Quick and efficient synthesis method for silver nanowires

A technology of silver nanowires and synthesis methods, which is applied in the field of rapid and efficient synthesis of silver nanowires, can solve the problems of long reaction time, low reaction concentration, and low selectivity of nanowires, and achieve short reaction time, high reaction efficiency, and improved The effect of preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

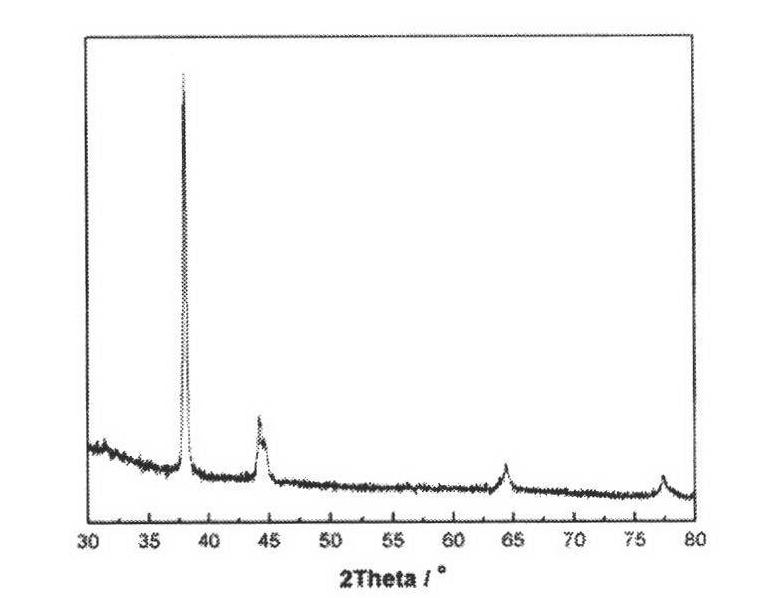

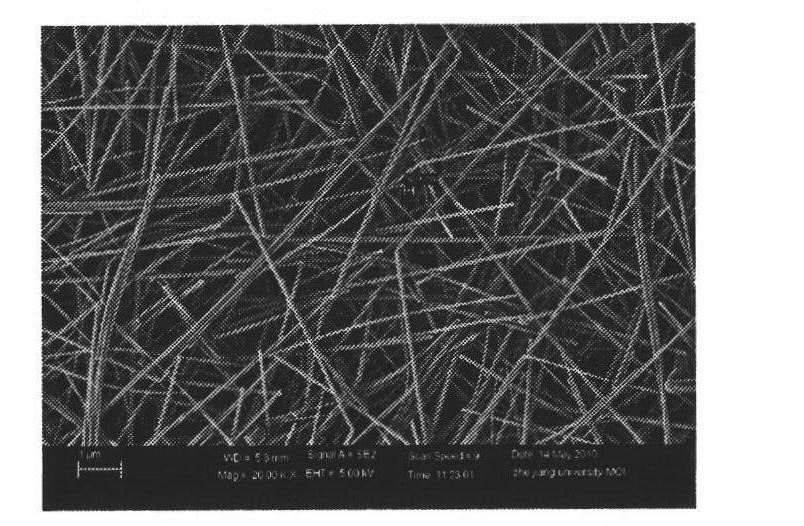

[0024] 1) Pass inert gas into the reactor, add 10ml of ethylene glycol, stir, heat to about 180°C, condense and reflux, and preheat for 25min; quickly add 5ml of silver nitrate ethylene glycol solution with a molar concentration of 0.1M, At the same time, slowly drop 10ml of PVP with a molar concentration of 0.15M and MnCl of 16μM 2 The mixed ethylene glycol solution was added dropwise for 10 minutes, reacted for 90 minutes, and cooled to room temperature to obtain the reaction mother liquor of silver nanowires.

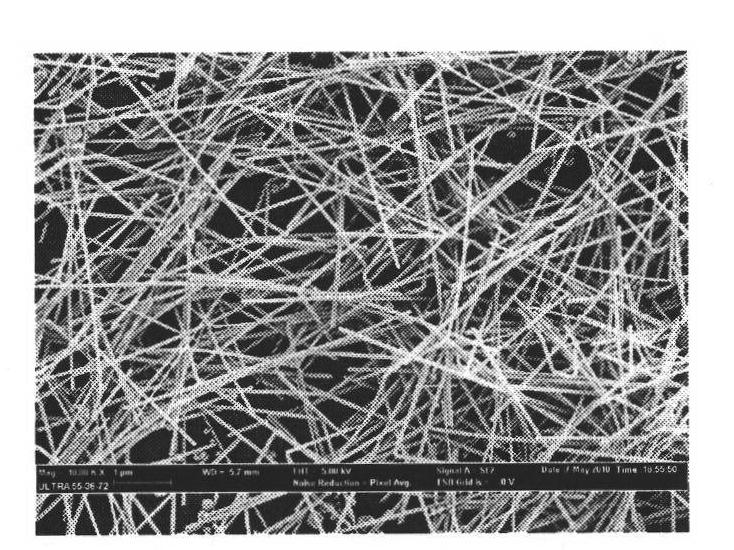

[0025] 2) Transfer the silver nanowire reaction mother liquid into a centrifuge tube, add acetone with 2 times the volume of the reaction mother liquid, centrifuge at a speed of 2700rpm, remove the supernatant, leave the precipitate, add 2 times the volume of the reaction mother liquid Deionized water or ethanol is centrifuged at 2700 rpm, the supernatant is removed, and the precipitate is left. Repeat this operation twice, and the precipitate is extracted and disper...

Embodiment 2

[0028] 1) Pass inert gas into the reactor, add 10ml of ethylene glycol, stir, heat to about 180°C, condense and reflux, and preheat for 10 minutes; quickly add 5ml of silver nitrate ethylene glycol solution with a molar concentration of 0.1M, At the same time, slowly drop 10ml of PVP with a molar concentration of 0.15M and MnCl of 16μM 2 The mixed ethylene glycol solution was added dropwise for 10 minutes, reacted for 25 minutes, and cooled to room temperature to obtain the reaction mother liquor of silver nanowires.

[0029] 2) Transfer the silver nanowire reaction mother liquid into a centrifuge tube, add acetone with 1 times the volume of the reaction mother liquid, centrifuge at a speed of 2500rpm, remove the supernatant, leave the precipitate, add 1 times the volume of the reaction mother liquid Deionized water or ethanol is centrifuged at 2500 rpm, the supernatant is removed, and the precipitate is left. This operation is repeated twice, and the precipitate is extracted ...

Embodiment 3

[0032] 1) Pass inert gas into the reactor, add 10ml of ethylene glycol, stir, heat to about 180°C, condense and reflux, and preheat for 25min; quickly add 5ml of silver nitrate ethylene glycol solution with a molar concentration of 0.1M, At the same time, slowly drop 10ml of PVP with a molar concentration of 0.15M and MnCl of 16μM 2 The mixed ethylene glycol solution was added dropwise for 10 minutes, reacted for 8 minutes, and cooled to room temperature to obtain the reaction mother liquor of silver nanowires.

[0033] 2) Move the silver nanowire reaction mother liquid into a centrifuge tube, add acetone with 2 times the volume of the reaction mother liquid, centrifuge at a speed of 2500rpm, remove the supernatant, leave the precipitate, add 2 times the volume of the reaction mother liquid Deionized water or ethanol is centrifuged at 2500 rpm, the supernatant is removed, and the precipitate is left. This operation is repeated three times, and the precipitate is extracted and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com