Absorbent removing thiol from acidic airflow and method therefor

An absorbent and air flow technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of large investment, expensive regeneration and high total consumption index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

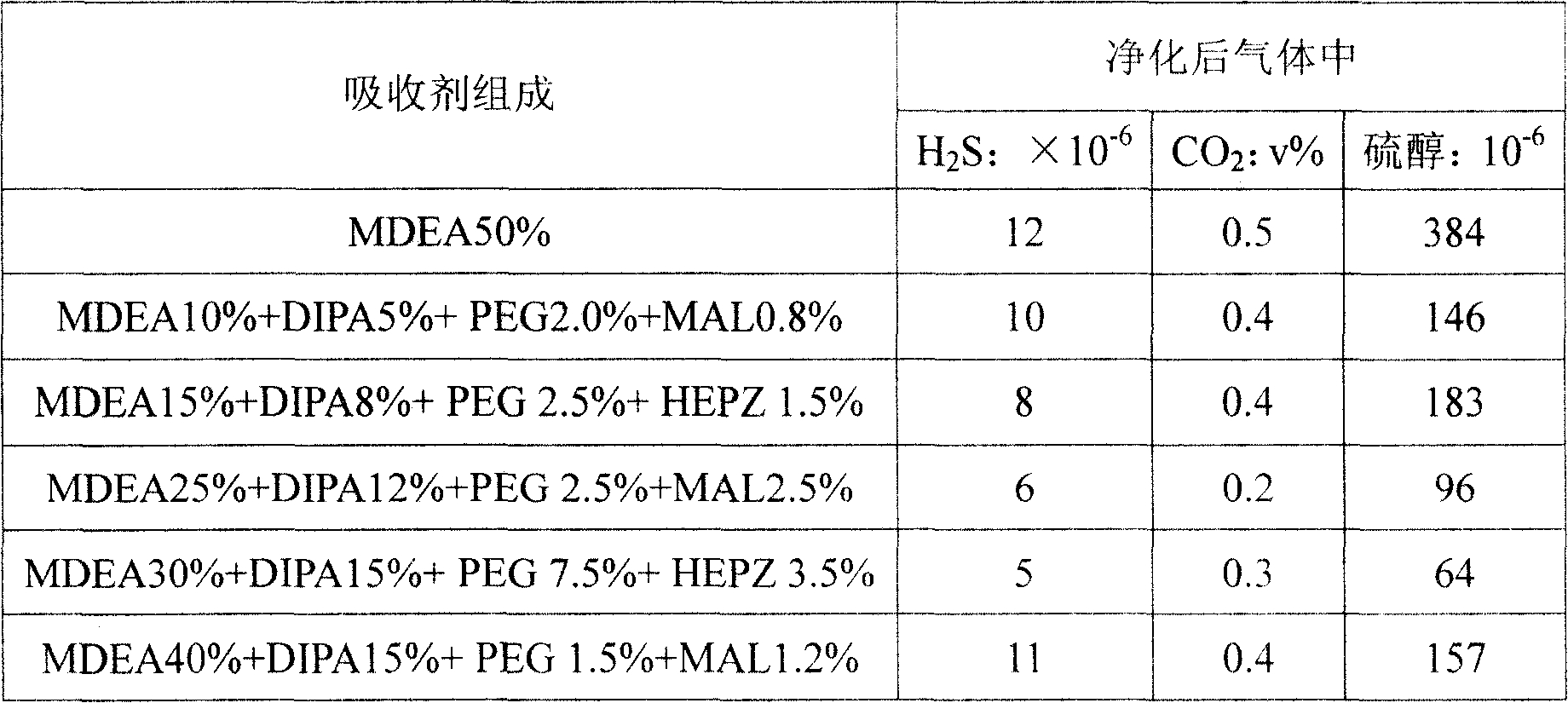

[0022] The performance of specific absorbents is measured directly on a test rig. The inner diameter of the absorption tower used in the test is 20mm, with φ3×3 stainless steel θ rings inside, the inner diameter of the regeneration tower is 50mm, with φ6×6×1 porcelain Raschig rings inside, and a reboiler is installed at the bottom of the regeneration tower.

[0023] Prepared raw material gas (containing H 2 S 5%, CO 2 13%, methyl mercaptan 246×10 -6 , ethanethiol 132×10 -6 , 1-propanethiol 46×10 -6 , 2-propanethiol 38×10 -6 ) into the bottom of the absorption tower and countercurrently contact with the solution entering from the top of the tower, the acid gas in the gas is absorbed, and the purified gas comes out from the top of the tower and enters the gas-liquid separator to recover the entrained liquid droplets and then empties.

[0024] The rich liquid that has absorbed the acid gas is drawn from the bottom of the absorption tower to the top of the regeneration tower,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com