Application of nano TiO2/CdS composite photocatalyst in normal-temperature degradation of hydrocarbon compounds

A technology of hydrocarbons and composite light, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve good photocatalytic activity and stability, easy collection and recycling, and elimination of HC gas pollutants Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

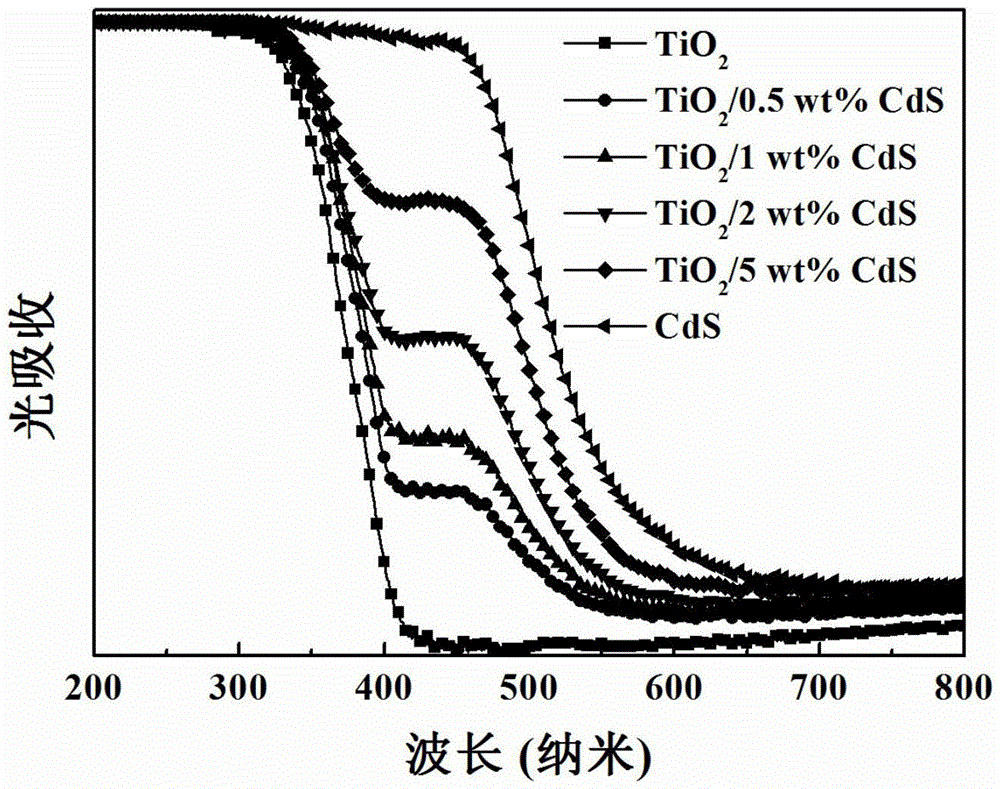

[0019] Example 1: TiO 2 Preparation of / CdS Composite Photocatalyst

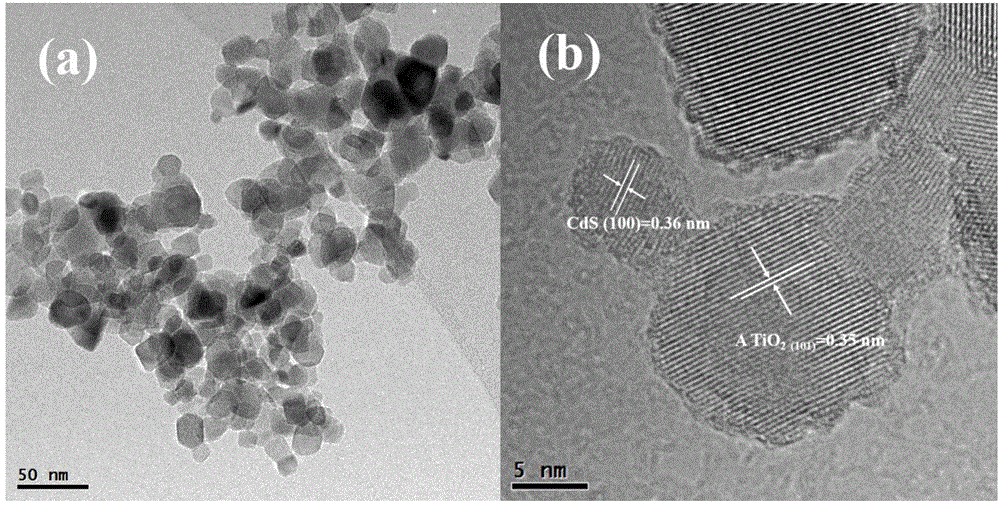

[0020] Add 1 part of tetrabutyl titanate into 10 parts of ethylene glycol with stirring, then add 4 parts of citric acid into the above ethylene glycol, and continue stirring to form a sol. Heat the sol to 523K to form a xerogel, transfer the xerogel to an alumina crucible, place it in a muffle furnace for heat treatment at 823K for 10 hours, and obtain TiO 2 Nano powder, the powder is ground for use.

