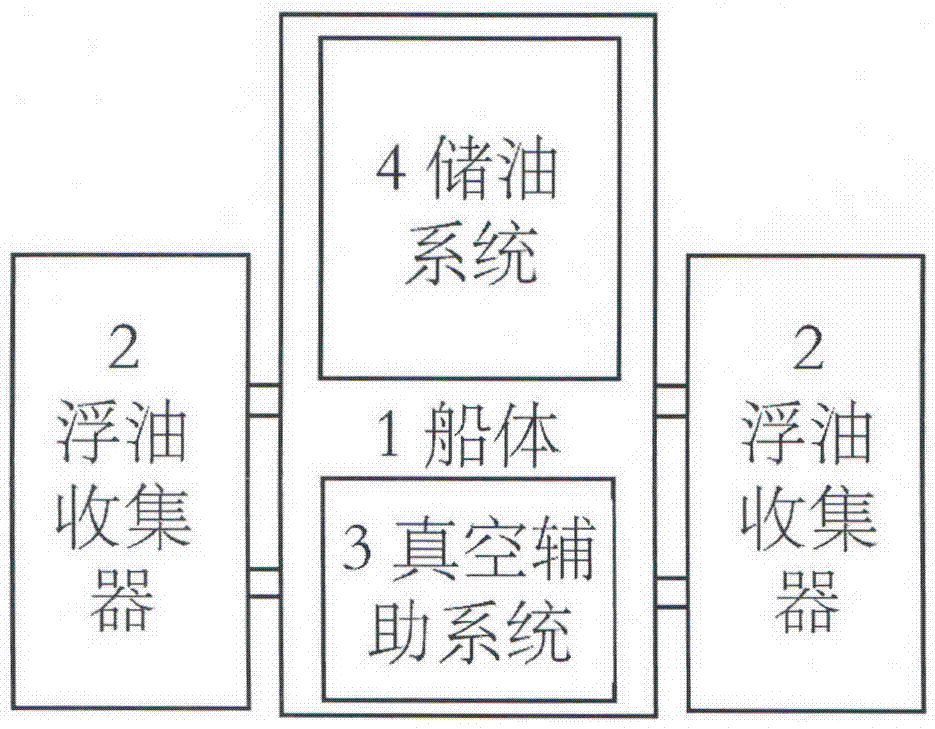

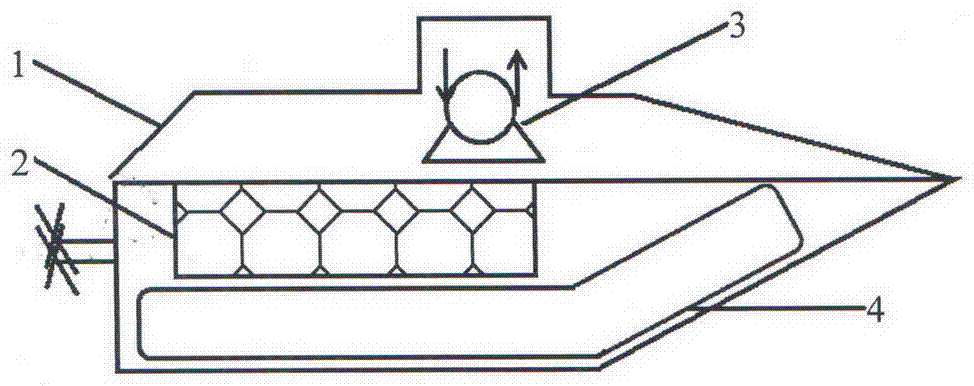

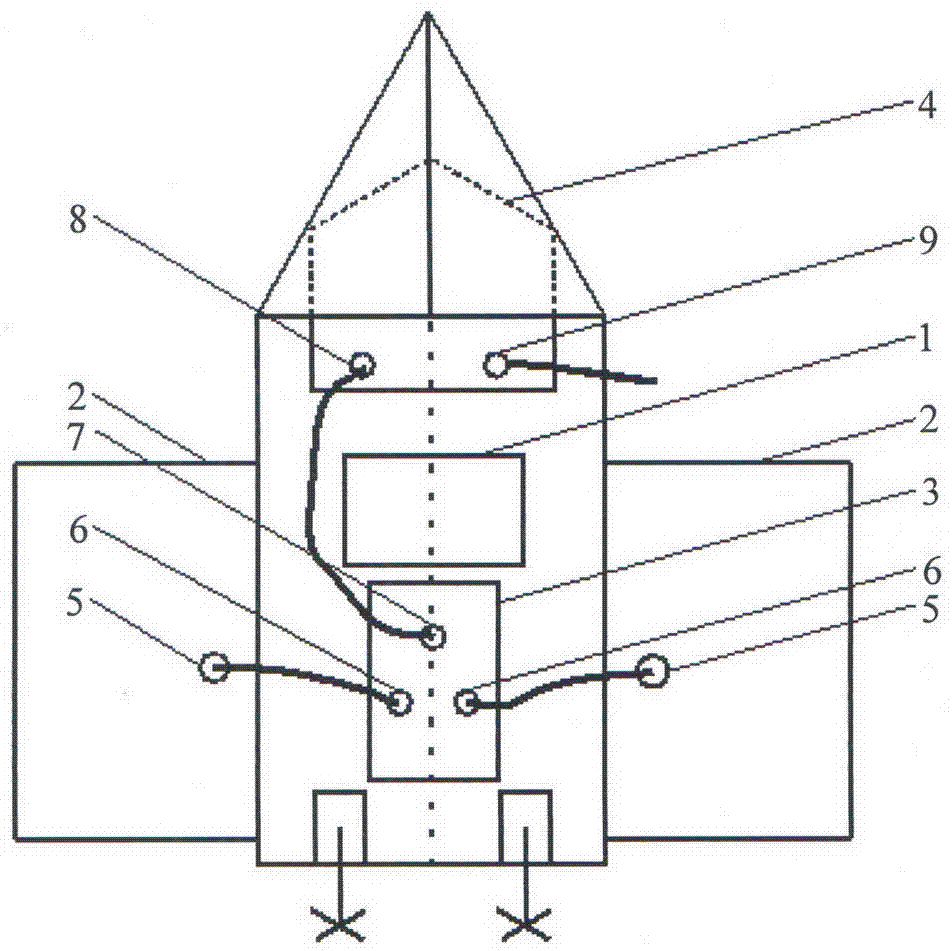

[0023] The surface oil slick collection device is composed of four parts: the hull, the oil slick collector, the vacuum auxiliary system and the oil storage system; the oil slick collector 2 is fixed on both sides of the hull 1, and the mechanical vacuum auxiliary system is fixed at the rear end of the hull 1 3. The oil storage system 4 is fixed at the front of the hull 1, the mechanical vacuum auxiliary system 3 is connected to the outlet pipe 5 of the floating oil collector 2 through the oil inlet pipe 6, and the outlet pipe 7 of the mechanical vacuum auxiliary system 3 is connected to the storage The oil inlet pipeline 8 of the oil system 4 is connected, the outlet pipeline 9 of the oil storage system 4 is connected with an external container, and a porous oil-water separation material with superhydrophobic and superoleophilic properties is arranged in the oil floating collector 2, and the specific operation is as follows conduct:

[0024] a. The surface oil slick collectin...

Embodiment 2

[0027] The floating oil collecting device on the water surface is carried out according to embodiment 1, and the specific operation is carried out according to the following steps:

[0028] a. The surface oil slick collecting device fixed on the hull 1 sails on the water surface through remote control. When encountering a gasoline leakage area, the super-hydrophobic and super-oleophilic porous melamine sponge in the oil slick collector 2 will collect the oil slick on the water surface fast adsorption;

