Preparation method of semi-interpenetrating network polymer gel electrolyte membrane

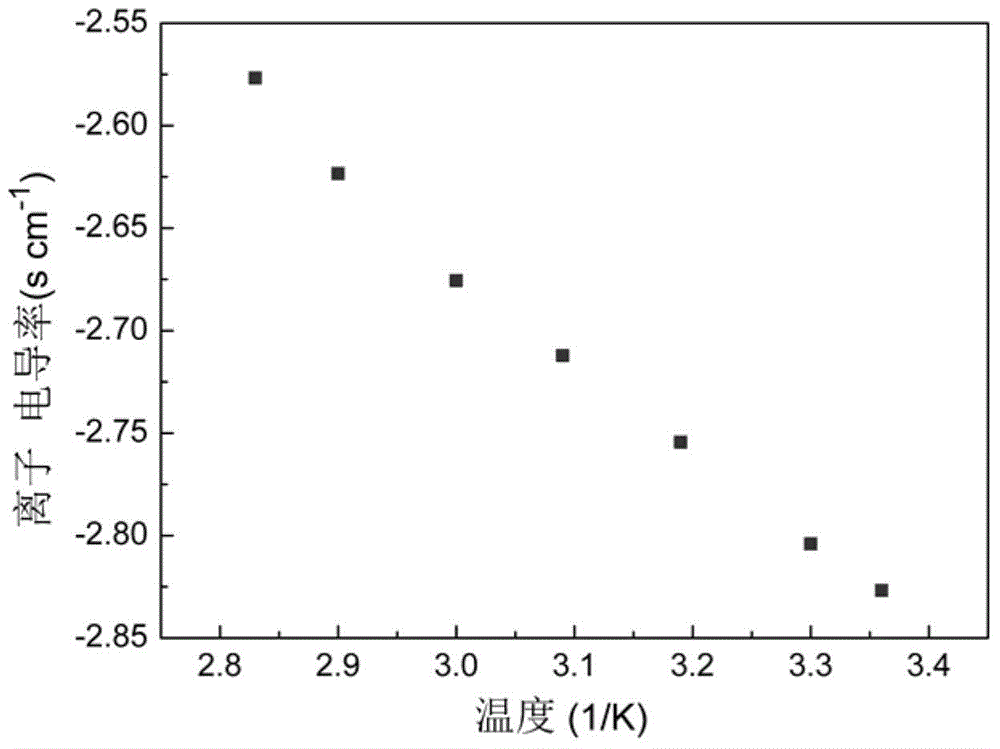

A technology of semi-interpenetrating network and gel electrolyte, which is applied in the field of preparation of semi-interpenetrating network polymer gel electrolyte membrane, which can solve the problems of difficult to meet the actual use requirements, low porosity of polyolefin separator, poor dimensional stability at high temperature, etc. , to achieve excellent mechanical properties, reduce activation energy, and good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

