High optical transparent two-dimensional electronic conducting system and process for generating same

a two-dimensional electronic conducting system and high optical transparency technology, applied in the field of transparent conducting materials, can solve the problems of increasing brittleness, increasing brittleness, and relatively high cost of ito, and achieve good percolation transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

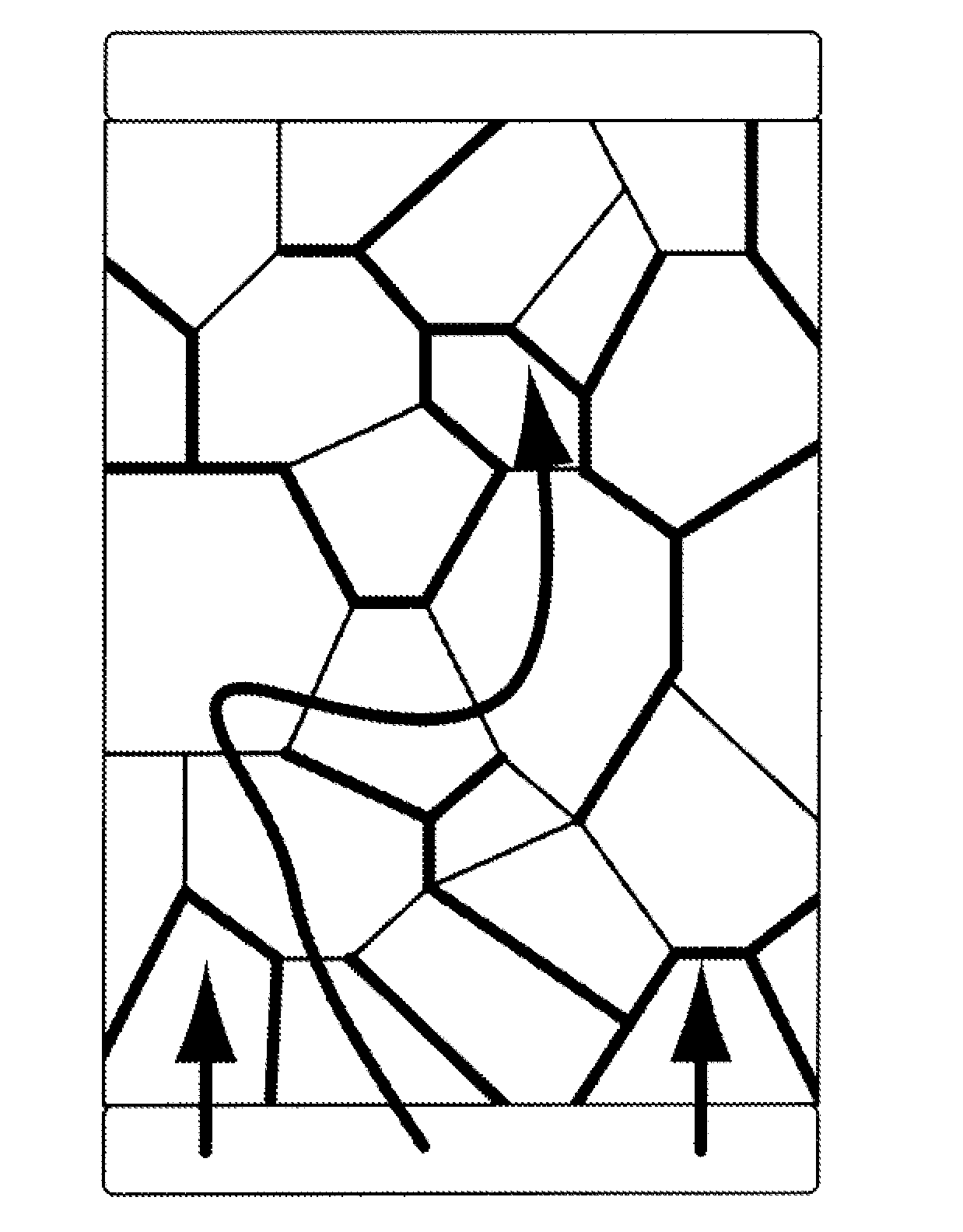

[0075]Commercial CVD SLG on copper foil (ACS Materials Co., MA) was employed. Standard procedures were followed for plasma etching of SLG from back side of Cu and layer transfer onto a 1 cm×1 cm quartz substrate (SPI Supplies, PA), including copper etching using iron nitrate solution (X. Li, et al., Science (2009), 324,1312). Commercial AgNWs (Blue Nano Inc., NC), with diameters of 70-110 nm and lengths of 20-60 μm, are dispersed in isopropyl alcohol at a concentration of 0.1 mg mL−1. AgNW networks were drop cast either after (Hybrid 1) or before (Hybrid 2) SLG transfer, with density controlled by number of drops. Finally, the hybrid films were annealed for 1 hour in forming gas at 300° C. with a 40 sccm flow rate. The schematic process flow of SLG transfer and fabrication of hybrid films is shown in FIGS. 10, 11a and 11b. SLG and Hybrid 2 films were also fabricated on transparent, flexible PET substrates (from Dupont) for mechanical bending tests.

[0076]Raman spectra and Raman spati...

example 2

[0077]CTLM electrode with channel lengths of ≈7, 22, 49 and 100 μm were fabricated by evaporation of Ti / Pd / Au (thickness 1 nm / 30 nm / 20 nm) in a Kurt J. Lesker electronbeam evaporator with base pressure of ≈9×10−7 Torr, followed by lift-off. Two-terminal current vs. voltage measurements were performed using a probe station (Cascade Microtech.), Keithley 7174A switch matrix system, and a Keithley 4200 SCS semiconductor parameter analyzer. Sheet resistances were measured using CTLM, with geometry correction before sheet resistance calculation. Results can be found in Supporting Information, Figure S3 of Chen et al.

Testing and Results

[0078]Specular and Diffusive Transmittance:

[0079]Since the surfaces of the hybrid films are textured, it is important to characterize their diffusive and specular transmittances. The diffusive spectra for the (i) quartz substrate, (ii) quartz with SLG, and (iii) the quartz with hybrid films were all measured at normal incidence using a Perkin Elmer (lambda ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| sheet resistance | aaaaa | aaaaa |

| sheet resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com