Composite conductive film, its preparation method and its application

A technology of composite conductive and conductive thin layers, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve problems such as increasing the gap between carbon fiber-rich resin layers, difficulty in resisting lightning strikes, and high resistance of composite materials , to achieve the effect of simple method, high toughness and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The implementation process of the technical solution of the present invention is as follows:

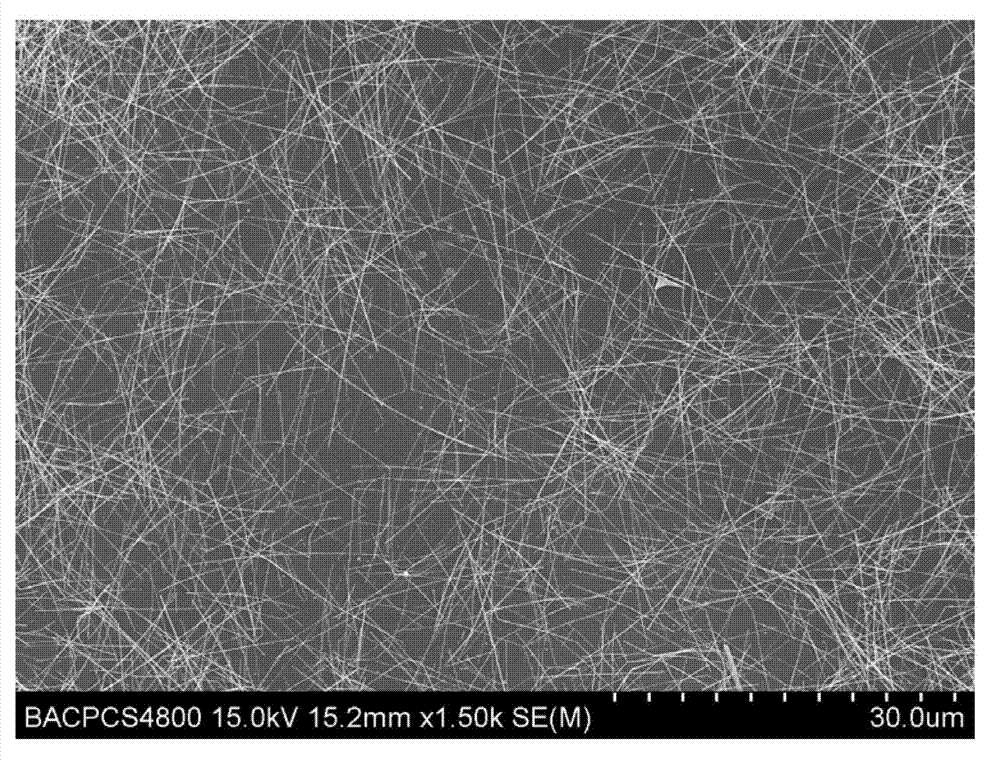

[0030] (1-1) Disperse silver nanowires in ethanol or isopropanol or acetone or ethylene glycol or water to form a dispersion with a concentration of 5 mg / mL or 10 mg / mL;