[0029] b, the adsorbed gasoline is extracted through the outlet pipeline 5 of the oil slick collector 2 through the mechanical vacuum auxiliary system 3, and the oil recovered in the oil slick collector 2 is extracted, and then enters the oil inlet pipeline 6 of the mechanical vacuum auxiliary system 3, and then The outlet pipe 7 of the mechanical vacuum auxiliary system 3 is pumped into the oil inlet pipe 8 of the oil storage system 4. When the capacity of the oil storage syst...

Embodiment 3

[0031] The floating oil collecting device on the water surface is carried out according to embodiment 1, and the specific operation is carried out according to the following steps:

[0032] a. The surface oil slick collecting device fixed on the hull 1 sails on the water surface through remote control. When encountering an area with diesel oil leakage, the super-hydrophobic and super-oleophilic porous nylon fiber in the oil slick collector 2 will quickly absorb the oil slick on the water surface carry out adsorption;

[0033] b. The adsorbed diesel oil is extracted through the outlet pipeline 5 of the oil slick collector 2 through the mechanical vacuum auxiliary system 3 to extract the recovered diesel oil in the oil slick collector 2, and enter the oil inlet pipeline 6 of the mechanical vacuum auxiliary system 3, and then The outlet pipe 7 of the mechanical vacuum auxiliary system 3 is pumped into the oil inlet pipe 8 of the oil storage system 4. When the capacity of the oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com