Preparation method of silver nanowires

A technology of silver nanowires and silver salts, which is applied in the field of preparation of nanomaterials and can solve problems such as slow reaction and long preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

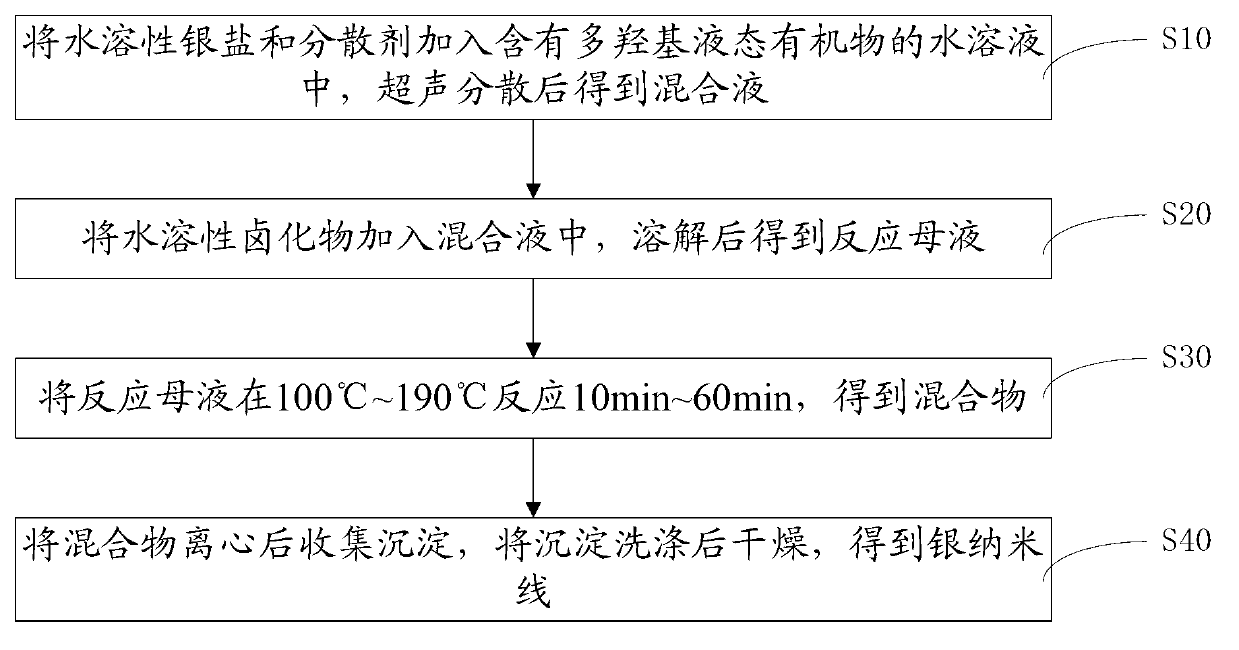

[0030] Such as figure 1 Shown, the preparation method of the silver nanowire of one embodiment, comprises the following steps:

[0031] Step S10, adding the water-soluble silver salt and the dispersant into the aqueous solution containing the polyhydroxy liquid organic matter, and ultrasonically dispersing to obtain a mixed solution.

[0032] The water-soluble silver salt is at least one selected from silver nitrate and silver acetate. When the water-soluble silver salt is silver nitrate, silver nitrate has better solubility in most solvents such as water and ethanol.

[0033] The molar ratio of water-soluble silver salt and dispersant is 1:1~1:10. When the mol ratio of water-soluble silver salt and dispersing agent is 1:5, the silver nanowire prepared is better, and this is because the amount of dispersing agent is too much, easily generates granular silver, and the amount of dispersing agent is insufficient, and It is not conducive to the growth of auxiliary nano-silver w...

Embodiment 1

[0058] In a 200W ultrasonic water bath, mix 6.8g of silver nitrate and 22.2g of polyvinylpyrrolidone K30 and add it into an aqueous solution containing 100mL of ethylene glycol (the volumes of ethylene glycol and deionized water are 50mL and 50mL respectively), and after uniform dispersion and dissolution A clear solution was obtained.

[0059] 5.8 mg of sodium chloride was added to the above clear solution, and after dissolving, a clear reaction mother liquor was obtained.

[0060] The reaction mother liquor was transferred to a self-pressurized reactor, and the self-pressurized reactor was placed in an oil bath at 120° C., and the mixture was obtained after reacting for 20 minutes.

