Electrostatic spinning continuous collection device

An electrospinning and receiving device technology, which is applied in the field of continuous collection devices for electrospinning, can solve the problems of uncontrollable fiber shape and thickness, prolonging coagulation time, and reducing coagulation rate, so as to reduce coagulation time and discharge of waste liquid. , Improve solidification efficiency, improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0032] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

[0033] The invention discloses a method for continuous collection of electrospinning, which is to atomize coagulation bath solution to carry out continuous collection of electrospinning.

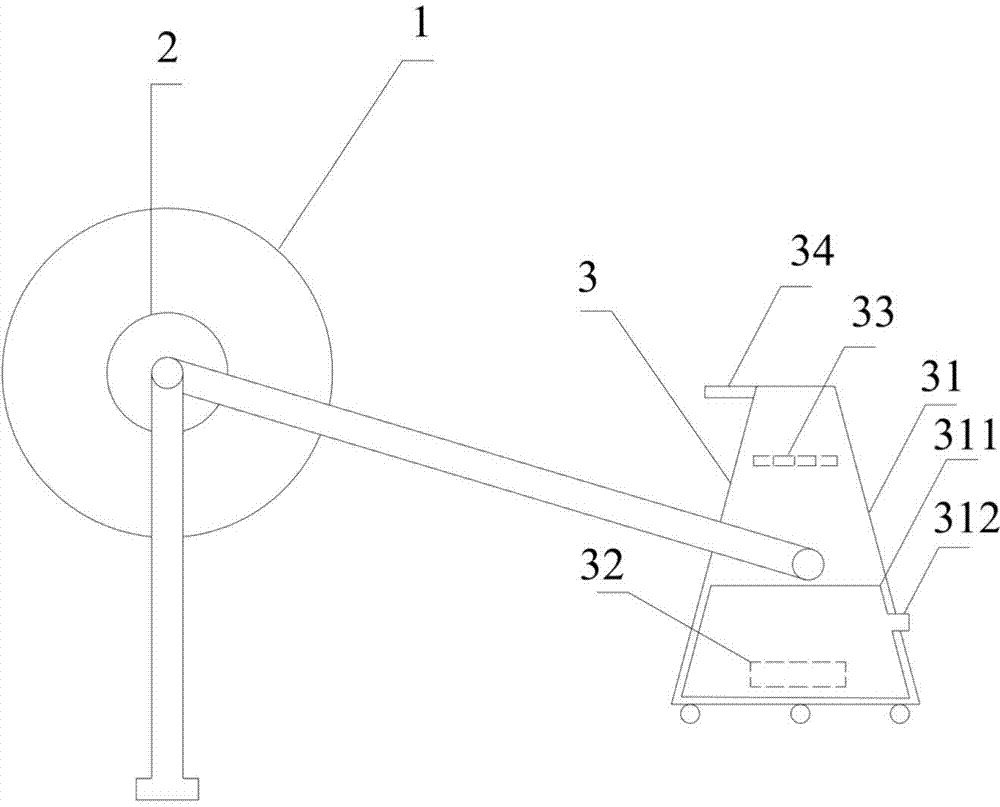

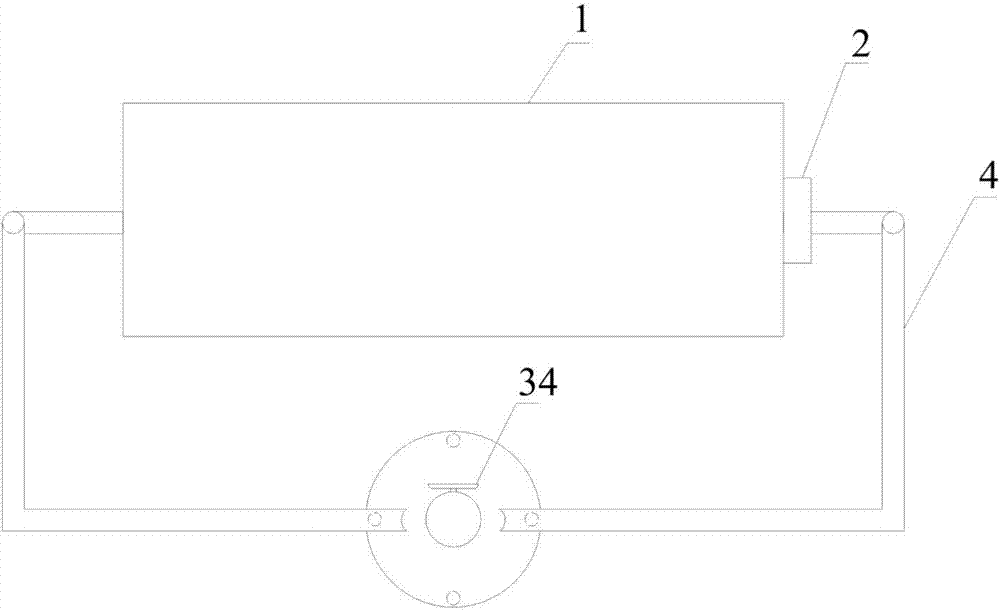

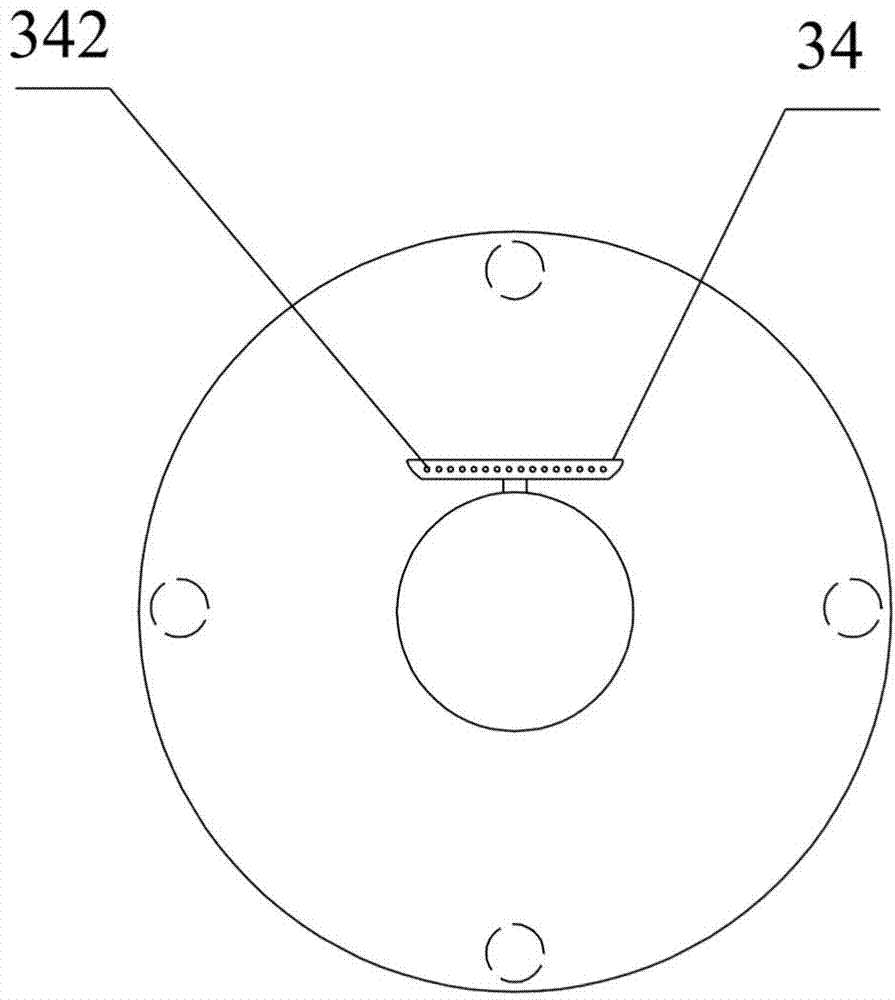

[0034] Figure 1-2 According to an implementation form of the present invention, a device for continuous collection of electrospinning is provided, including:

[0035] The receiving device 1 is cylindrical, and the two ends of the receiving device 1 are respectively fixed horizontally by brackets;

[0036] Motor 2, which is connected to the receiving device 1 and drives the receiving device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com