Preparation method and application of binary intercalation mesoporous g-C3N4@ATP composite photocatalyst

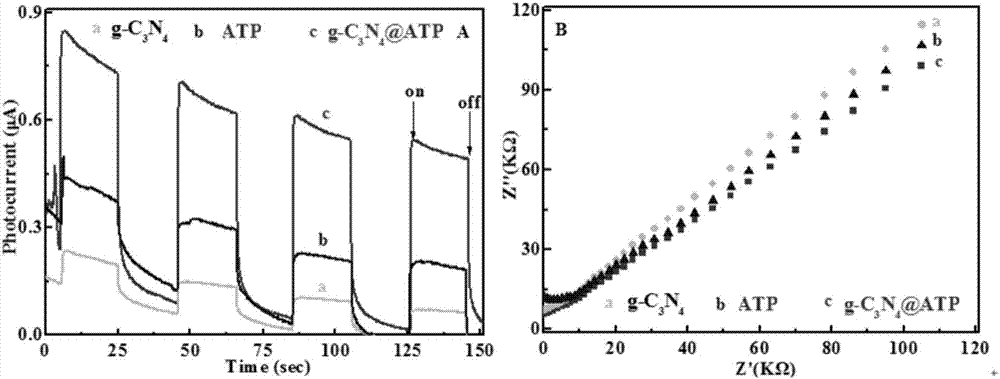

A composite photo-catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of increased drug resistance, loss of sensitivity of pathogenic microorganisms, and loss of treatment of diseases Effect and other issues, to achieve the effect of high degradation rate, simple synthesis, good photocatalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

