Method for preparing fluorocarbon-modified polyacrylamide by using soap-free emulsion method

A technology for polyacrylamide and soap-free emulsion polymerization, which is applied in the field of water-soluble polymer synthesis, and can solve problems such as adverse effects of the copolymerization process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

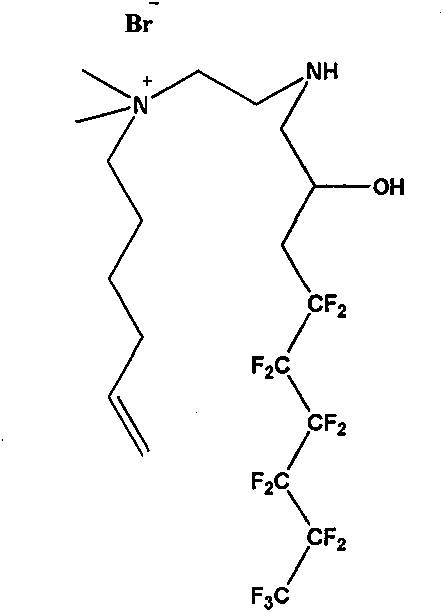

[0059] Embodiment 1. Preparation of fluorocarbon / hydrocarbon mixed type cationic surface-active monomer

[0060] (1) Preparation of compound I

[0061] Weigh 0.88g (10mmol) of N, N-dimethylethylenediamine and dissolve it in 15ml of DMF, transfer to a condenser tube (connected with CaCl 2 Drying tube), nitrogen tube, and constant pressure dropping funnel in a 50ml three-neck round bottom flask, then put it into a constant temperature water bath at 25°C, add the rotor, start stirring, and pass through nitrogen to remove oxygen for 30min. Weigh 2.62g (12mmol) of Boc anhydride and dissolve in 10ml of DMF, then transfer to a 25ml constant pressure dropping funnel. Open the cock, drop the Boc anhydride dissolved in DMF into the three-neck flask drop by drop, after 0.5h, remove the constant pressure dropping funnel. After the mixture was reacted for 1 h, 2.45 g (15 mmol) of 6-bromo-1-hexene was dissolved in 5 ml of DMF and transferred to a 10 ml constant pressure dropping funnel. ...

