Composite proton exchange membrane and preparation method thereof

A proton exchange membrane and proton exchange technology, applied in solid electrolyte fuel cells, fuel cells, electrochemical generators, etc., can solve the problems of proton exchange membrane fuel cell characterization and achieve low fuel permeability, high proton conductivity, The effect of low activation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

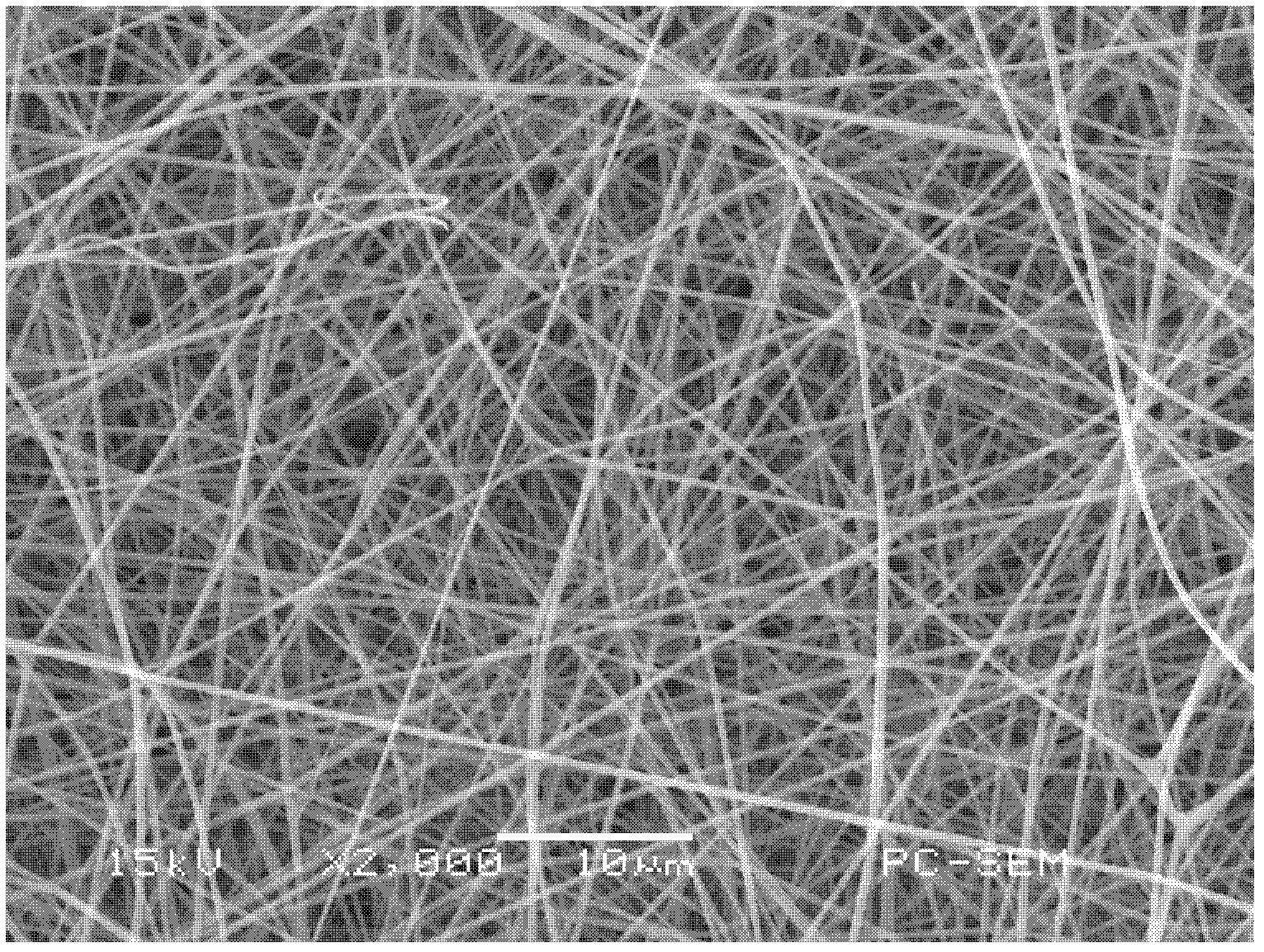

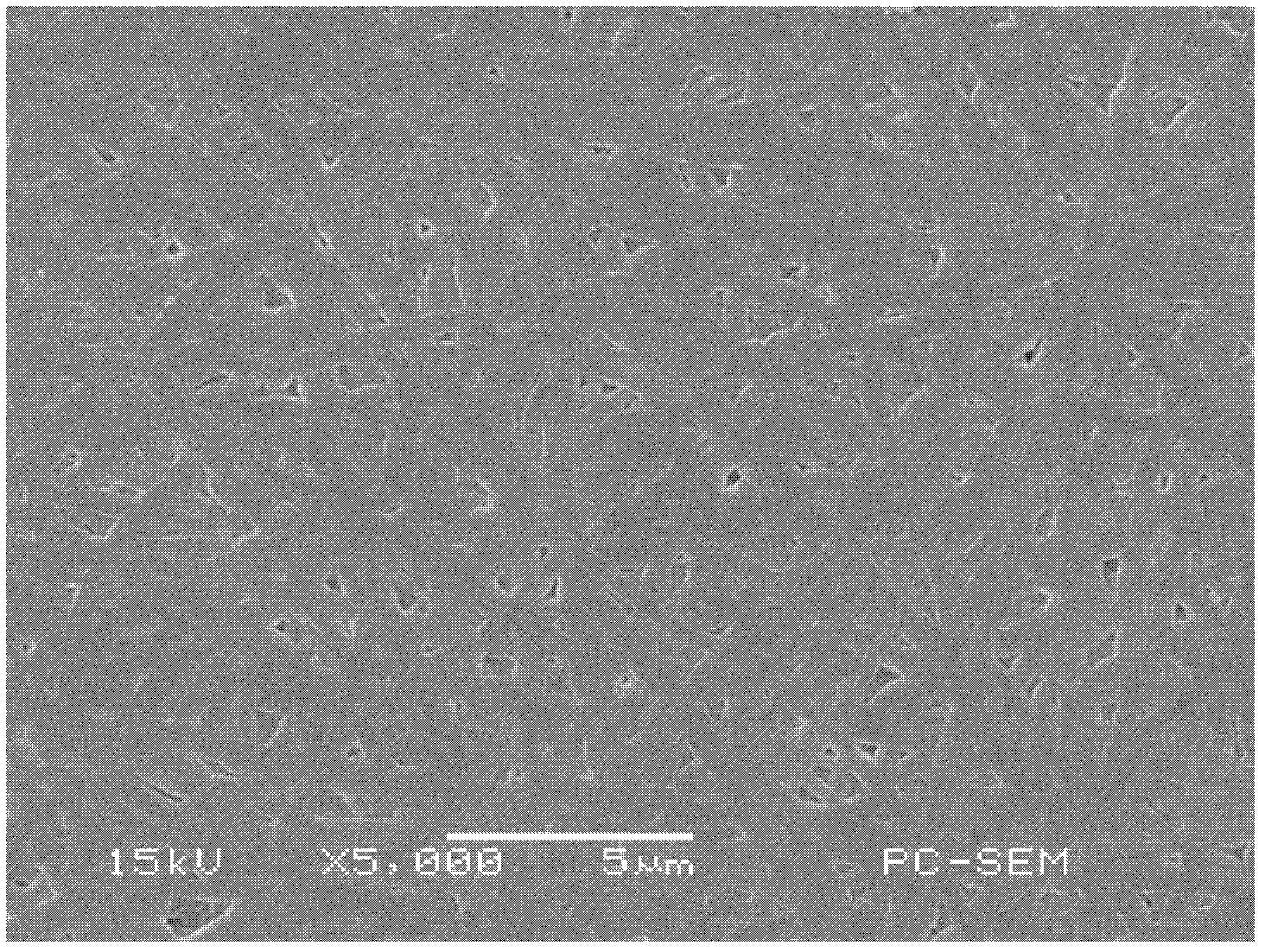

[0041] A sulfonated polyaryletherketone proton exchange membrane material is dissolved in dimethylacetamide to prepare a solution for electrospinning with a mass fraction of 30%; polyethersulfone is dissolved in dimethylacetamide to prepare a mass fraction of 20% % solution for electrospinning; add the two prepared electrospinning solutions to the two spinnerets of the electrospinning device respectively, the spinneret moves back and forth at a speed of 1mm / s, a moving distance of 80mm, and a voltage of 30KV. The spinning temperature was 40°C, resulting in a chemically heterogeneous electrospun fiber membrane based on two fibers.

