Light-driven CO2 reduction method of silver-modified copper-loaded zeolite Ag/Cu-TS-1

A TS-1, cu-ts-1 technology, applied in chemical instruments and methods, chemical/physical processes, catalyst activation/preparation, etc., can solve the problems of low product selectivity and low efficiency, and achieve the inhibition of competitive hydrogen evolution. The effect of reaction, improving stability, good photoelectric catalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

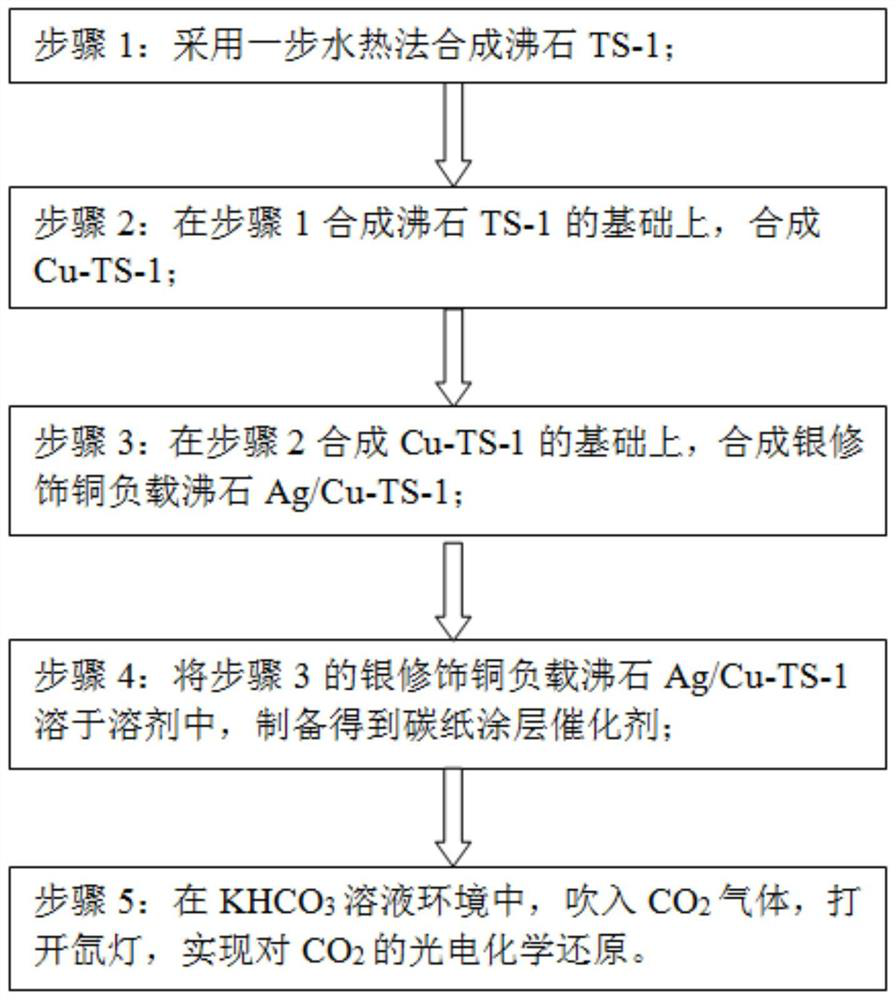

[0038] Light-driven CO of a silver-modified copper-loaded zeolite Ag / Cu-TS-1 2 The restoration method includes the following steps:

[0039] Step 1: Synthesize copper-loaded zeolite Cu-TS-1 by one-step hydrothermal method, specifically as follows:

[0040] Step 1.1: Add 0.1 g Na to 8 ml deionized water 2 CO 3 , then add 14.4g of tetrapropylammonium hydroxide with a purity of 25wt%, stir it with a constant magnetic field at 40°C for 4h, then slowly add 3.9g of H 2 SiO 3 ;

[0041] Step 1.2: Add 0.24g of Ti(SO 4 ) 2 Add 3ml of deionized water dropwise to the solution prepared in step 1.1, stir vigorously at 40°C for 6h, then transfer the solution to a 50mL polytetrafluoroethylene autoclave, and keep at 150°C for 24 hours;

[0042] Step 1.3: Centrifuge the solution after the autoclave reaction in Step 1.2, wash with deionized water three times, and air-dry at 100°C for 8 hours to obtain a solid substance;

[0043] Step 1.4: Calcining the solid material obtained in Step 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com