Embodiment 2

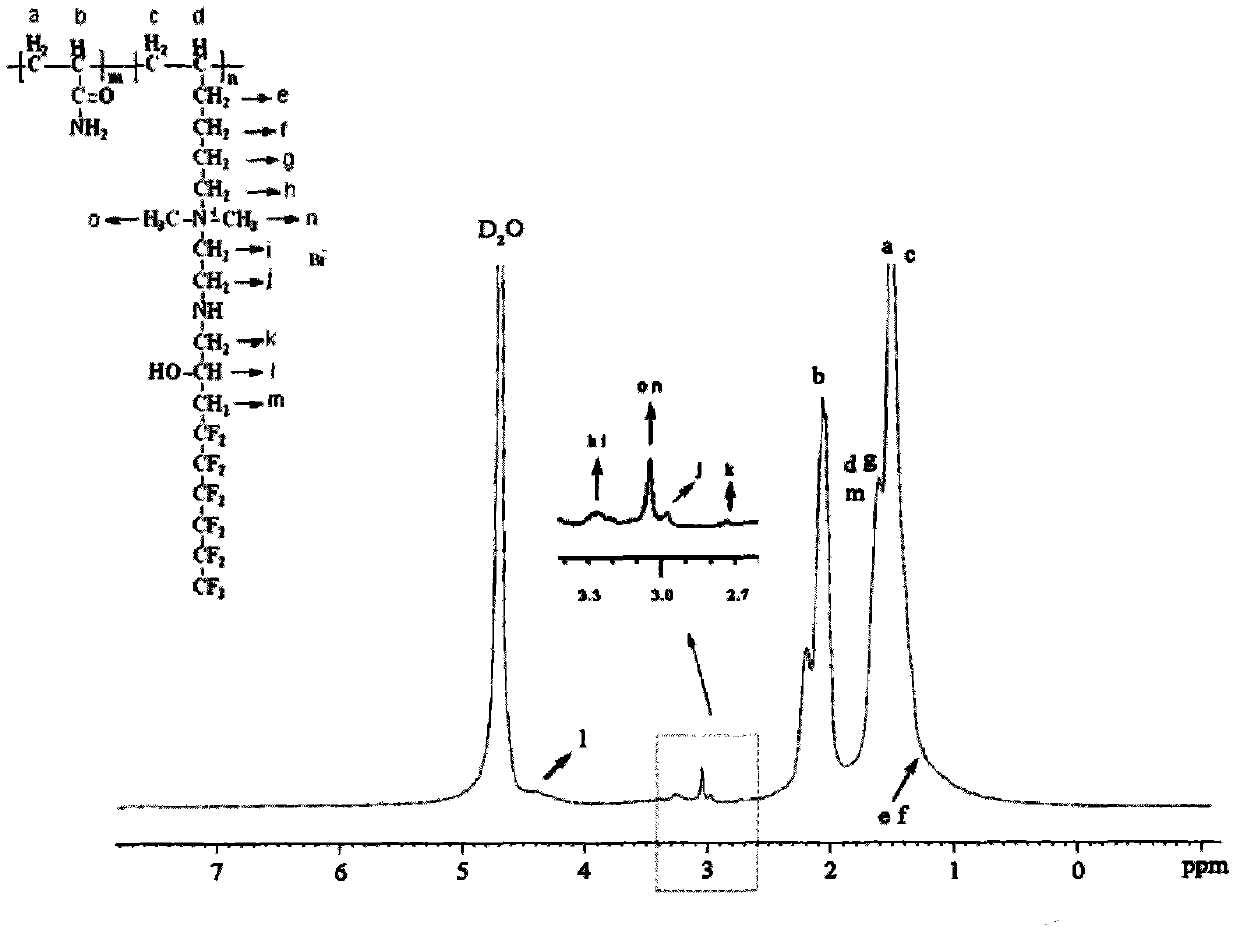

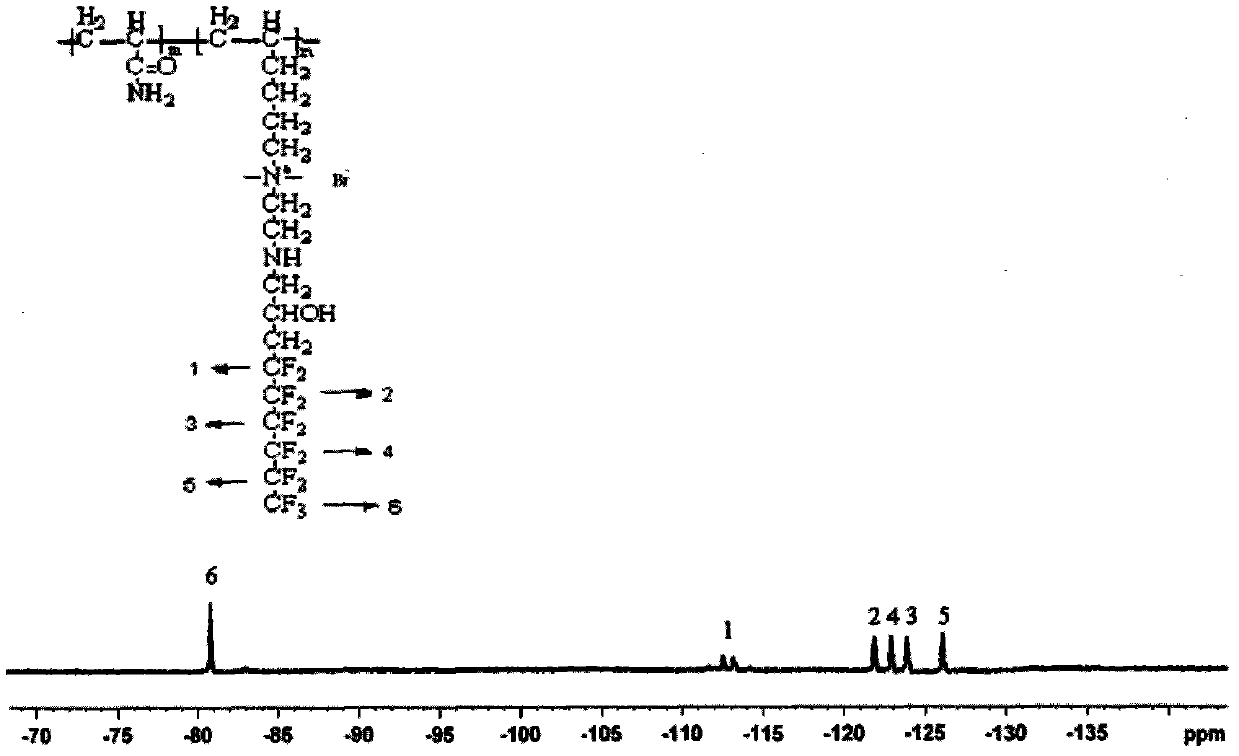

[0068] Embodiment 2. Preparation of fluorocarbon modified polyacrylamide

[0069] (1) Transfer 80ml of deionized water into a 250ml four-necked round-bottom flask equipped with a mechanical stirring rod, a spherical condenser, a nitrogen vent tube, and a thermometer, and weigh 7.0582g (99.3mmol) of acrylamide into the four-necked flask , into N 2 , stirred at room temperature for 1h.

[0070] (2) Weigh 0.4391g (0.7mmol) of fluorocarbon / hydrocarbon mixed cationic surfactant monomer, dissolve it in 10ml of deionized water, and after fully dissolving, it becomes a yellow clear and transparent solution, and transfer it to a four-necked bottle after standing for 10min In the process, rinse the remaining liquid and foam repeatedly with 10ml of deionized water and transfer them into the reaction system together. The temperature of the reaction system was raised to 65°C, and the stirring was continued, and the N 2 Protection, keep 30min.

[0071] (3) Weigh 0.0541g (2mmol / L) of potas...

Embodiment 3

[0074] Embodiment 3. Preparation of fluorocarbon modified polyacrylamide

[0075] As described in Example 2, the difference is that the monomer feed ratio is changed to 0.2509 g of fluorocarbon / hydrocarbon mixed cationic surface active monomer and 7.0795 g of acrylamide to obtain 7.0880 g of light yellow powder of fluorocarbon modified polyacrylamide , the yield was 96.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com