[0061] The above mixture was cooled to room temperature, and the precipitate was collected after centrifugation, then washed with deionized water, and dried in vacuum to obtain solid silver nanowires.

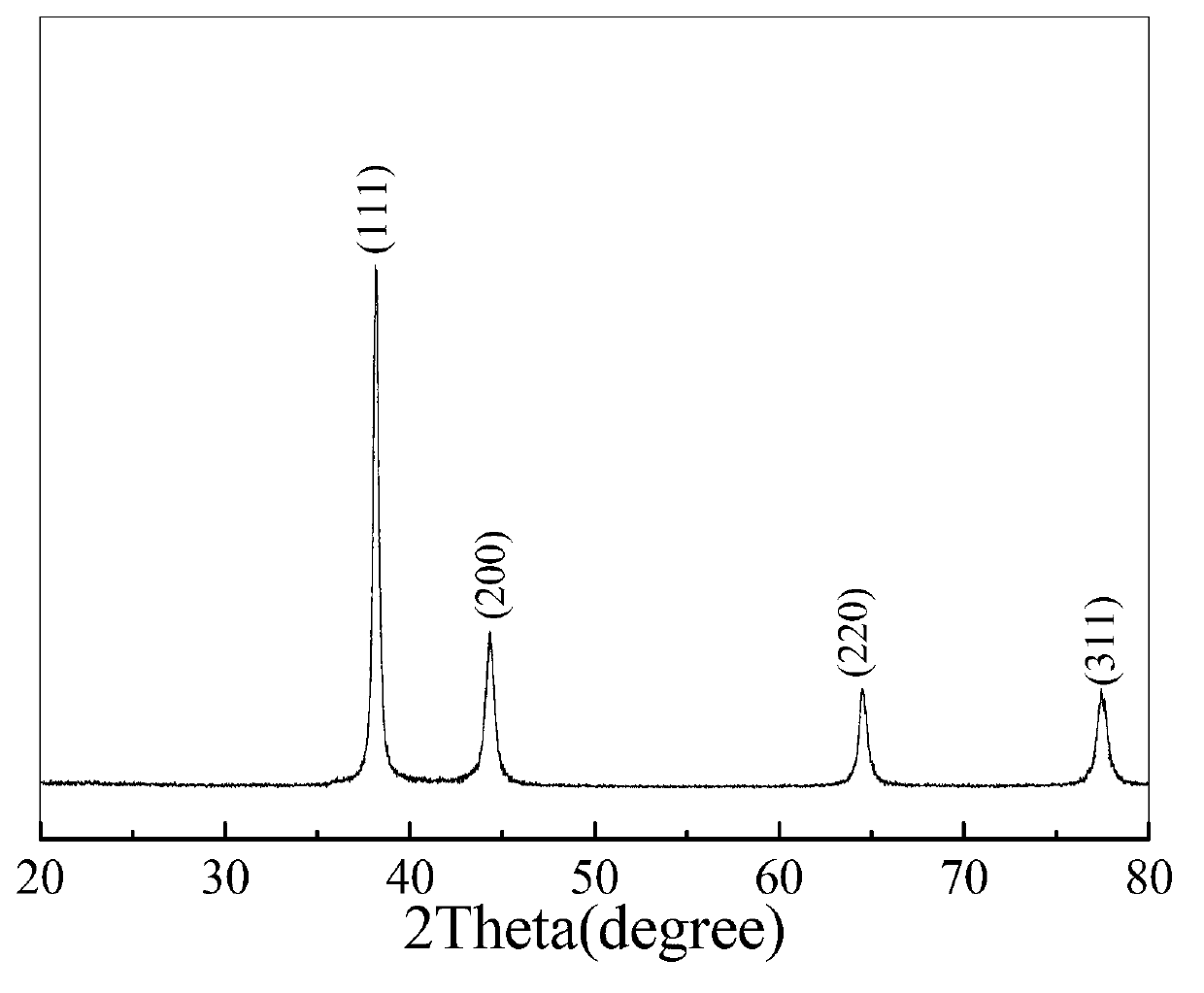

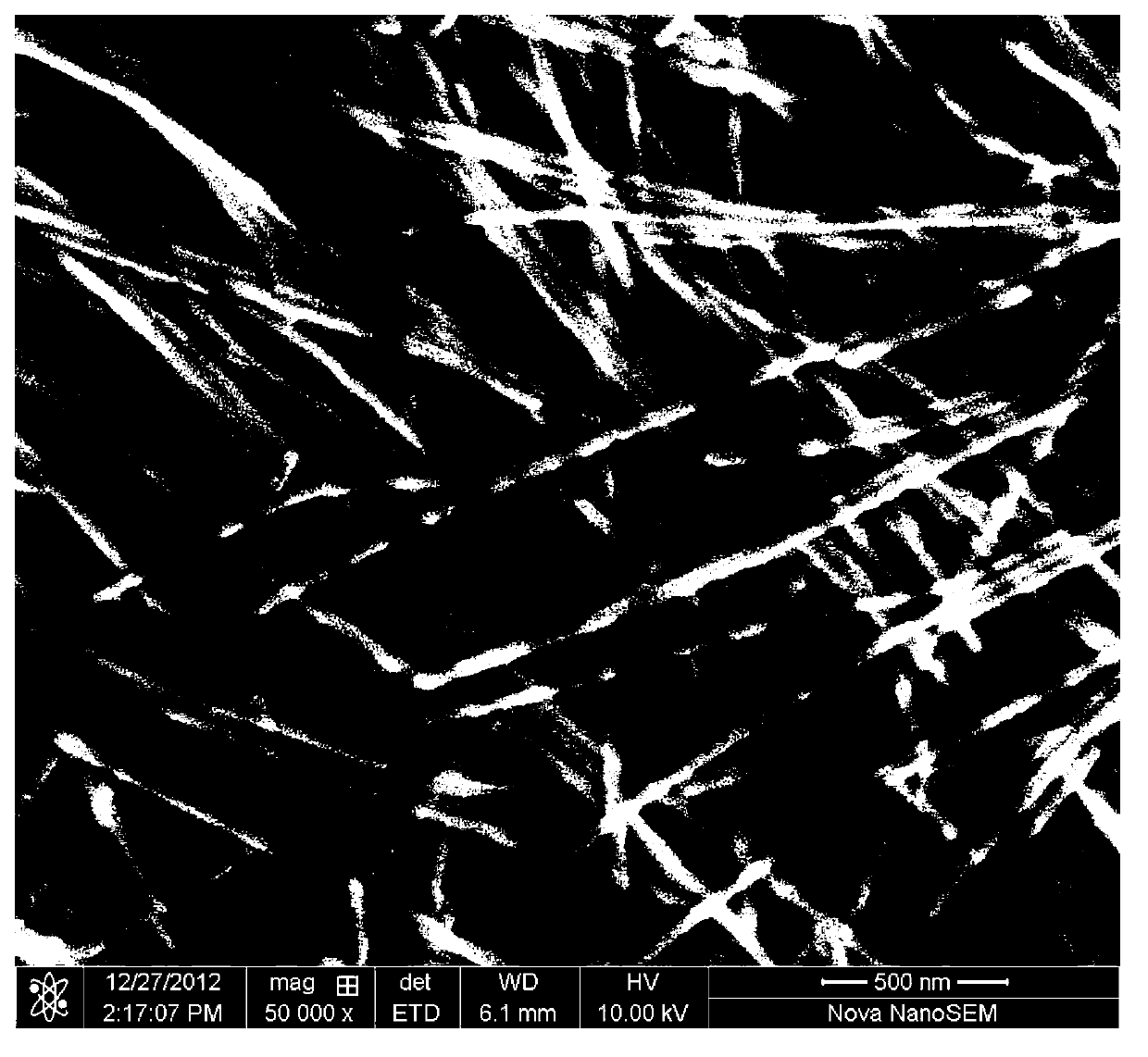

[0062] For field emission scanning electron microscopy (FE-SEM) samples, the powder sample i...

Embodiment 2

[0066] In a 200W ultrasonic water bath, mix 13.6g of silver nitrate and 44.4g of polyvinylpyrrolidone K30 and add it into an aqueous solution containing 100mL of ethylene glycol (the volumes of ethylene glycol and deionized water are 50mL and 50mL respectively), and after uniform dispersion and dissolution A clear solution was obtained.

[0067] 11.7 mg of sodium chloride was added to the above clear solution, and after dissolving, a clear reaction mother liquor was obtained.

[0068] The reaction mother liquor was transferred to a self-pressurized reactor, and the self-pressurized reactor was placed in an oil bath at 120° C., and the mixture was obtained after reacting for 20 minutes.

[0069] The above mixture was cooled to room temperature, and the precipitate was collected after centrifugation, then washed with absolute ethanol, and dried in vacuum to obtain solid silver nanowires.

[0070] For field emission scanning electron microscopy (FE-SEM) samples, the powder sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com