Water-solubility silver nanowire writing ink and preparation method thereof as well as using method thereof

A silver nanowire, water-soluble technology, applied in the preparation of water-soluble silver nanowire ink and its application in the field of transparent conductive film, to achieve the effect of simple process, good conductivity and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The present invention also provides the preparation method of above water-soluble silver nanowire ink, and described preparation method comprises the following steps:

[0057] a) Weigh polyvinyl alcohol and deionized water, under stirring, at 80 o C-100 o C dissolves into a homogeneous transparent solution;

[0058] b), cooling the transparent solution to about 40 o C, add cross-linking agent and catalyst, stir and mix evenly;

[0059] c) adding quantitative silver nanowire aqueous solution and stirring to prepare silver nanowire ink.

[0060] The present invention also provides a method for using the water-soluble silver nanowire ink described above. The ink can be used to prepare a transparent conductive film, which specifically includes the following steps: spraying, rod coating, roller coating, spin coating, and screen printing. The silver nanowire ink forms a uniform film layer on the substrate, and forms a solidly bonded silver nanowire conductive layer on the...

Embodiment 1

[0070] Add 3 g of polyvinyl alcohol (grade 1799) and 300 g of deionized water into a 500 mL three-neck flask equipped with a thermometer, stirrer and reflux condenser, stir and heat to 95 o C, maintain 1h, obtain colorless transparent solution, cool down to about 40 o C, add 0.2g of dimethylolurea and 0.06g of ammonium chloride, stir and dissolve until a colorless transparent solution is obtained, and cool down to about 25 o C. Add 100 g of silver nanowire aqueous solution (10 mg / mL, average diameter 90 nm, average length 30 μm), stir for 30 min, and mix well to prepare water-soluble silver nanowire ink.

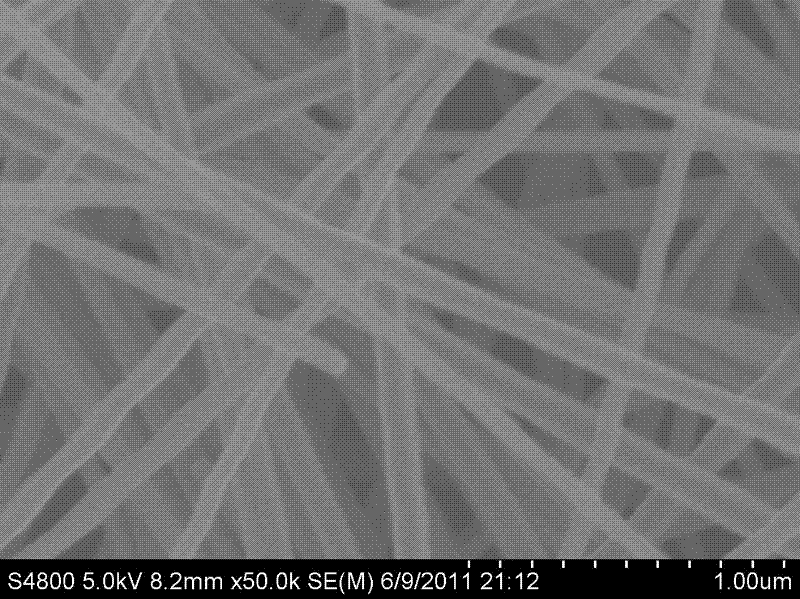

[0071] The corona-treated PET is used as a transparent substrate (visible light transmittance 92.1%), and the silver nanowire ink is used to form a uniform film layer on the substrate by spin coating, 150 o C drying oven for 10min, and then carry out 35atm pressure treatment, namely obtain transparent, conductive, firm transparent conductive film, its scanning electron micr...

Embodiment 2

[0074] Add 5 g of polyvinyl alcohol (grade 2099) and 300 g of deionized water into a 500 mL three-neck flask equipped with a thermometer, stirrer and reflux condenser, stir and heat to 95 o C, maintain 1h, obtain colorless transparent solution, cool down to about 40 o C, add maleic anhydride 1.0g and ammonium sulfate 0.4g, stir and dissolve until a colorless and transparent solution is obtained, cool to about 25 o C. Add 150 g of silver nanowire aqueous solution (15 mg / mL, average diameter 120 nm, average length 70 μm), stir for 30 min, and mix well to prepare water-soluble silver nanowire ink.

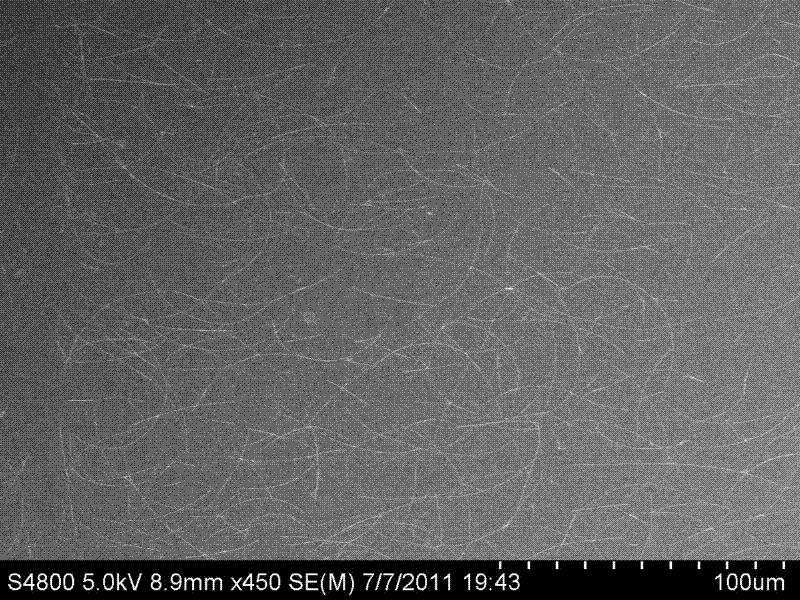

[0075]Using PC treated with UV ozone on the surface as a transparent substrate (visible light transmittance 90.5%), the silver nanowire ink is used to form a uniform film layer on the substrate by spraying, 150 o C oven drying 10min, continue 150 o After heat treatment at C for 30 minutes, a transparent, conductive, and firm transparent conductive film was obtained, with a visible l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com