Preparation method of metal-organic framework material photocatalyst and application

A metal-organic framework and photocatalyst technology, which is applied in the direction of catalyst activation/preparation, organic compound/hydride/coordination complex catalyst, chemical instrument and method, etc., can solve the problems of high energy consumption and long reaction time, and achieve High degradation rate, short reaction time, widening research field effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

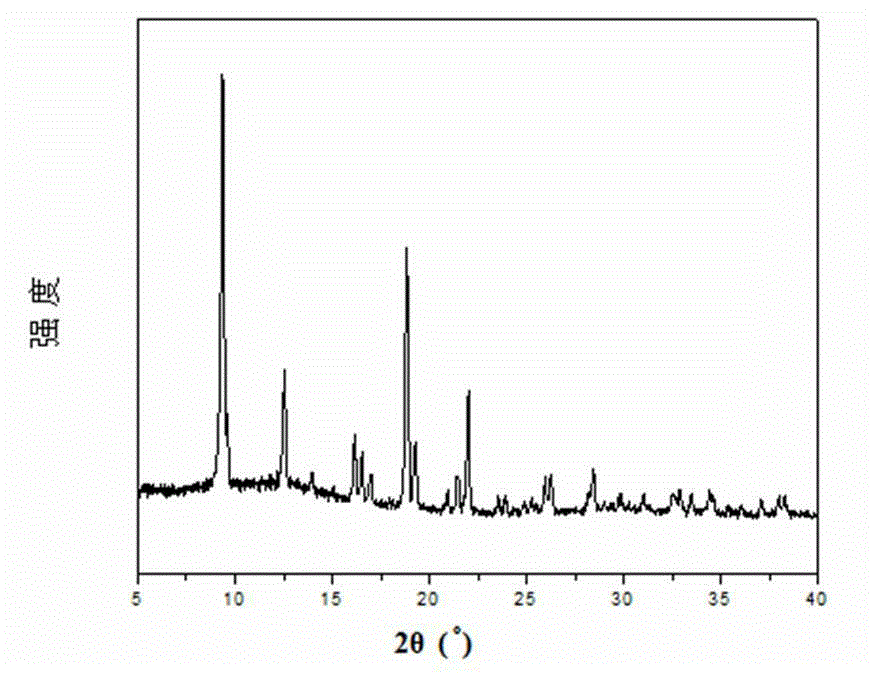

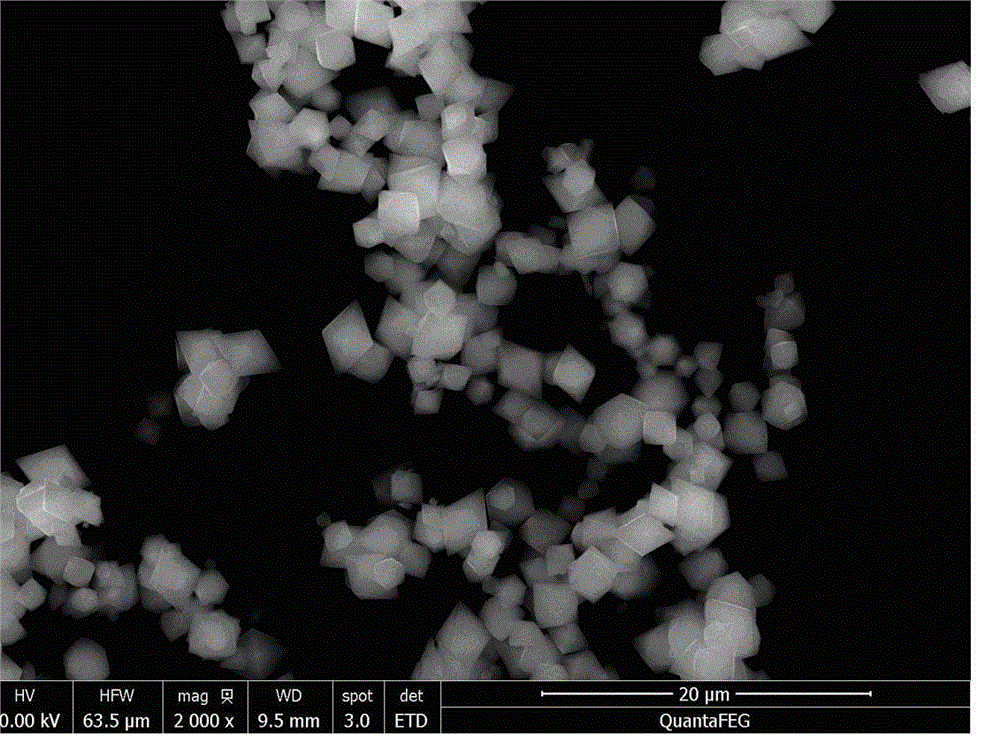

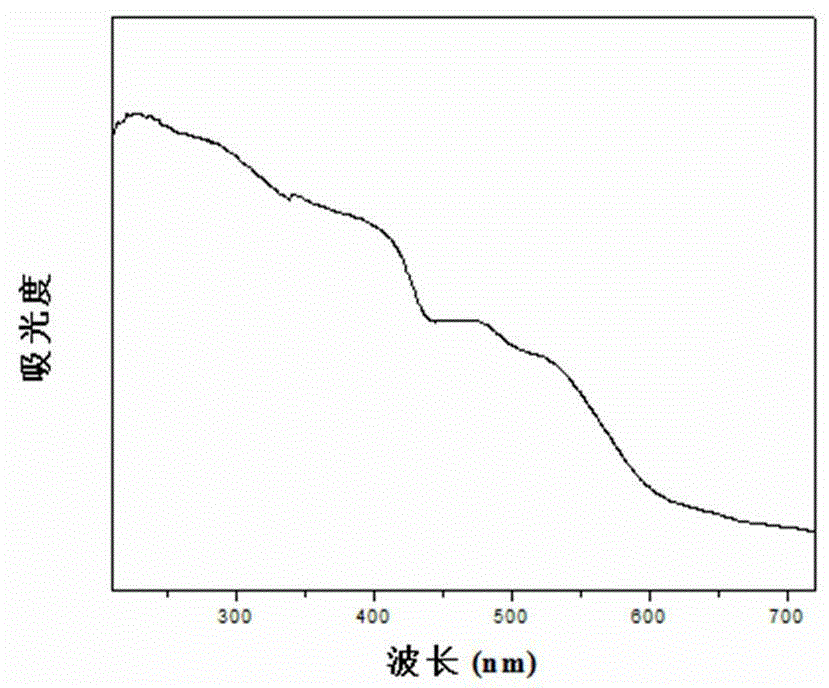

[0021] A method for preparing a metal-organic framework material photocatalyst, comprising the following steps:

[0022] Step 1. Take the organic ligand 1,4-terephthalic acid, dissolve it in N,N-dimethylformamide, stir at room temperature for 5-20 min, and obtain a clear and transparent solution for later use;

[0023] Step 2, adding ferric chloride to the clear and transparent solution obtained in step 1, and stirring at room temperature for 5-20 min to obtain a mixed solution for subsequent use;

[0024] Step 3, add ethanol solution to the mixed solution obtained in step 2, mix evenly, transfer to the reactor, place the reactor in a microwave digestion apparatus, o Reaction at C temperature for 20-50 min, after the reaction is completed, cool and pour off the supernatant to obtain a solid product for subsequent use;

[0025] Step 4, the solid product obtained in step 3 is washed with a mixed solvent of N,N-dimethylsulfoxide-ethanol with a volume ratio of 1:5, and centrifuga...

Embodiment 1

[0031] A method for preparing a metal-organic framework material photocatalyst, comprising the following steps:

