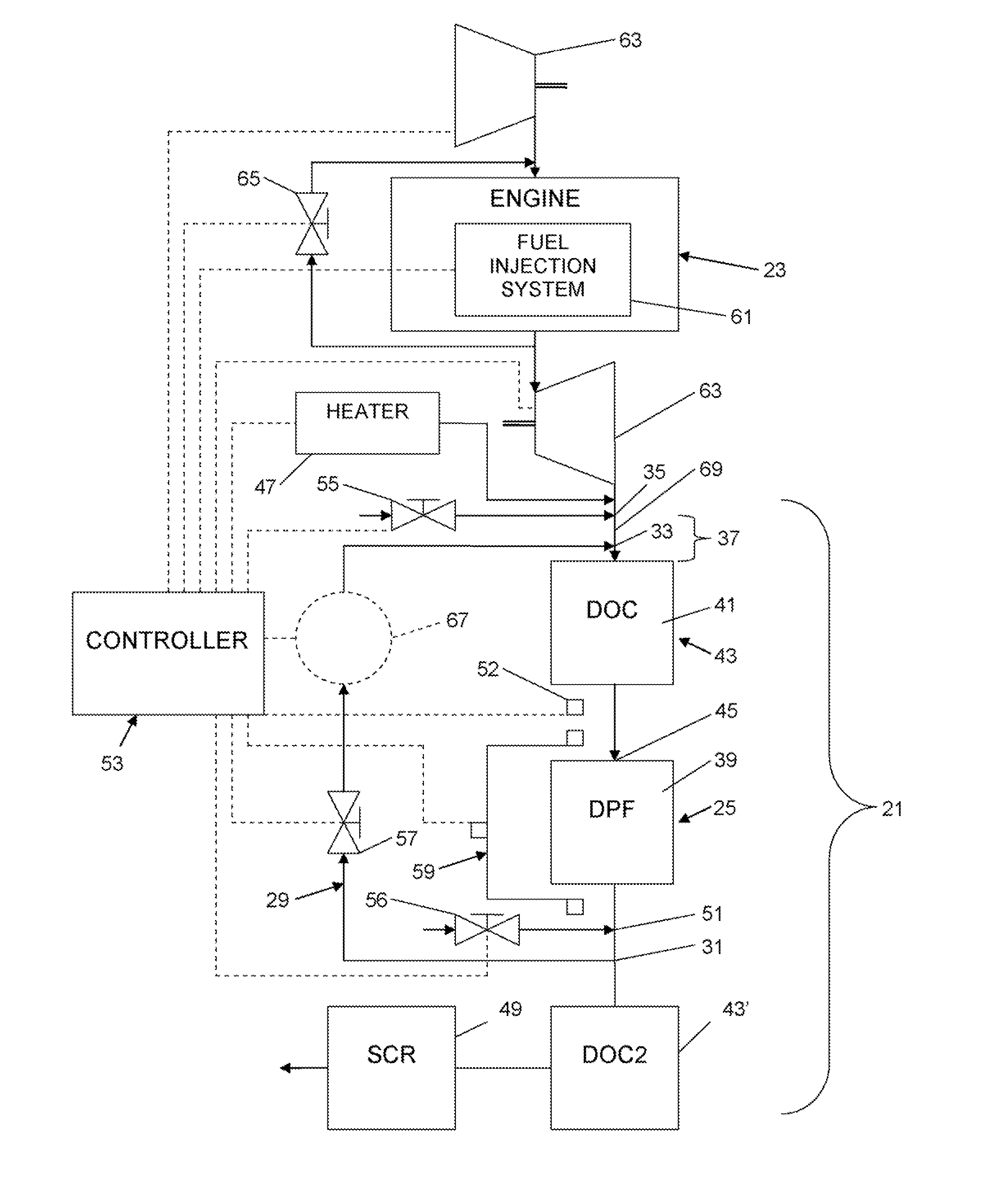

Method and apparatus for no2-based regeneration of diesel particulate filters using recirculated NOX

a technology of nox and diesel particulate filter, which is applied in mechanical equipment, machines/engines, electric control, etc., can solve the problems of o2-based regeneration, inability to guarantee adequate dpf regeneration in all applications, and the requirement to observe the maximum dpf soot loading level, so as to reduce the activation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]The invention shall first be described in general, more theoretical terms, as presently understood by the inventors, and, thereafter, in terms of more specific aspects. The invention is not to be considered to be limited by the theories that are set forth herein to explain the inventors' present understanding of how the invention works, except to the extent that such theories are expressly included in the claims.

