Method for intercalating and stripping two-dimensional crystal titanium carbide nano material by using ammonia water

A technology of two-dimensional crystals and nanomaterials, applied in nanotechnology and other directions, can solve the problems of high harm of organic matter and low intercalation efficiency, and achieve the effects of low cost, high intercalation efficiency and increased specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

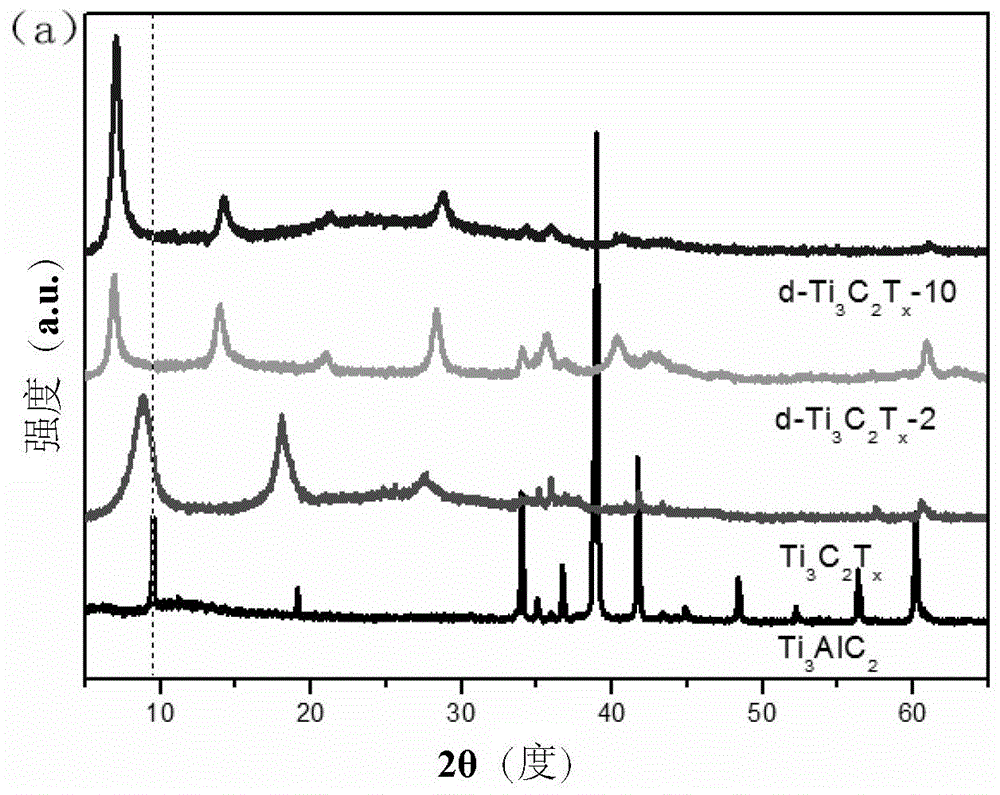

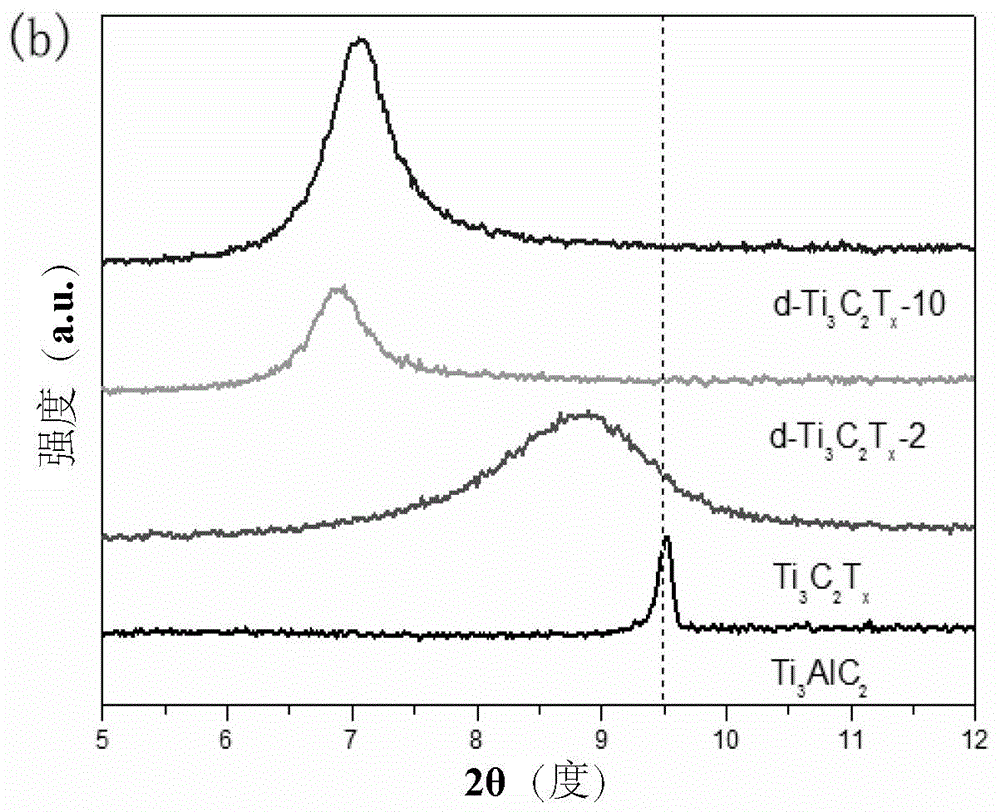

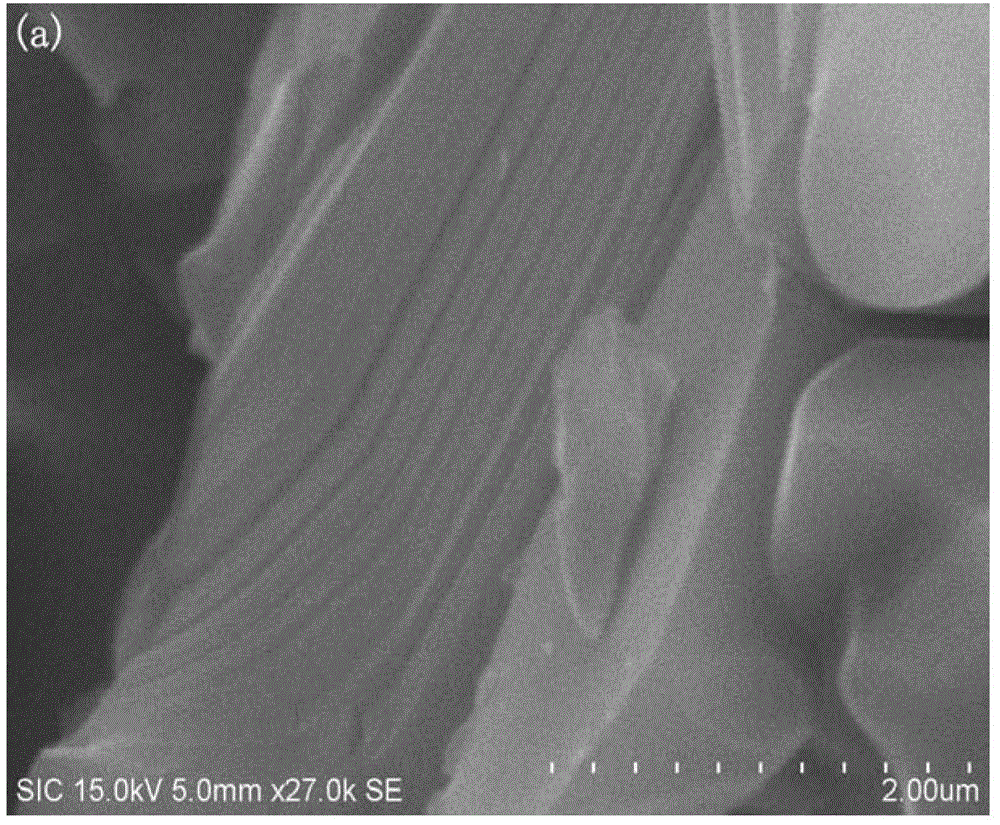

[0033] TiH 2 , TiC, and Al powders were weighed at a molar ratio of 1:2:1.1, and ball milled for 12 hours to make them evenly mixed. Using a vacuum tube furnace, using high-purity argon as a protective gas, sintering at 1400 ° C for 2 hours to prepare high-purity Ti 3 AlC 2 The bulk material is finally ground into a 325 mesh powder. Ti obtained by grinding 8g 3 AlC 2 For powder, add 320ml of HF with a concentration of 49%, react at 60°C for 24h, wash the reaction product with deionized water and absolute ethanol until the pH of the supernatant is nearly neutral, and dry it in vacuum at 80°C to obtain the original two-dimensional crystal Titanium carbide nanomaterial Ti 3 C 2 T x .