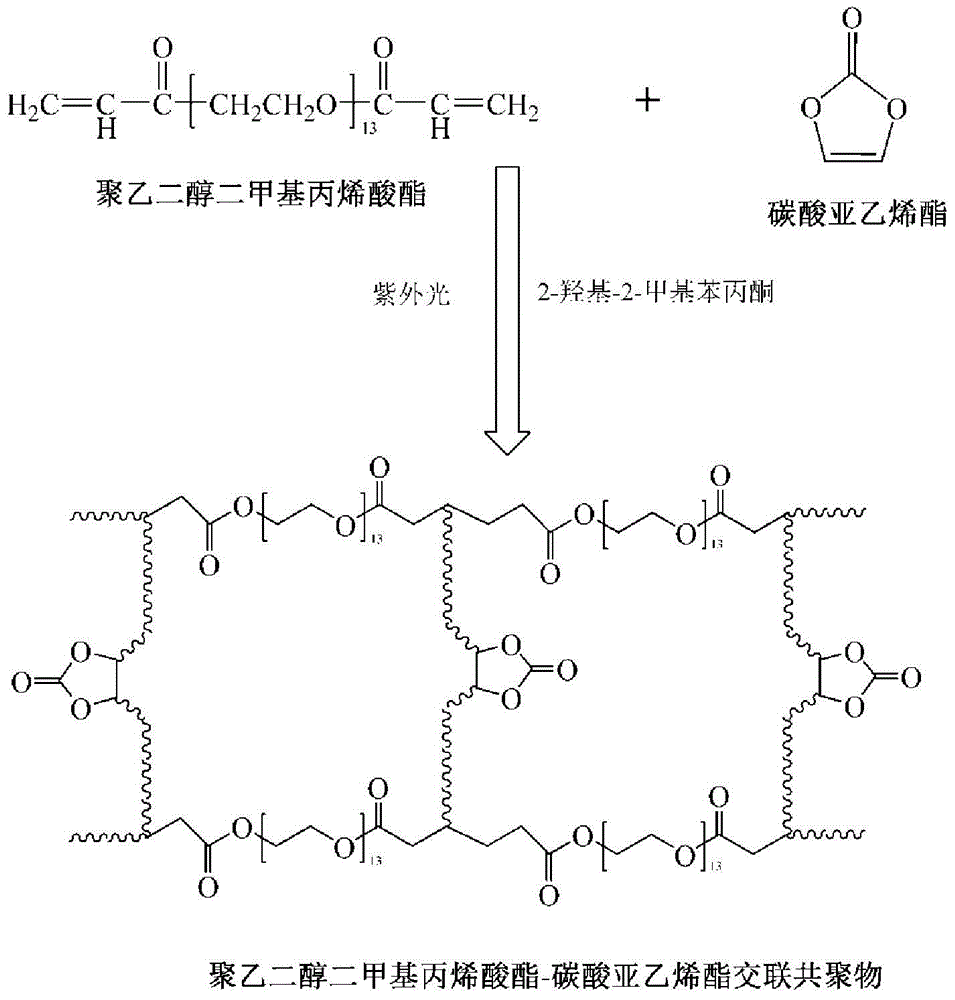

[0039] This embodiment relates to a method for preparing a semi-interpenetrating network polymer gel electrolyte membrane, the method comprising the following steps:

[0040] (1) Add 0.5g of polyvinylidene fluoride-hexafluoropropylene in a 25ml sample bottle, then dropwise add 5g of acetone, stir to make it dissolve completely, then weigh 0.5g of polyethylene glycol dimethacrylate ( Mn=575), 2.0g of vinylene carbonate and 0.015g of photoinitiator 2-hydroxyl-2-methylpropiophenone were added into the sample bottle, stirred and mixed evenly. Apply the above solution on a clean glass plate, cover it with a layer of glass plate to form a sandwich structure, and then place it at a distance of 15 cm below the UV lamp. After 90 seconds of radiation curing (the temperature of radiation curing is 35 ° C), that is Prepare UV-cured semi-IPN polymer film;

[0041] (2) The prepared semi-interpenetrating network polymer membrane was washed three times with absolute ethanol to remove residua...

Embodiment 2

[0054] This embodiment relates to a method for preparing a semi-interpenetrating network polymer gel electrolyte membrane, the method comprising the following steps:

[0055] (1) Add 0.2g of polyacrylonitrile into a 25ml sample bottle, then dropwise add 5g of N,N-dimethylformamide, stir to dissolve it completely, and then weigh 0.5g of polyethylene glycol dimethyl Add acrylate (Mn=350), 2.0 g of vinylene carbonate and 0.006 g of photoinitiator benzoin into the sample bottle, stir and mix evenly. Apply the above solution on a clean glass plate, cover it with a layer of glass plate to form a sandwich structure, and then place it at a distance of 10 cm below the UV lamp. After 60 seconds of radiation curing (the temperature of radiation curing is 25 ° C), that is A UV-cured semi-IPN polymer film was prepared.

[0056] (2) The prepared semi-interpenetrating network polymer membrane was washed three times with absolute ethanol to remove residual monomers and solvents on the surfac...

Embodiment 3

[0059] This embodiment relates to a method for preparing a semi-interpenetrating network polymer gel electrolyte membrane, the method comprising the following steps:

[0060] (1) Add 0.5g of polysulfone to a 25ml sample bottle, then dropwise add 5g of N,N-dimethylformamide, stir to dissolve it completely, and then weigh 0.5g of polyethylene glycol dimethacrylic acid Esters (Mn=1000), 2.0 g of vinylene carbonate and 0.0125 g of photoinitiator azobisisobutyronitrile were added into the sample bottle, stirred and mixed evenly. Apply the above solution on a clean glass plate, cover it with a layer of glass plate to form a sandwich structure, and then place it at a distance of 20cm below the UV lamp. After 150S of radiation curing (the temperature of radiation curing is 0°C), that is A UV-cured semi-IPN polymer film was prepared.

[0061] (2) The prepared semi-interpenetrating network polymer membrane was washed three times with absolute ethanol to remove residual monomers and sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com