[0021] 0.108g of CdCl 2 2.5H 2 O and 0.036g of thiourea were dissolved in 90mL of ethanol, heated and magnetically stirred, and the temperature of the solution was controlled at 333K. Dissolve 0.03 g of sodium hydroxide in 30 mL of absolute ethanol, then quickly inject the sodium hydroxide ethanol solution into the CdCl 2 2.5H 2 In the mixed solution of O and thiourea, continue stirring and heating at 333K for 24 hours, and then naturally cool to room temperature. The precipitate was collected by centr...

Embodiment 2

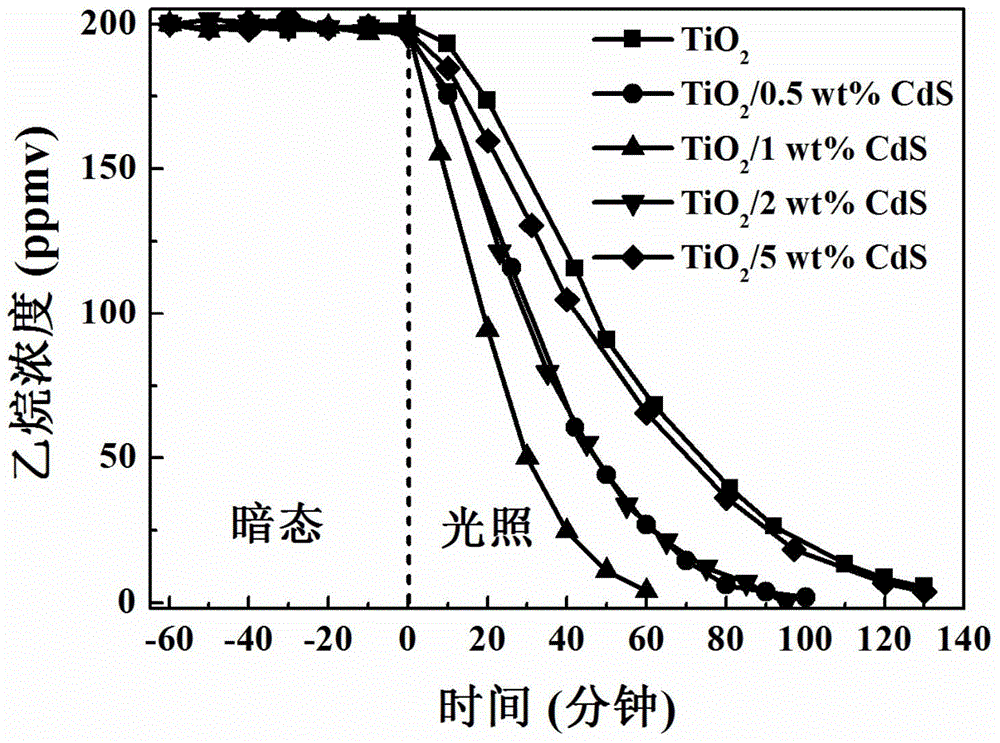

[0023] Example 2: Fixed bed photocatalytic degradation of ethane gas

[0024] The photocatalytic performance test of the photocatalyst fixed bed degrading ethane gas of the present invention is carried out under normal temperature and simulated sunlight. The experimental process is as follows:

[0025] Weigh respectively the TiO prepared in Example 1 2 / CdS composite photocatalyst 0.15g, spread to the bottom of the photoreactor with a volume of 450mL, and seal the reactor. Inject 90 μL of high-purity ethane gas into the photoreactor with a gas microextractor. Keep the reactor away from light for 1 hour, the gas reaches the equilibrium of adsorption and desorption, and then turn on the 300WXe light source. Samples were taken every 10 minutes, and a gas chromatograph was used to detect changes in the concentration of ethane gas in the reactor.

[0026] Test results such as image 3 As shown, under simulated solar irradiation, TiO 2 / CdS composite photocatalysts exhibit exc...

Embodiment 3

[0027] Example 3: Fixed bed photocatalytic degradation of ethylene gas

[0028] The photocatalytic performance test of the photocatalyst fixed bed degrading ethylene gas of the present invention is carried out under normal temperature and simulated sunlight. The experimental process is as follows:

[0029] Take by weighing the TiO prepared in embodiment 1 2 / 1wt%CdS composite photocatalyst 0.15g, spread to the bottom of a photoreactor with a volume of 450mL, and seal the reactor. Inject 90 μL of high-purity ethylene gas into the photoreactor with a gas microextractor. Keep the reactor away from light for 1 hour, the gas reaches the equilibrium of adsorption and desorption, and then turn on the 300WXe light source. Samples were taken every 10 minutes in the dark state and every 5 minutes in the light condition, and gas chromatography was used to detect the change of ethylene gas concentration in the reactor.

[0030] Test results such as Figure 4 As shown, under simulated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com