[0034] Weigh 5g of prepared Ti 3 C 2 T x Add 100ml of ammonia water with a mass fraction of 25% to 28%, and use a high-speed shearing machine at a speed of 6000 revolutions per minute to treat Ti 3 C 2 Tx was intercalated and exfoliated for 2 hours to obtain a two-dimensional crystal t...

Embodiment 2

[0036] TiH 2 , TiC, and Al powders were weighed at a molar ratio of 1:2:1.1, and ball milled for 12 hours to make them evenly mixed. Using a vacuum tube furnace, using high-purity argon as a protective gas, sintering at 1400 ° C for 2 hours to prepare high-purity Ti 3 AlC 2 The bulk material is finally ground into a 325 mesh powder. Ti obtained by grinding 8g 3 AlC 2 Powder, add 320ml of HF with a concentration of 49%, react at 60°C for 24h, wash the reaction product with deionized water and absolute ethanol until the pH of the supernatant is nearly neutral, and dry it in vacuum at 80°C to obtain the original two-dimensional Crystalline Titanium Carbide Nanomaterial Ti 3 C 2 T x .

[0037] Weigh 5g of prepared Ti 3 C 2 T x Add 100ml of ammonia water with a mass fraction of 25% to 28%, and use a high-speed shearing machine at a speed of 6000 revolutions per minute to treat Ti 3 C 2 Tx was intercalated and exfoliated for 10 hours to obtain a two-dimensional crystal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com