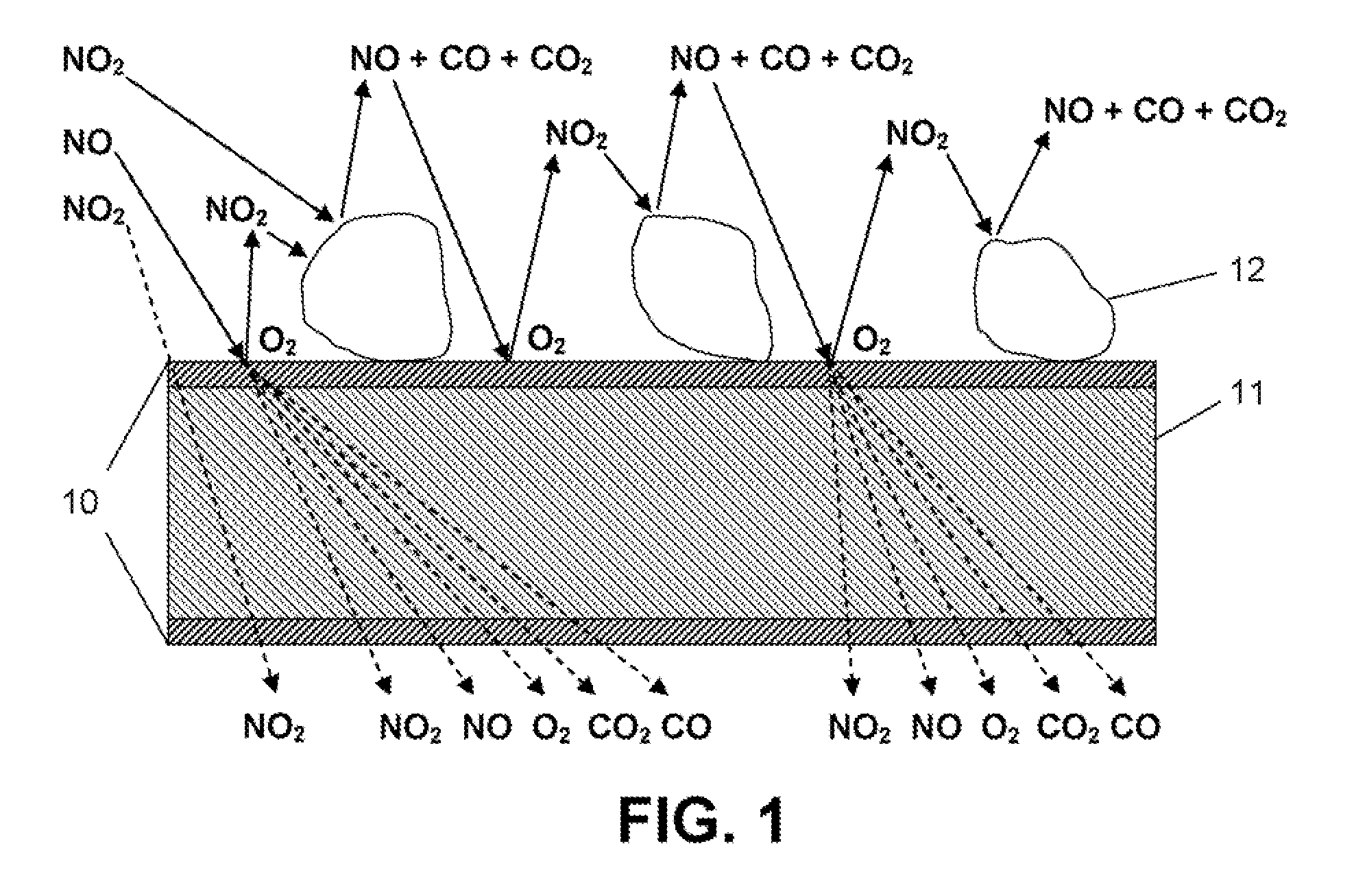

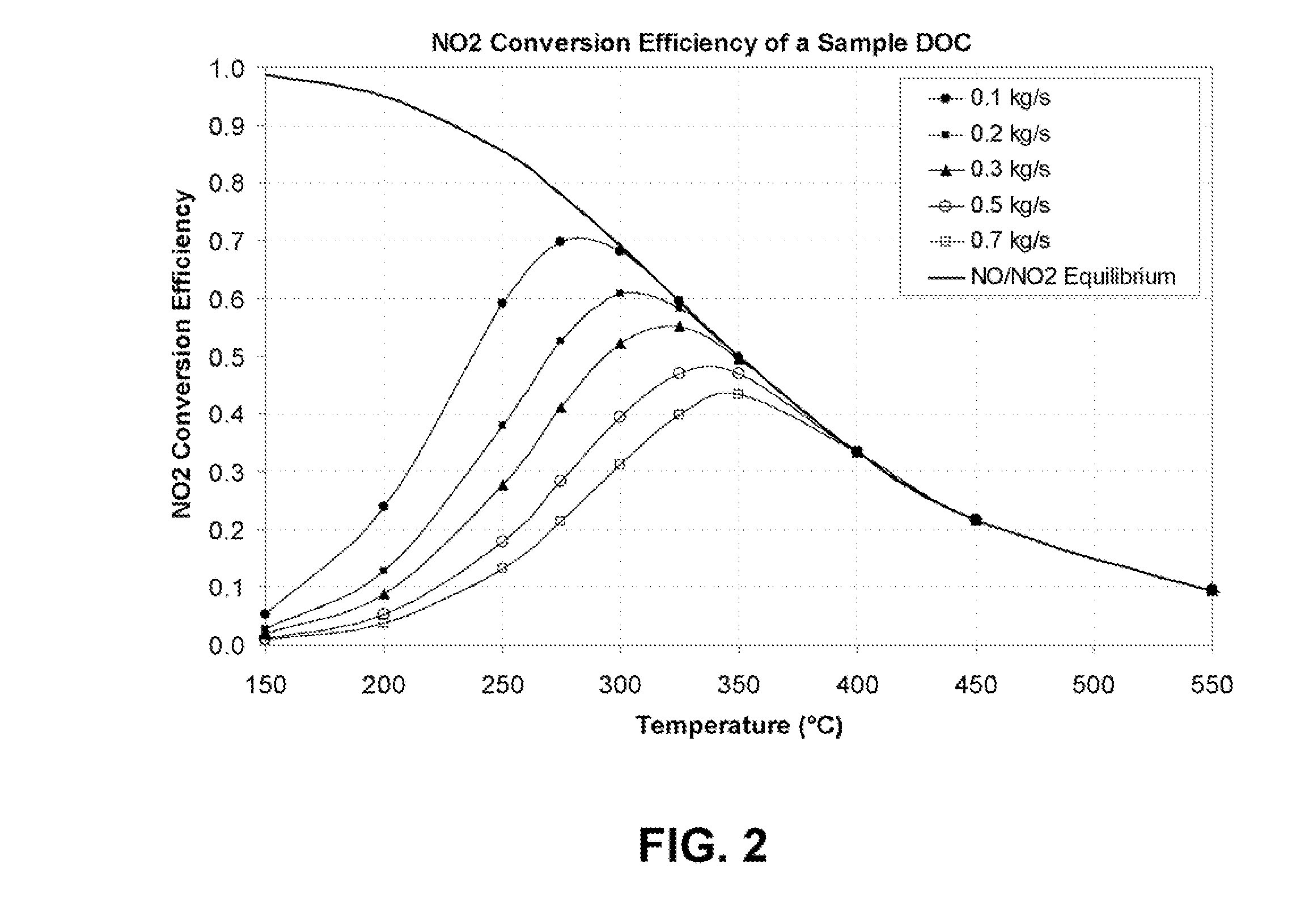

[0020]The inventors recognize that there are two ways in which the reaction rate of the soot in the DPF is limited. The reaction will either be kinetically controlled (due to too low reactant temperature) or diffusion limited (due to too low supply of reactant). Simply stated, the necessary reactants must be supplied and the minimum activation energy for the reaction must be achieved. These conditions may be fulfilled either through active control or achieved passively during normal operation.

[0021]For any type of active regeneration process utilizing active thermal co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com