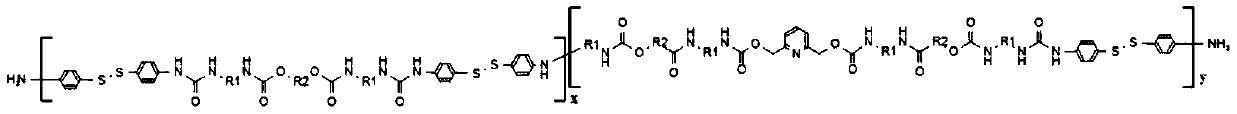

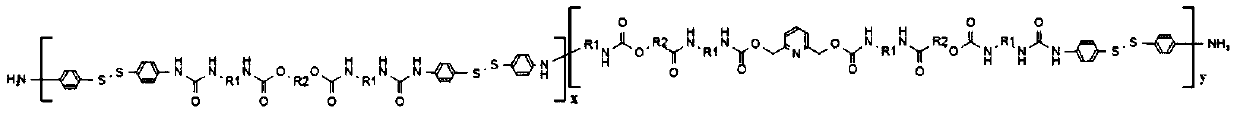

Transparent high strength and high toughness room temperature self-repairing thermoplastic polyurethane urea elastomer and preparation method

A polyurethane urea, high-strength technology, applied in the field of transparent, high-strength, high-toughness room temperature self-healing thermoplastic polyurethane urea elastomer and its preparation, achieving high application value, low activation energy, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

