Method for synthesizing guaiacol

A technology of guaiacol and catechol, applied in chemical instruments and methods, dehydration of hydroxyl-containing compounds to prepare ethers, metal/metal oxide/metal hydroxide catalysts, etc., can solve large environmental pollution and useless substances , Vanillin quality impact and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The catalyst of the present invention is ammonium metatungstate supported on silica, prepared by traditional impregnation method, a certain amount of ammonium metatungstate aqueous solution (or other active component aqueous solution) is impregnated in the formed 40-60 mesh commercial carbon dioxide On silicon particles, dry, and bake at 533-733K for 3 hours. The content of tungsten is 7.9% of the total mass of the catalyst (based on tungsten content).

Embodiment 2

[0033] The catalyst of the invention is used for the gas-solid phase alkylation reaction of catechol and methanol to synthesize guaiacol.

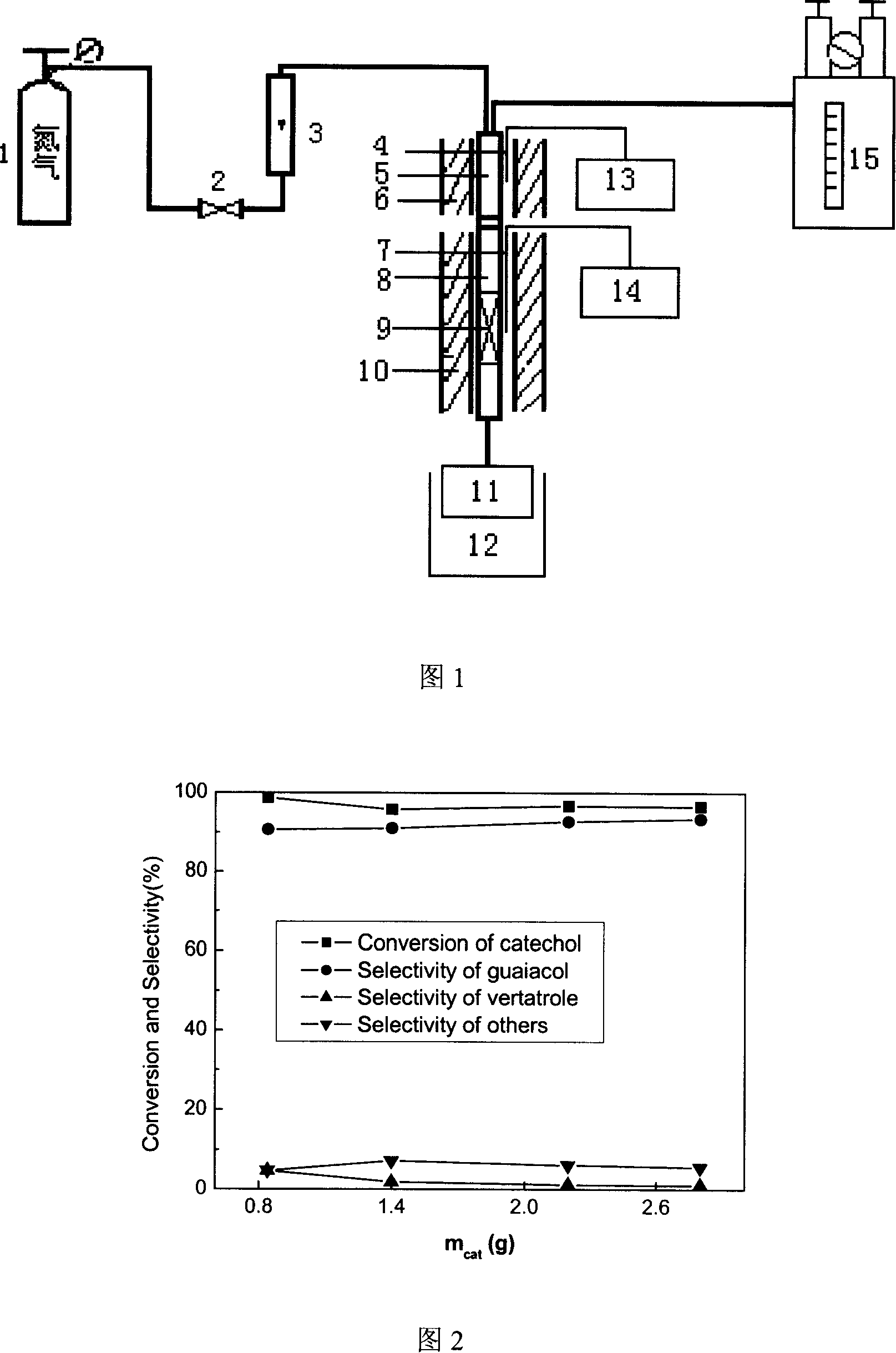

[0034] The device used in the reaction is shown in Figure 1, among the figure 1 nitrogen cylinder, 2 steady flow valves, 3 rotameters, 4 and 7 thermocouples, 5 and 8 reaction tubes, 6 and 10 heating furnaces, 9 catalyst beds, 11 Collection bottles, 12 cold traps, 13 and 14 programmed temperature controllers, 15 SY-04 sampling pumps.

