Metal oxide microparticles, transparent conductive film, and dispersion

a technology of metal oxide microparticles and transparent conductive films, applied in the field of new materials, can solve the problems of limited application and inferior storage stability of transparent conductive films disclosed in these proposals, and achieve the effect of high transparency and conductivity, excelling in flexibility and storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

production example 1

—Preparation of Silver Nanowires 1—

[0099]170 ml of ethylene glycol was heated at 160° C. for one hour. 50 ml of ethylene glycol solution of 0.1 mM chloroplatinic acid (IV) hexahydrate was added thereto. Seperately, 1.70 g of silver nitrate and 2.25 g of polyvinyl pyrrolidone (weight-average molecular weight 40,000) were dissolved in 200 ml of ethylene glycol. The resulting solution was added at a rate of 6 ml per minute. After the addition, the mixture was further heated at 160° C. for 30 minutes and then cooled to room temperature. Ethanol was added to the mixture, followed by centrifugation to purify the product. The product was dispersed by the addition of N,N-dimethylformamide to thereby prepare a dispersion containing 2% Ag by mass.

[0100]For the prepared dispersion, the length and width of the silver nanowires were measured and an aspect ratio was determined. It was found that silver nanowires 1 were formed that have a length (major axis length) of several μm, a width (minor ax...

production example 2

—Preparation of Ag Nanoparticles 1—

[0101]3.4 g of silver nitrate and 4.2 g of polyvinylpyrrolidone (weight-average molecular weight 40,000) were dissolved in 200 ml of water. To this solution, was added 20 ml of 2-diethylaminoethanol and stirred for 20 minutes to obtain a yellowish brown reaction product. Ethanol was added to the mixture, followed by centrifugation to purify the product. The product was dispersed by the addition of N,N-dimethylformamide to thereby prepare a dispersion containing 2% Ag by mass.

[0102]Ag nanoparticles 1 with a mean particle diameter of 8 nm were formed in the prepared dispersion.

production example 3

—Preparation of Metal Oxide Microparticles 1—

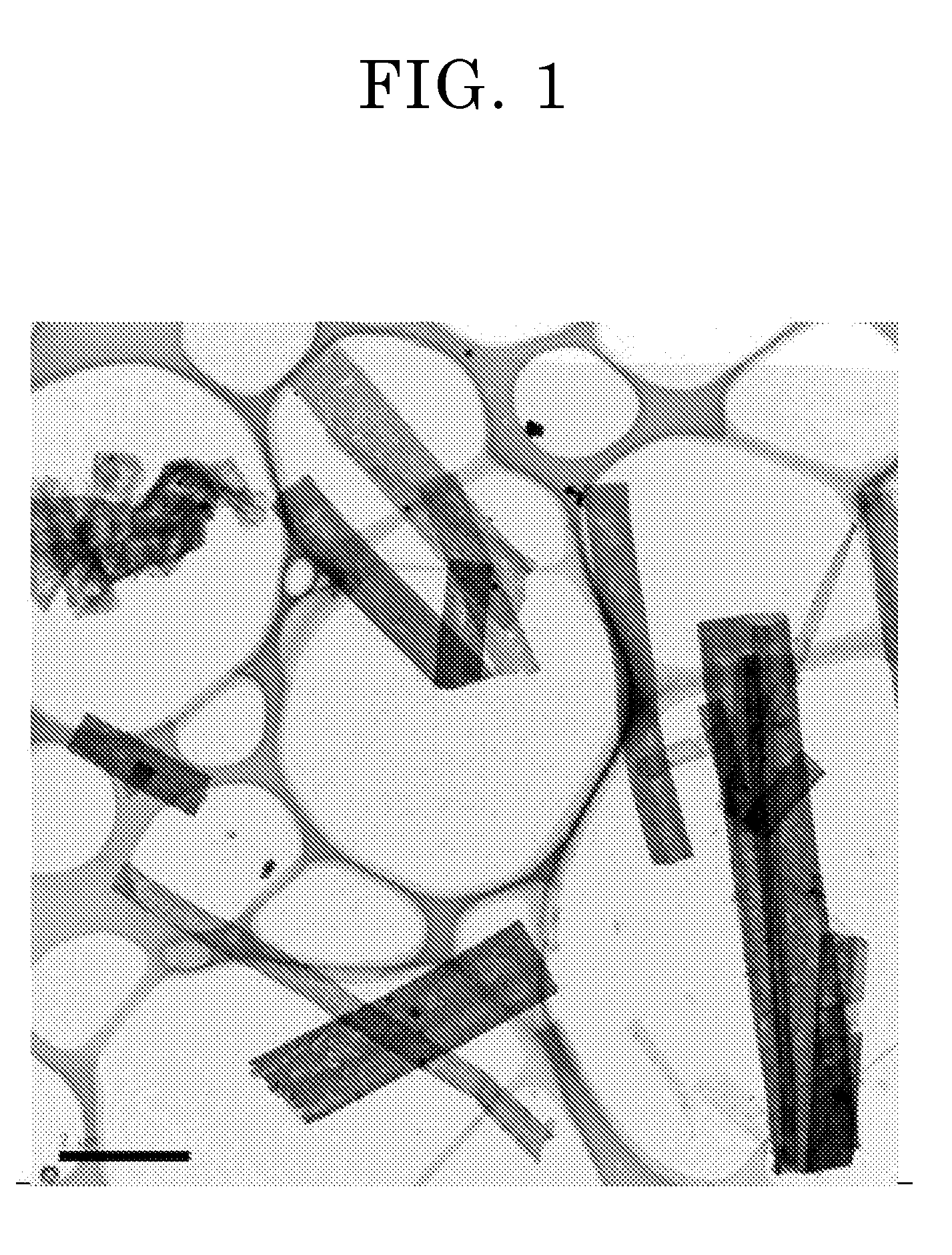

[0103]0.66 g of zinc acetate dihydrate and 30 mg of aluminum (III) isopropoxide were dissolved in 30 ml of ethylene glycol. To this solution, was added 1.20 g of sodium hydroxide dissolved in 60 ml of ethylene glycol. The mixture was stirred for 8 hours while heating at 170° C. After cooling to room temperature, ethanol was added to the mixture, followed by centrifugation to thereby purify the product. Then, the product was dispersed in a mixture of 60 vol. % isopropanol, 20 vol. % N-methylpyrrolidone, and 20 vol. % ethylene glycol using a nanomizer (product of Tokai Corporation) to prepare a dispersion containing 10% AZO by mass.

[0104]For the prepared dispersion, it was found that AZO (Al-doped ZnO) nanosheets were formed that had a width (minor axis length) and a length (major axis length) of 50 nm to several μm, respectively, and had an average thickness of 200 nm (FIG. 1). X-ray diffraction (XRD; product of Rigaku Denki Co., RINT2500)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| mean particle diameter | aaaaa | aaaaa |

| mass ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com