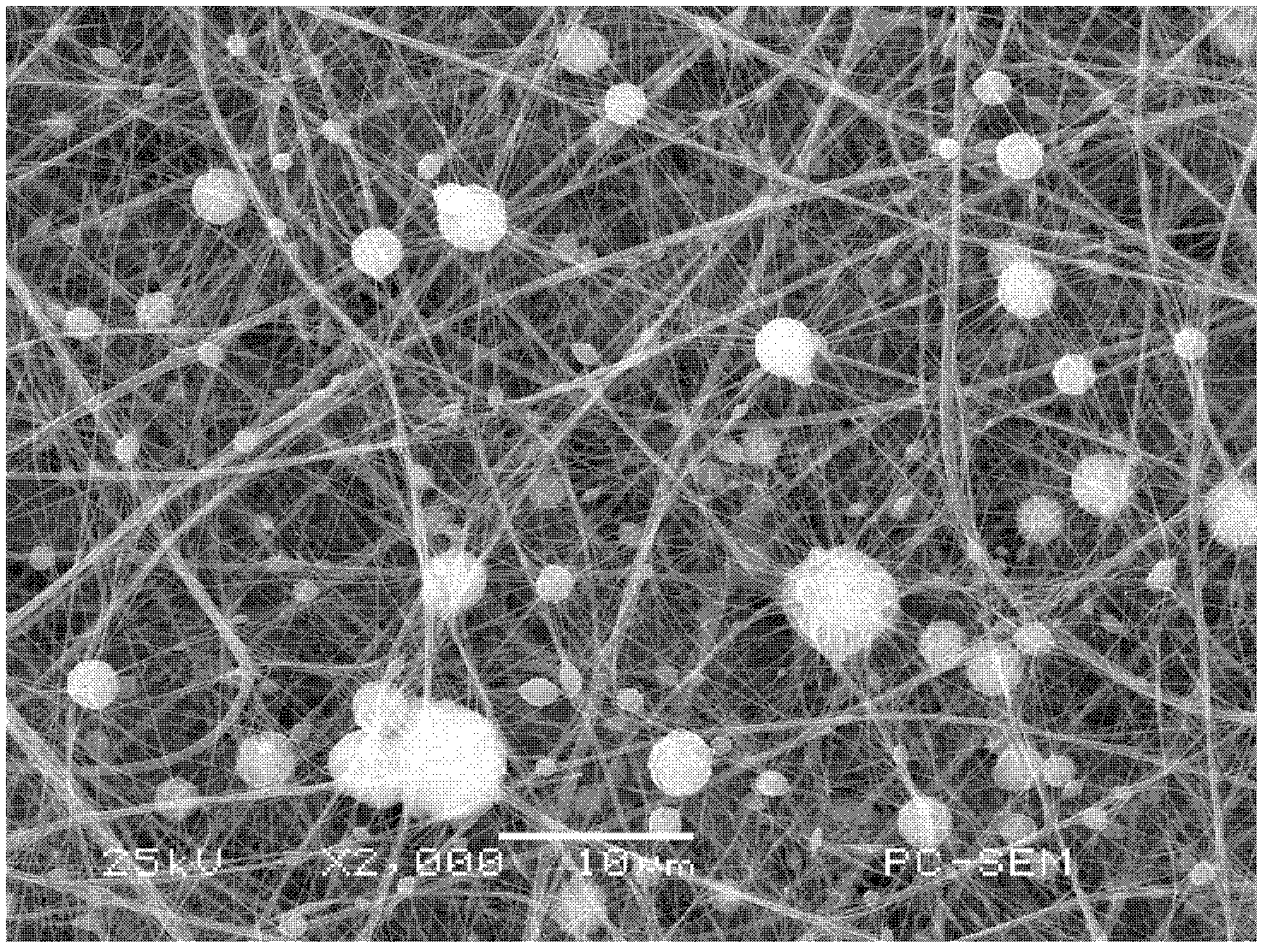

[0042] Immerse the obtained chemically heterogeneous electrospinning fiber membrane in a 1.5 mg / ml polydimethyldiallyl ammonium chloride aqueous solution, absorb and equilibrate for 10 minutes, wash with deionized water for 10 minutes, and blow dry in the air; The dried chemically heterogeneous electrospinning fiber membrane was immersed in a 1.5 mg...

Embodiment 2

[0045] The mixture of perfluorosulfonic acid resin Nafion and polyethylene oxide is prepared into methanol solution, the total mass fraction of perfluorosulfonic acid resin Nafion and polyethylene oxide in the solution is 40%, and the mass of polyethylene oxide is perfluorosulfonic acid resin Nafion 0.01% of the mass, polyethersulfone was dissolved in dimethylacetamide to prepare a solution with a mass fraction of 20%. The two solutions were respectively added to the two spinnerets of the electrospinning device, the spinneret moved back and forth at a speed of 1mm / s, a moving distance of 80mm, a voltage of 18KV, and spun under ambient temperature conditions to obtain a two-fiber-based spinneret. Chemically heterogeneous electrospun fiber membranes.

[0046] The obtained chemically heterogeneous electrospinning fiber membrane was immersed in a 1.5 mg / ml polydimethyldiallyl ammonium chloride aqueous solution, adsorbed and equilibrated for 10 minutes, washed with deionized water ...

Embodiment 3

[0049] The sulfonated polystyrene was dissolved in water to prepare an electrospinning solution with a mass fraction of 30%; polyethersulfone was dissolved in dimethylacetamide to prepare an electrospinning solution with a mass fraction of 20%; the prepared two The electrospinning solution was added to the two spinnerets of the electrospinning device respectively, the spinneret moved back and forth at a speed of 1mm / s, a moving distance of 80mm, a voltage of 16KV, and spun at ambient temperature to obtain a chemical based on the two fibers. Heterogeneous electrospun fiber membranes.

[0050] The obtained chemically heterogeneous electrospinning fiber membrane was immersed in a 1.5 mg / ml polydimethyldiallyl ammonium chloride aqueous solution, adsorbed and equilibrated for 10 minutes, washed with deionized water for 10 minutes, and dried in the air; Immerse the dried fiber membrane in a 1.5 mg / ml sodium polystyrene sulfonate aqueous solution, absorb and equilibrate for 10 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com