Flexible and transparent electrode film based on silk fibroin and manufacturing method and application thereof

A silk fibroin, transparent electrode technology, applied in cable/conductor manufacturing, conductive layers on insulating carriers, circuits, etc., can solve the problem of not having good biocompatibility and light transmittance, reducing device conversion efficiency, and improving substrates Production cost and other issues, to achieve the effects of non-toxic and non-irritating excellent, overcoming poor binding performance and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

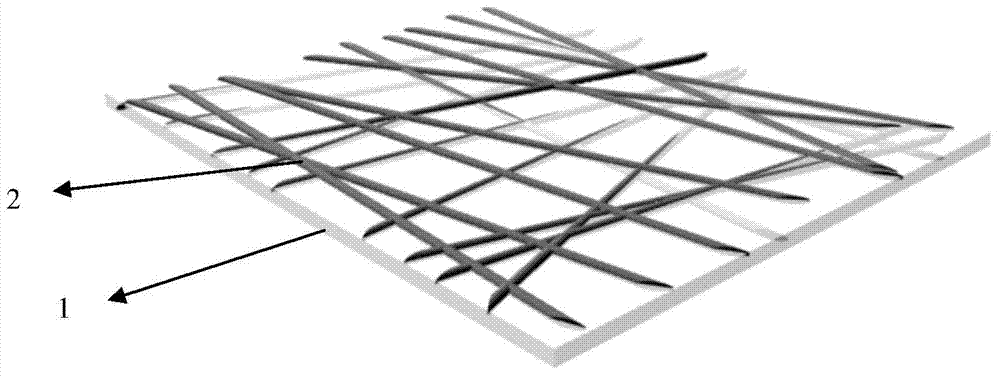

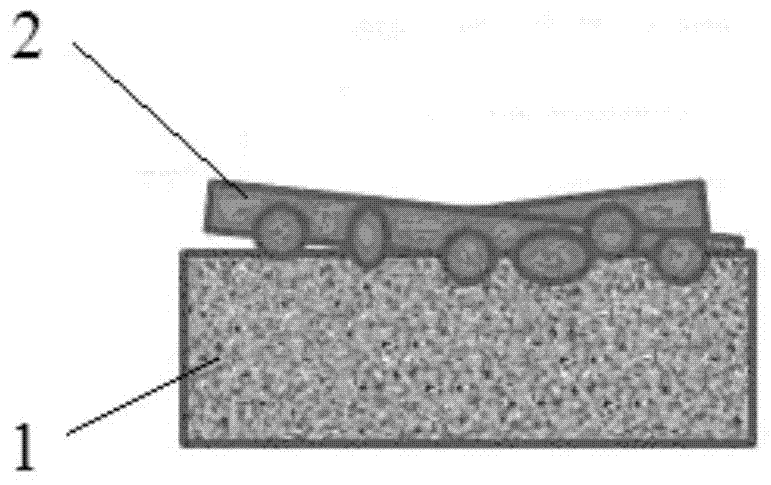

[0046] Example 1: Combining figure 1 , figure 2 As shown, the technical solution of the present invention provides a flexible transparent electrode film based on silk fibroin, which is composed of a flexible support layer and a conductive layer, wherein the conductive layer is a silver nanowire film composed of a silver nanowire interweaving network 2 , and the flexible supporting layer is a silk fibroin film 1 formed by bonding the silk fibroin solution to the silver nanowire film through van der Waals force after drying and curing.

[0047] The film uses silk fibroin film 1 as a flexible support layer, which has good biocompatibility, biodegradability, non-toxic and non-irritating and excellent optical properties, has a good affinity with the human body, and its degradation process is also controllable of. Moreover, the silk fibroin film 1 has good light transmission performance in the range of visible light, and it can be used as a supporting layer of electrode materials...