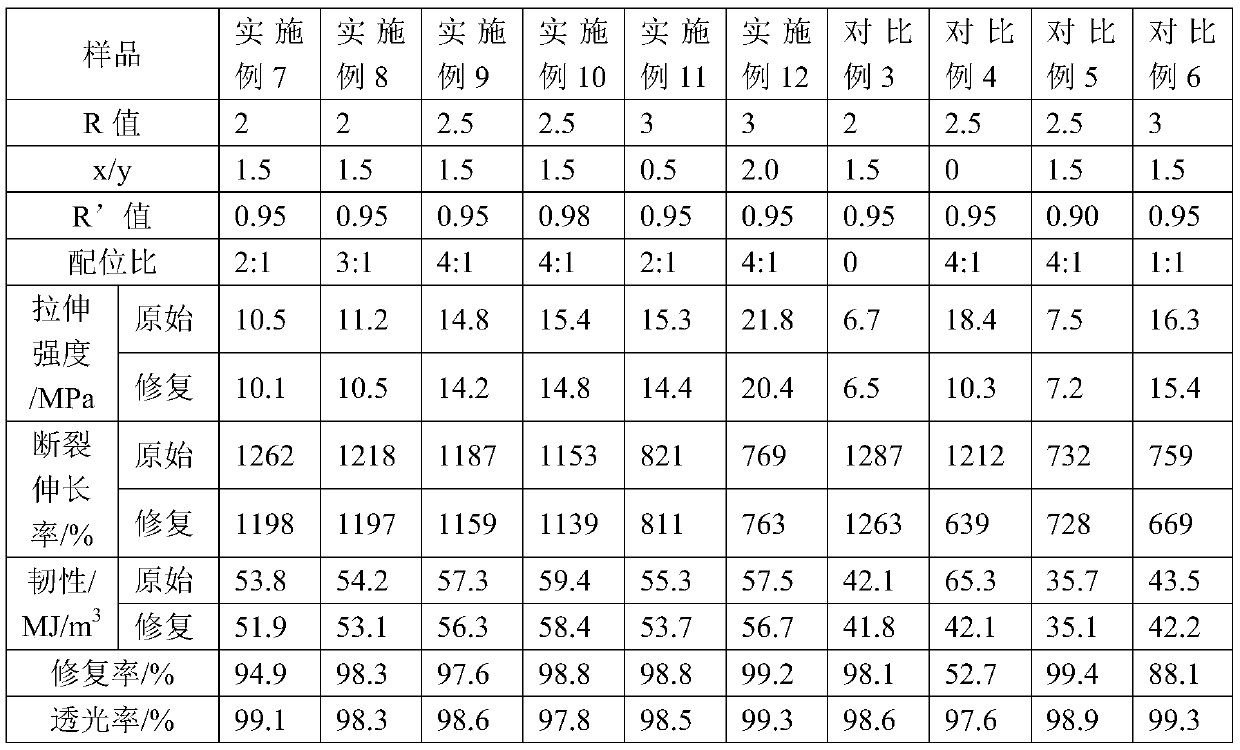

Examples

Embodiment 1

[0043] Step (1): Set the R value to 2.0, put 0.020mol (40.000g) DL2000 into the reactor, raise the temperature to 115°C, keep the vacuum at -0.098MPa and remove water for 1 hour while stirring, then lower the temperature to 95°C , feed nitrogen for protection, drop 0.040mol (8.892g) IPDI, stir and react for 1.5 hours, add 4.000 × 10 -6mol of dibutyltin dilaurate continued to react for 2 hours to obtain an isocyanate group-terminated polyurethane prepolymer, which was protected under nitrogen for further use.

[0044] Step (2): The x / y ratio is set to 1.5, the R’ value is set to 0.95, the coordination ratio is set to 4:1, and 3.800×10 - 3 mol (0.529g) of 2,6-pyridinedimethanol was dissolved in 30mL of N,N-dimethylformamide, and put into the prepolymer obtained in step (1), the temperature was kept at 95°C, protected by nitrogen gas, and reacted for 2 hours After that, input 1.520×10 -2 mol (3.775g) 4,4'-diaminodiphenyl disulfide continued to react for 2 hours, dropped into 0...

Embodiment 2

[0046] Step (1): Set the R value to 2.0, put 0.020mol (40.000g) DL2000 into the reactor, raise the temperature to 115°C, keep the vacuum at -0.098MPa and remove water for 1 hour while stirring, then lower the temperature to 95°C , feed nitrogen for protection, drop 0.040mol (8.892g) IPDI, stir and react for 1.5 hours, add 4.000 × 10 -6 mol of dibutyltin dilaurate continued to react for 2 hours to obtain an isocyanate group-terminated polyurethane prepolymer, which was protected under nitrogen for further use.

[0047] Step (2): The x / y ratio is set to 1.0, the R’ value is set to 0.95, the coordination ratio is set to 4:1, and 4.750×10 - 3 mol (0.661g) of 2,6-pyridinedimethanol was dissolved in 30mL of N,N-dimethylformamide, and put into the prepolymer obtained in step (1), the temperature was kept at 95°C, protected by nitrogen gas, and reacted for 2 hours After that, input 1.425×10 -2 mol (3.539g) 4,4'-diaminodiphenyl disulfide continued to react for 2 hours, dropped into ...

Embodiment 3

[0049] Step (1): Set the R value to 2.0, put 0.020mol (40.000g) DL2000 into the reactor, raise the temperature to 115°C, keep the vacuum at -0.098MPa and remove water for 1 hour while stirring, then lower the temperature to 95°C , feed nitrogen for protection, drop 0.040mol (8.892g) IPDI, stir and react for 1.5 hours, add 4.000 × 10 -6 mol of dibutyltin dilaurate continued to react for 2 hours to obtain an isocyanate group-terminated polyurethane prepolymer, which was protected under nitrogen for further use.

[0050] Step (2): The x / y ratio is set to 1.0, the R’ value is set to 0.95, the coordination ratio is set to 4:1, and 6.333×10 - 3 mol (0.881g) of 2,6-pyridinedimethanol was dissolved in 30mL N,N-dimethylformamide, and put into the prepolymer obtained in step (1), the temperature was kept at 95°C, protected by nitrogen gas, and reacted for 2 hours After that, input 1.267×10 -2 mol (3.146g) 4,4'-diaminodiphenyl disulfide continued to react for 2 hours, dropped into 0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| toughness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com