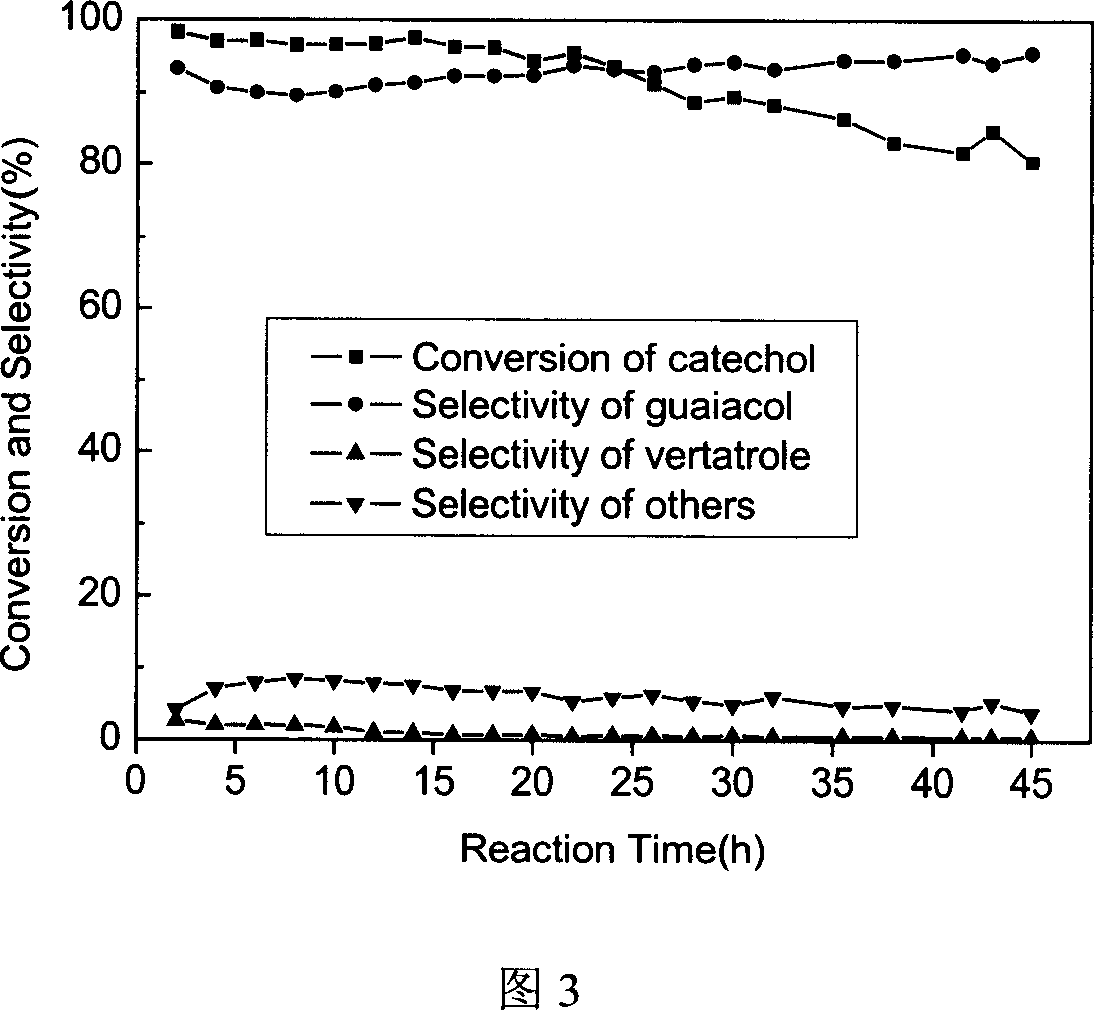

[0035] During the reaction, the reaction temperature is 533K, the flow rate is 0.5mL / h, the catalyst is 1.4g, and the ratio of catechol to methanol is 1 / 5 (mol).

Embodiment 3

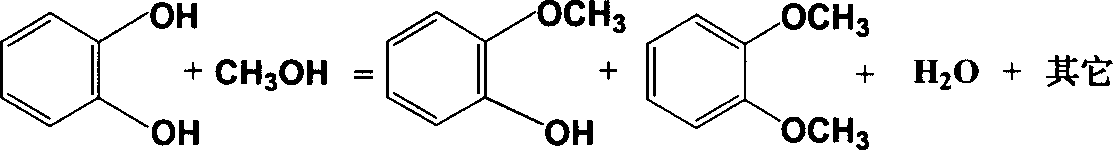

[0045] The lifetime of the catalyst was investigated as described in Example 2.

[0046] Test result analysis example 1

[0047] Table 1 has listed comparative example 1-6 and the catalytic activity comparison that the prepared catalyst of embodiment 1 carries out by embodiment 2, visible C, SiO 2 and TiO 2 When used as a carrier, the activity is higher, among which SiO 2 The activity is the best when used as a carrier.

[0048] Table 1 Reaction performance of ammonium metatungstate supported on different carriers

[0049]

[0050] m cat =1.4g, catechol / methanol=1 / 5 (mol), flow velocity=0.5mL / h, reaction temperature=533K, reaction time=3-4h; W content=7.9wt.%

[0051] Test result analysis example 2

[0052] Table 2 lists the catalytic activity comparisons of the catalysts prepared in Comparative Examples 7-10 and Example 1 according to Example 2. It can be seen that the activity is the best when the tungsten loading is 7.9%.

[0053] Table 2 SiO 2 Reaction pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com