Embodiment 2

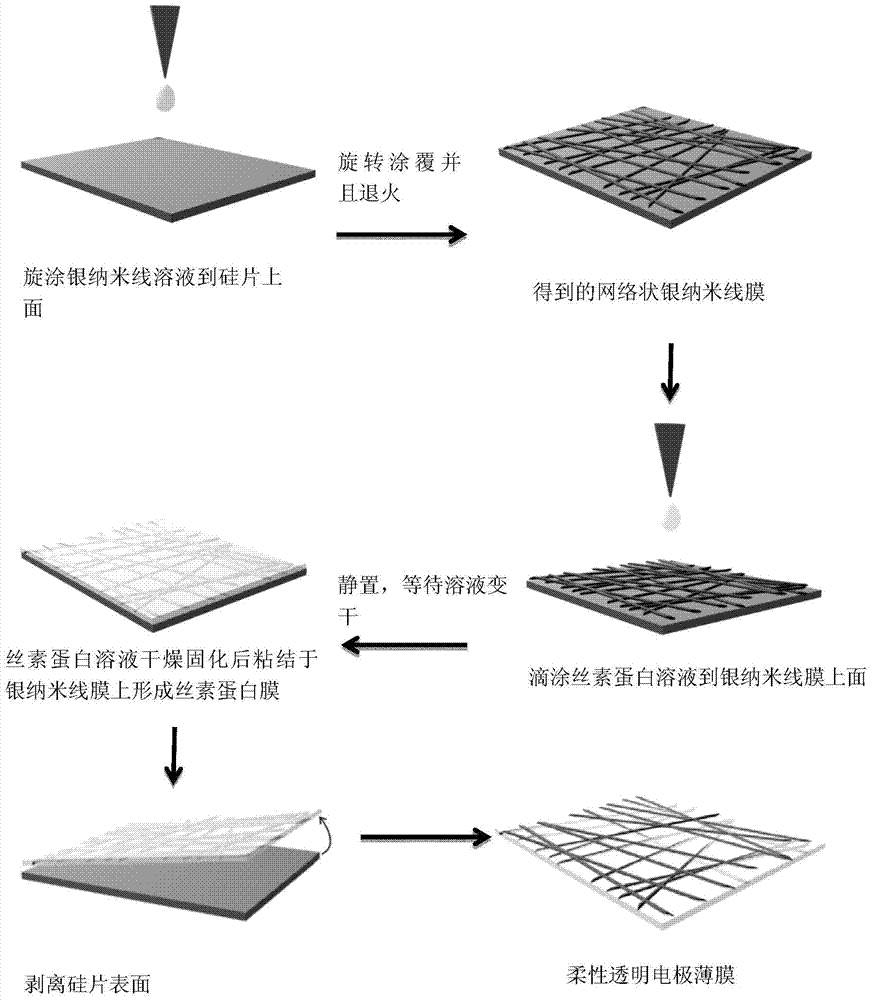

[0048] Embodiment 2: The preparation method of the silk fibroin-based flexible transparent electrode film provided in embodiment 1, the preparation process can be found in image 3 Shown:

[0049] (1) Ultrasonic wash the cut silicon wafers with ethanol, acetone, and water in sequence, and then dry the surface with dry nitrogen;

[0050] (2) Spin-coat the silver nanowire solution (purchased from Blue nano company, the diameter of the silver nanowire is between 30-40 nanometers, and the solvent is ethanol or isopropanol) (shaking for 5-10 minutes before use) in step (1) ) the surface of the finally obtained silicon wafer (spin-coating speed 3000 rpm, time 1 minute), and then annealed to form a layer of network-like silver nanowire film (AgNWs). The thickness of the silver nanowire film is about 120 microns.

[0051] (3) Prepare pure silk fibroin solution by conventional means first, the steps are as follows:

[0052] A. Use boiling 0.5% NaCO to silk 3 The solution is degumme...

Embodiment 3

[0071] Example 3: Using the AgNWs-SF thin film of the present invention as a substrate, an example of its application in the preparation of organic photovoltaic cells is illustrated.

[0072] Preparation of battery:

[0073] (1) Dissolve 2mg of PFN in 1mL of anhydrous methanol, stir and dissolve for 30 minutes, add 20uL of acetic acid, and rotate to dissolve for more than 12 hours;

[0074] (2) Connect PTB7 and PC 71 Dissolve BM in chlorobenzene at a ratio of 1:1.5, add 3% DIO solution, stir and dissolve for more than 12 hours;

[0075] (3) Spin-coat the PFN solution prepared at the end of step (1) on the AgNWs surface of the AgNWs-SF film of the present invention (the spin-coating speed is 4000 rpm, and the time is 1 minute), and then spin-coat PTB7:PC 71 BM mixed solution (spin coating speed 1000 rpm, time 1 min) to form PTB7:PC 71 BM layer;

[0076] (4) In a vacuum evaporator (the degree of vacuum is less than 10×10 -7 mbr) PTB7:PC formed at the end of step (3) 71 Eva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com