Oxazinyl carbon-nitrogen polymer, and preparation method and application thereof

A technology of azine-based carbon nitrogen and heptazine-based carbon nitrogen, which is applied in the field of azine-based carbon nitrogen polymers and its preparation, can solve the problems of simple and unreported related reports, achieve the improvement of conduction rate, the raw materials are simple and easy to obtain, and avoid Effects of polluting by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] This embodiment provides an azine-based carbon nitrogen polymer, which is prepared by the following steps:

[0061] Weigh 15.0g of melamine in a crucible, add 30mL of distilled water into the crucible, place the crucible at 25°C and stir for 30 minutes to fully dissolve it, then bake it at 450°C for 4 hours (heating rate: 5°C / min) Naturally cooled to room temperature, ground and collected to obtain a white solid, which is an azine-based carbon nitrogen polymer.

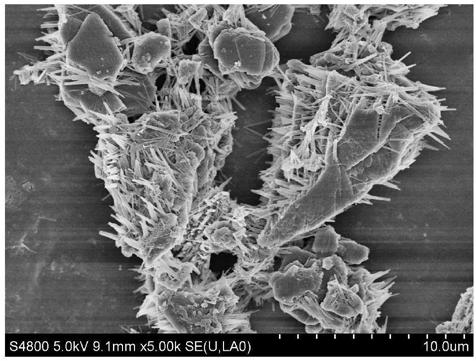

[0062] The azine-based carbon-nitrogen polymer prepared in Example 1 is a rod-shaped material grown on a sheet structure, the rod-shaped length is about 20 microns, the diameter is 55 nm, the carbon-nitrogen ratio is 0.67, and it has photocatalytic activity.

[0063] The elemental analysis results are referring to Table 1, wherein it can be seen that the sample carbon-nitrogen ratio prepared in embodiment 1 is 0.67, and the carbon-nitrogen ratio is lower than theoretical C 3 N 4 0.75, the degree of polymeriza...

Embodiment 2

[0106] Change the roasting time to 2 hours, and all the other preparation processes are the same as in Example 1.

