Rh/CoO nanometer catalyst, and preparation method and application thereof

A nano-catalyst and h-atom technology, which is applied in the preparation of carbon monoxide reaction, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of difficult separation, low stability, and detachment of homogeneous catalysts, and achieve excellent catalytic selectivity , high catalytic activity and catalytic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

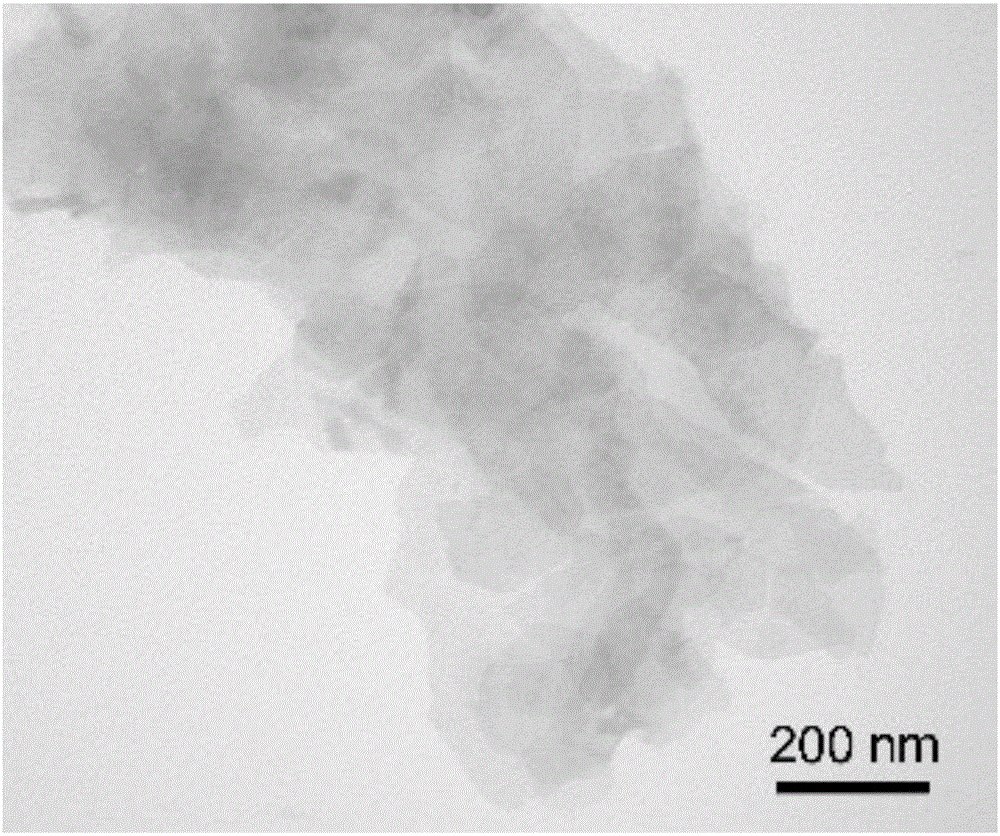

[0036] The preparation method of the above-mentioned Rh / CoO nano-catalyst that the present invention also proposes comprises the following steps: mixing CoO flakes with a two-dimensional crystal structure and deionized water to obtain a mixed solution A; adding sodium hexachlororhodium solution to the mixed solution A Mix evenly to obtain a mixed solution B; stir the mixed solution B at room temperature, wash, and vacuum dry to obtain a Rh / CoO nano-catalyst.

Embodiment 2

[0038] The preparation method of the above-mentioned Rh / CoO nano-catalyst proposed by the present invention includes the following steps: mixing CoO flakes with a two-dimensional crystal structure and deionized water to obtain a mixed solution A, CoO flakes with a two-dimensional crystal structure and deionized water The mass-to-volume ratio (mg / mL) of the mixture is 102:9; the sodium hexachlororhodium solution with a concentration of 5.5 mg / mL is added to the mixed solution A and mixed evenly to obtain the mixed solution B, the sodium hexachlororhodium solution and deionized water The volume ratio is 0.22:9; the mixed solution B was magnetically stirred at room temperature for 3.5 hours, washed, and dried in vacuum to obtain the Rh / CoO nano-catalyst.

[0039] The preparation method of CoO flakes with a two-dimensional crystal structure is as follows: mix cobalt acetylacetonate, ethylene glycol, and deionized water at room temperature, carry out hydrothermal reaction after stir...

Embodiment 3

[0041] The preparation method of the above-mentioned Rh / CoO nano-catalyst proposed by the present invention includes the following steps: mixing CoO flakes with a two-dimensional crystal structure and deionized water to obtain a mixed solution A, CoO flakes with a two-dimensional crystal structure and deionized water The mass-to-volume ratio (mg / mL) is 95:12; In mixed solution A, add the sodium hexachlororhodium solution that concentration is 5mg / mL and mix uniformly to obtain mixed solution B, the sodium hexachlororhodium solution and deionized water The volume ratio is 0.25:8; the mixture B is stirred at room temperature for 5 hours, and the stirred material is centrifuged at a centrifugal speed of 11,000 rpm for 5 minutes, and the centrifuged product is ultrasonically washed with a polar solvent for 1 minute. Then repeat the above steps of centrifugal separation and washing, and vacuum dry at 52° C. to obtain the Rh / CoO nano-catalyst.

[0042]The preparation method of CoO f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com