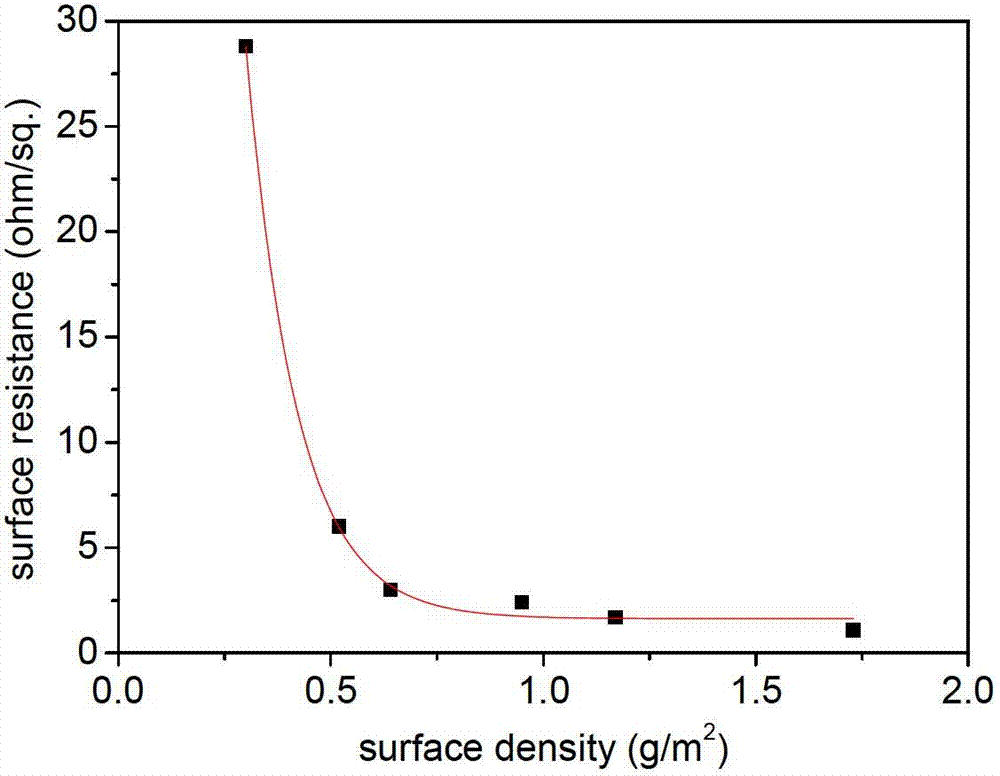

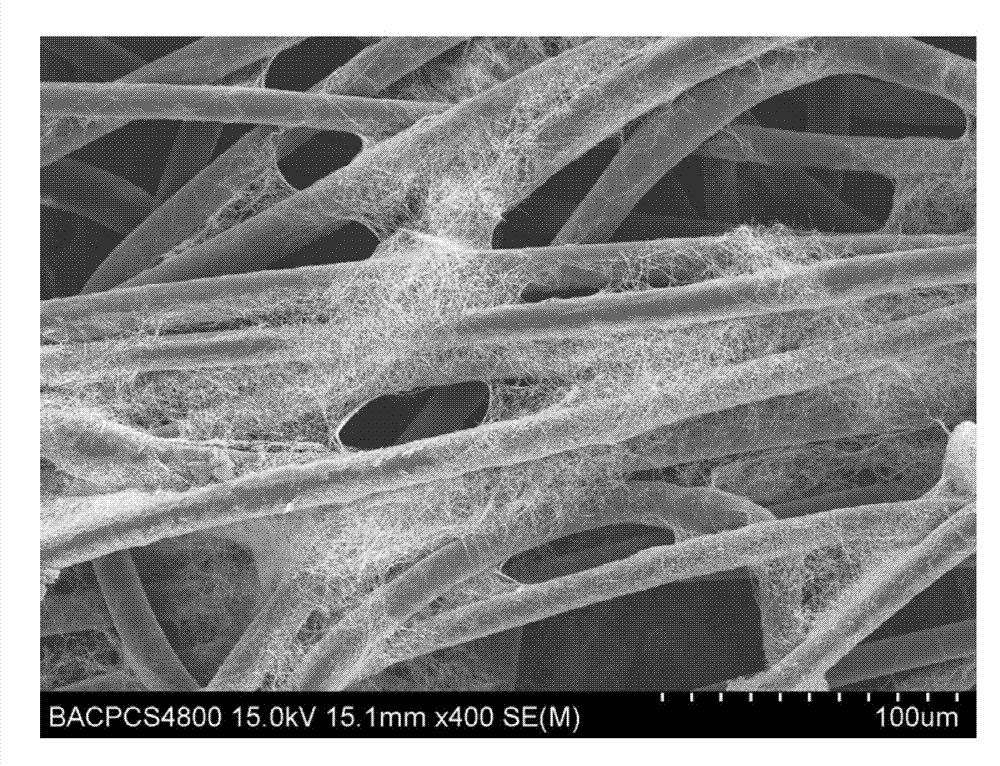

[0031] (1-2) The thickness is 53μm, the surface density is 14g / m 2 Nylon non-woven fabric with a thickness of 25μm and a surface density of 8g / m 2 Polyether ether ketone non-woven fabric or thickness of 75μm, surface density of 26g / m 2 Polyimide non-woven fabric with a thickness of 15μm and a surface density of 7g / m 2 Immerse the polyethersulfone non-woven fabric in the dispersion liquid with a silver nanowire content of 5 mg / mL or 10 mg / mL obtained in the above step (1-1), pull it out of the liquid surface and dry it or dry it, turn it off and then Dipping once to obtain a conductive polymer non-woven fabric uniformly loaded with silver nanowires;

[0032] (1-3) Place the above-mentioned conductive poly...

Embodiment 2

[0039] The implementation process of the technical solution of the present invention is as follows:

[0040] (2-1) Disperse silver nanowires in a 2:1 (V:V) mixture of methanol or isopropanol or acetone or ethanol and water or water to form a dispersion with a concentration of 2 mg / mL or 4 mg / mL;

[0041] (2-2) The thickness is about 20μm, the surface density is 14g / m 2 Polyaryletherketone porous film (porosity about 40%) or thickness about 8μm, area density 6g / m 2 Polyimide porous film or thickness of about 25μm, surface density of 11g / m 2 Polyetherimide porous film or thickness of about 15μm, surface density of 9g / m 2 The polyetheretherketone porous film is dipped into the silver nanowire dispersion described in (2-1), pulled out of the liquid surface and dried, then dipped twice to obtain a conductive film uniformly loaded with silver nanowires. Polymer porous film;

[0042] (2-3) Lay the conductive polymer porous films obtained above on one by one between the layers of ...

Embodiment 3

[0047] The implementation process of the technical solution of the present invention is as follows:

[0048] (3-1) Disperse the silver nanowires in ethanol to form a 5 mg / mL dispersion, and disperse the carboxy-modified carbon nanotubes in water or acetone or DMF to form a 2 mg / mL or 10 mg / mL dispersion.

[0049] (3-2) The above-mentioned dispersion of carboxyl-modified carbon nanotubes (CNTs) with a solid concentration of about 2 mg / mL or 10 mg / mL is loaded on a surface with a thickness of 35 μm and an area density of 14 g / mL by filtering under negative pressure. m 2 Nylon fabric with a thickness of 25μm and a surface density of 11g / m 2 Polyether ether ketone fabric or thickness of 45μm, area density of 18g / m 2 After drying, the CNT-loaded thin layer fabric is immersed in the ethanol dispersion with a silver nanowire content of 5mg / mL, pulled out of the liquid surface and dried to obtain silver nanowires and carbon nanowires. Conductive thin layer fabric attached to the tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com