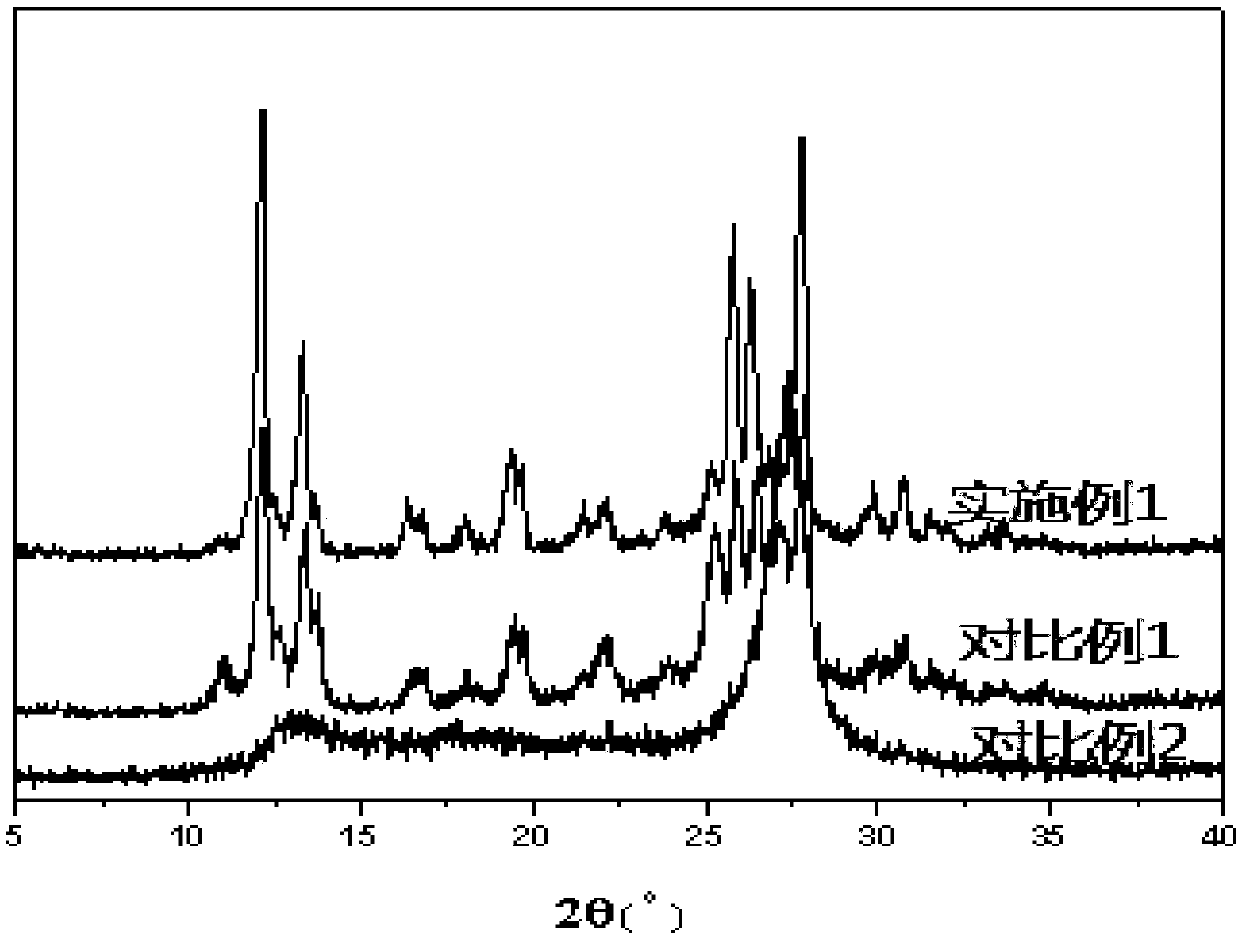

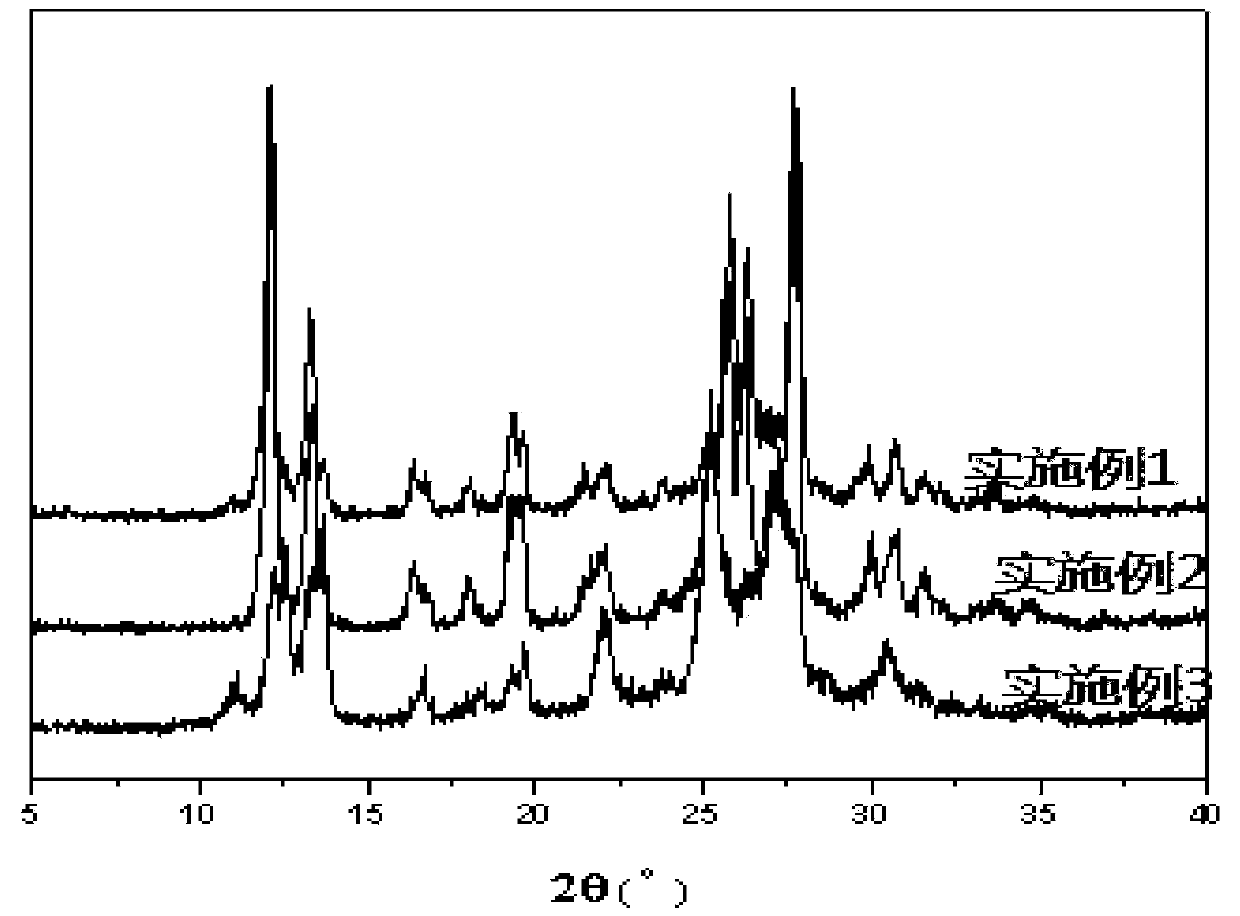

[0107] Figure 1b For the X-ray diffraction (XRD) collection of samples prepared in Examples 1 to 3, as shown in Figure 1b, it shows that the diffraction peaks of the samples prepared in Example 2 are similar to those of melem, indicating that the samples are low Polycarbonate photocatalyst.

[0108] Figure 2f For the scanning electron microscope (SEM) photograph of the prepared sample of embodiment 2, as Figure 2f As shown, it shows that the sample prepared in Example 2 is a material with a rod-shaped structure grown on a sheet structure, but the rod-shaped length is relatively short, about 5 microns.

[0109] Figure 5b The infrared spectroscopic analysis spectrum in the surface shows that the sample prepared in Example 2 is also mixed with carbon-oxygen bonds.

[0110] Figure 6b For the ultraviolet-visible absorption spectrum of the prepared sample of...

Embodiment 3

[0113] Change the roasting time to 6 hours, and all the other preparation processes are the same as in Example 1.

[0114] Figure 1b The X-ray diffraction (XRD) pattern shows that the sample prepared in Example 3 is an oligomeric carbon nitrogen material.

[0115] Figure 2g For the scanning electron microscope (SEM) photo of the prepared sample of embodiment 3, as Figure 2g As shown, it shows that the sample prepared in Example 3 is a rod-like structure.

[0116] Figure 5b The infrared spectrogram shows that the sample prepared in Example 3 incorporates carbon-oxygen bonds, which increases oxygen defects and improves catalytic activity.

[0117] Figure 6b The ultraviolet-visible absorption spectrum shows that the absorbance intensity of the sample prepared in Example 3 is relatively strong.

[0118] Figure 8 It shows that the sample prepared in Example 3 has certain photocatalytic activity.

[0119] Figure 1b For the X-ray diffraction (XRD) collection of sample...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com