[0032] Step 1. Take 0.5125 g of the organic ligand 1,4-terephthalic acid, dissolve it in 30 ml of N,N-dimethylformamide, stir at room temperature for 10 min, and obtain a clear and transparent solution for later use;

[0033] Step 2. Add 0.5000 g of metal iron salt, ferric chloride, to the clear and transparent solution obtained in step 1, and stir for 10 min at room temperature to obtain a mixed solution for subsequent use;

[0034] Step 3. Add ethanol solution to the mixed solution obtained in step 2. The volume ratio of the mixed solution and the ethanol solution is 1:1, mix well, transfer to the reaction kettle, and then place the reaction kettle in a microwave digestion instrument, set the power to 500W , at 100 o Reaction at C temperature for 50 min, after the completion of the reaction, cooling and decanting the supernatant to obtain a solid product for sub...

Embodiment 2

[0039] A method for preparing a metal-organic framework material photocatalyst, comprising the following steps:

[0040] Step 1. Take 0.1543 g of organic ligand 1,4-terephthalic acid, dissolve it in 30 ml of N,N-dimethylformamide, stir at room temperature for 5 min, and obtain a clear and transparent solution for later use;

[0041] Step 2. Add 0.5000 g of metal iron salt, ferric chloride, to the clear and transparent solution obtained in step 1, and stir for 10 min at room temperature to obtain a mixed solution for subsequent use;

[0042] Step 3, add ethanol solution to the mixed solution obtained in step 2, the volume ratio of the mixed solution and the ethanol solution is 1:1, mix evenly, transfer to the reaction kettle, then place the reaction kettle in a microwave digestion instrument, at 80 o React at temperature C for 50 minutes. Set the power of the microwave digestion instrument to 600W for the first 30 minutes and 400W for the last 20 minutes. After the reaction is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com