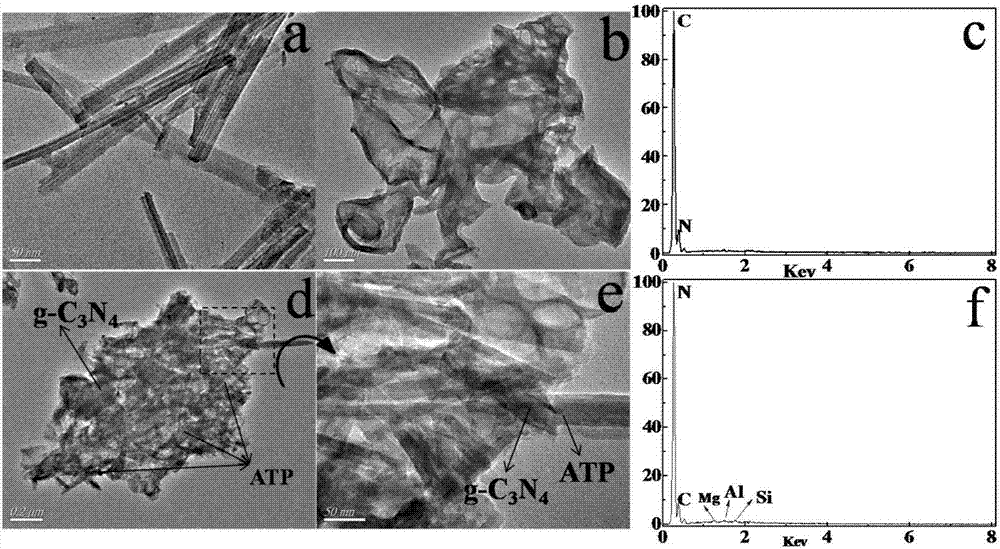

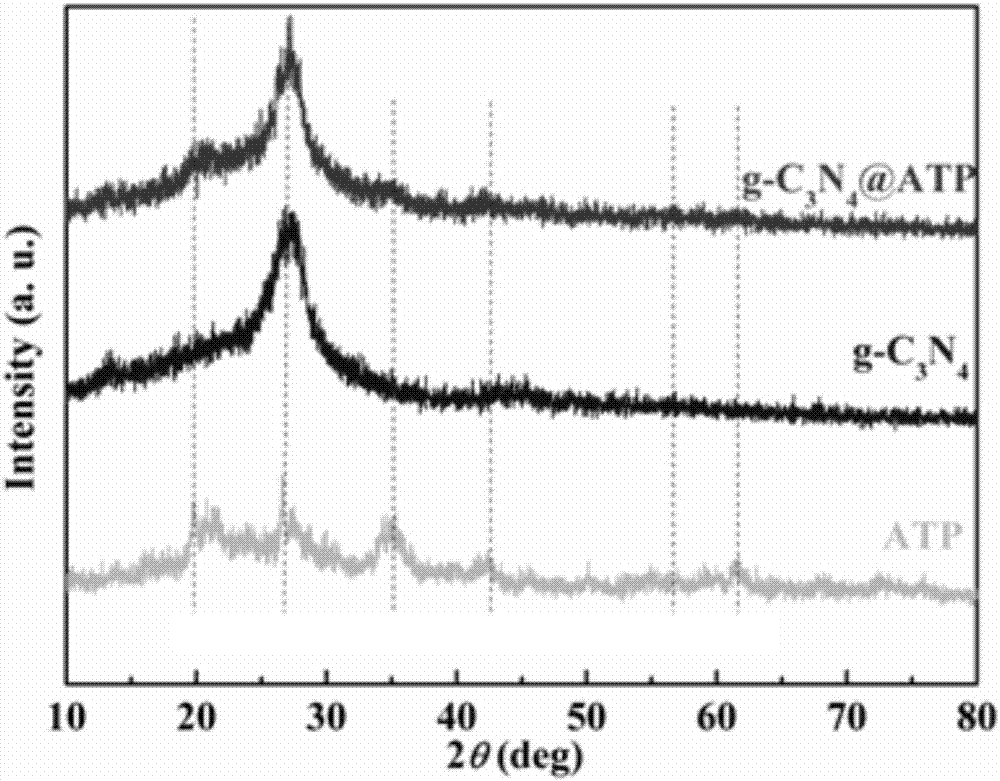

[0022] Step 1, preparation of modified attapulgite (ATP): get 10~20g attapulgite and add to 100~200mL hydrochloric acid (1molL -1 ) solution, sealed and magnetically stirred for 2-3h to disperse evenly, ultrasonicated for 0.5-1h, centrifuged to obtain a solid sample, placed in an oven at a certain temperature, and vacuum-dried for 8h to obtain modified ATP.

[0023] Step 2. Take 0.005g of ATP and disperse it into 20mL of ethanol, then add 5g of urea to dissolve and seal it, magnetic stirring time is 3h, ultrasonic time is 0.5h, and the product is vacuum-dried for 8h. Then the mixture was placed in a crucible and sealed with aluminum foil, and calcined at a high temperature in a muffle furnace at 500°C, and the heating rate was 1.0°C / min. After the temperature of the muffle furnace was cooled to room temperature, the crucible was taken out and the solid sample in the crucible was ground into powder, and then the sample was dried in an oven to obtain yellow ATP-modified g-C 3 N...

Embodiment 2

[0026] Step 1, preparation of modified attapulgite (ATP): get 20g of attapulgite and add to 100mL hydrochloric acid (1mol L -1 ) solution, sealed with magnetic stirring for 3 hours until uniformly dispersed, ultrasonicated for 1 hour, centrifuged to obtain a solid sample, placed in an oven at a certain temperature, and vacuum-dried for 8 hours to obtain modified ATP.

[0027] Step 2. Take 1.0 g of ATP and disperse it into 20 mL of ethanol, then add 5 g of urea to dissolve and seal it, magnetic stirring time is 5 h, ultrasonic time is 2 h, and the product is vacuum-dried for 8 h. The mixture was then placed in a crucible and sealed with aluminum foil, and calcined at a high temperature in a muffle furnace at 500°C with a heating rate of 10°C / min. After the temperature of the muffle furnace was cooled to room temperature, the crucible was taken out and the solid sample in the crucible was ground into powder, and then the sample was put into an oven to dry to obtain yellow ATP-mo...

Embodiment 3

[0030] Step 1, preparation of modified attapulgite (ATP): get 15g attapulgite and add to 150mL hydrochloric acid (1mol L -1 ) solution, sealed magnetic stirring for 1.5h until uniform dispersion, ultrasonication for 0.8h, placed in an oven at a certain temperature and vacuum-dried for 8h to obtain modified ATP.

[0031] Step 2. Take 0.01 g of ATP and disperse it in 20 mL of ethanol, then add 5 g of urea to dissolve and seal it, magnetic stirring time is 4 h, ultrasonic time is 1.5 h, and the product is vacuum-dried for 8 h. Then the mixture was placed in a crucible and sealed with aluminum foil, and calcined at a high temperature in a muffle furnace at 500°C, and the heating rate was 5°C / min. After the temperature of the muffle furnace was cooled to room temperature, the crucible was taken out and the solid sample in the crucible was ground into powder, and then the sample was dried in an oven to obtain yellow ATP-modified g-C 3 N 4 . marked as g-C 3 N 4 @ATP photocatalys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com