Automatic scum collecting system

An automatic collection and scum technology, which is applied in waterway system, grease/oily substance/floating matter removal device, water/sludge/sewage treatment, etc., can solve the problems of waste of manpower and material resources, being washed away, and high operating cost. Achieve the effect of reducing construction cost and operating cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

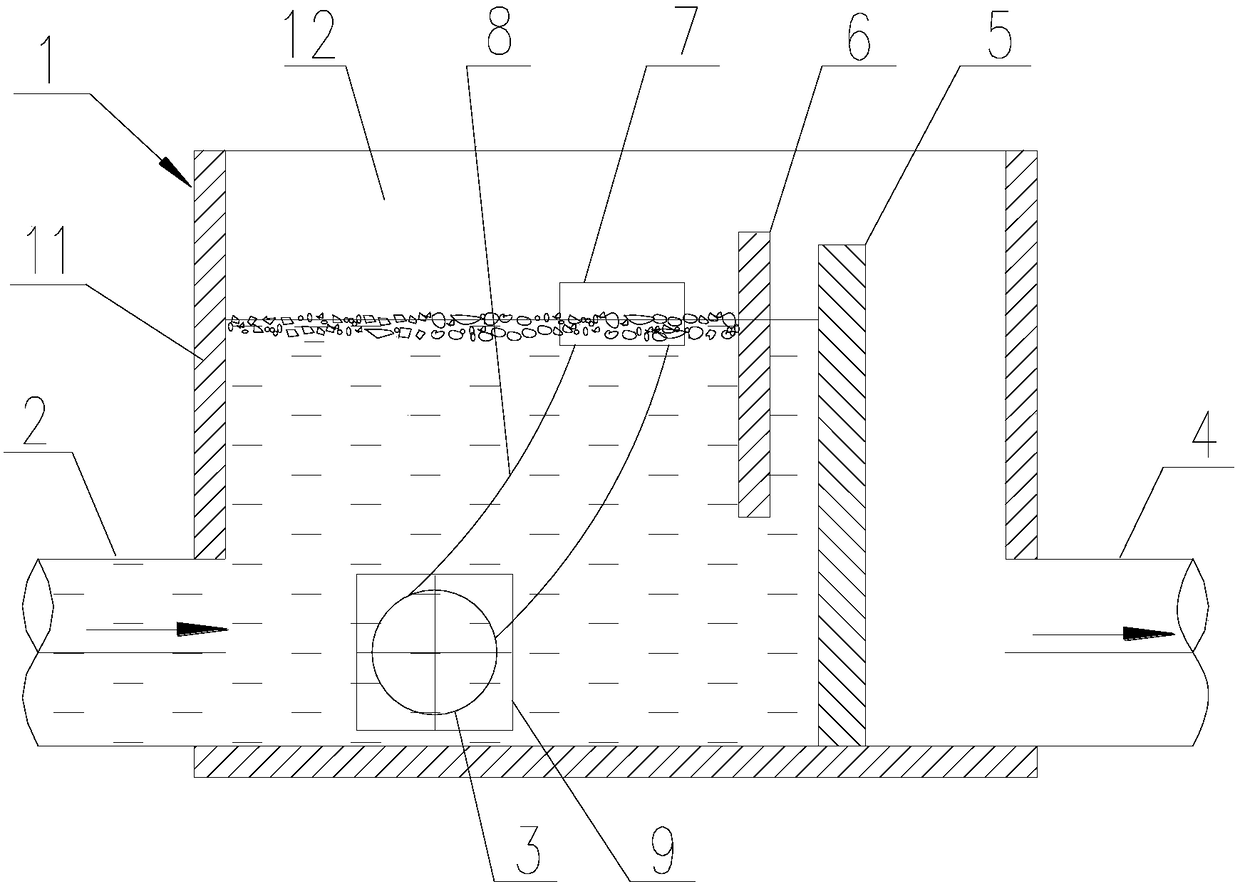

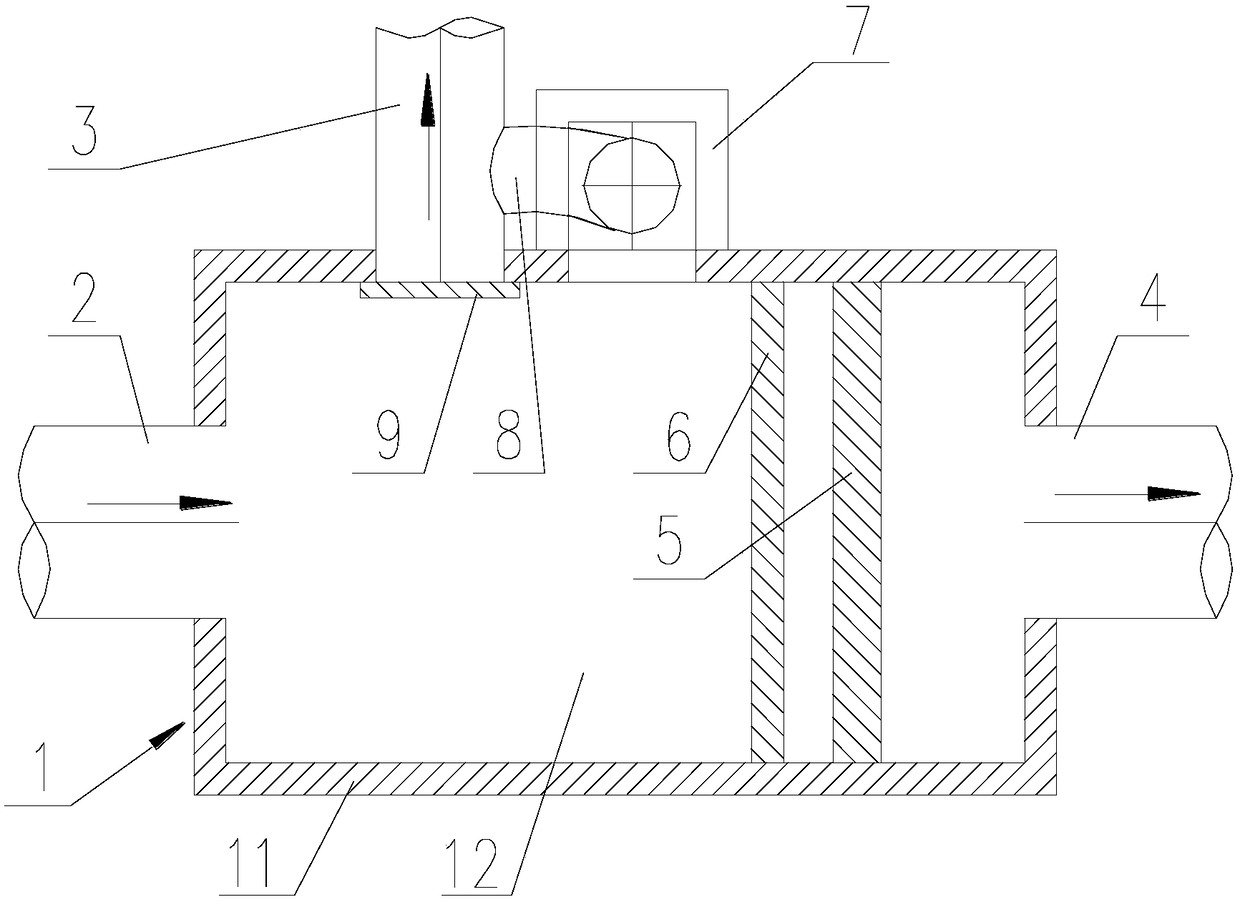

[0030] see figure 1 with figure 2 As shown, on the basis of the above-mentioned technical solution, the first hydraulic switch is a retractable weir gate 5 of the discharge outlet. The height that the weir door 5 of the drain outlet protrudes is higher than the highest drainage position of the drain outlet.

[0031] In practical applications, the first hydraulic switch can also be a gate or a gate valve, and the gate or gate valve is arranged at the drain.

Embodiment 2

[0033] The diversion well wall 11 is also provided with a sewage outlet, the sewage outlet communicates with the inner cavity 12 of the diversion well, and the sewage outlet communicates with the inner cavity 12 of the diversion well and the sewage treatment plant through the sewage interceptor 3, and the minimum water inlet position of the scum collection inlet is at a level of The water outlet of the scum collecting pipe 8 is connected to the sewage intercepting pipe 3 at a level higher than the highest water inlet position of the sewage outlet. The system of the present invention also includes a second hydraulic switch for controlling the water output of the sewage outlet. The second hydraulic switch is located in front of the connection between the water outlet pipe mouth and the sewage intercepting pipe 3 . Specifically, the second hydraulic switch is the sewage outlet gate 9, and the sewage outlet gate 9 is arranged at the sewage outlet.

[0034] In practical applicatio...

Embodiment 3

[0036] The baffle plate 6 is a fixed baffle plate, the two sides of the fixed baffle plate are fixedly connected with the shunt well wall 11, the horizontal height of the upper edge of the fixed baffle plate is higher than the horizontal height of the highest water inlet position of the scum collection inlet, and the lower edge of the fixed baffle plate is The water level in the diversion well 1 controlled by the hydraulic switch is always higher than the level of the lower edge of the fixed baffle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com