Method for preparing semiconductor nanocrystals by liquid phase ablation of femtosecond laser microchannel

A technology of femtosecond laser and microfluidic channel, which is applied in the direction of laser welding equipment, nanotechnology, chemical instruments and methods, etc., can solve the problems that nanoparticles are easy to agglomerate, so as to avoid amorphous decomposition products, avoid agglomeration effect, avoid Oxidized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

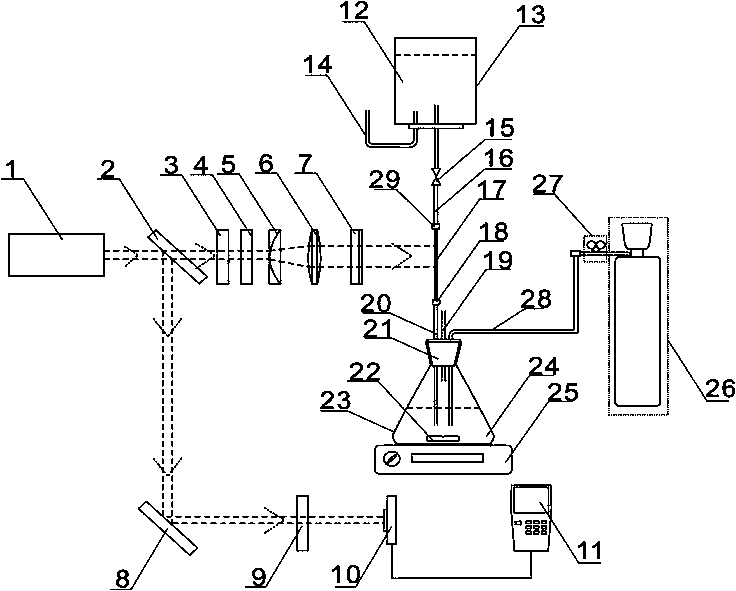

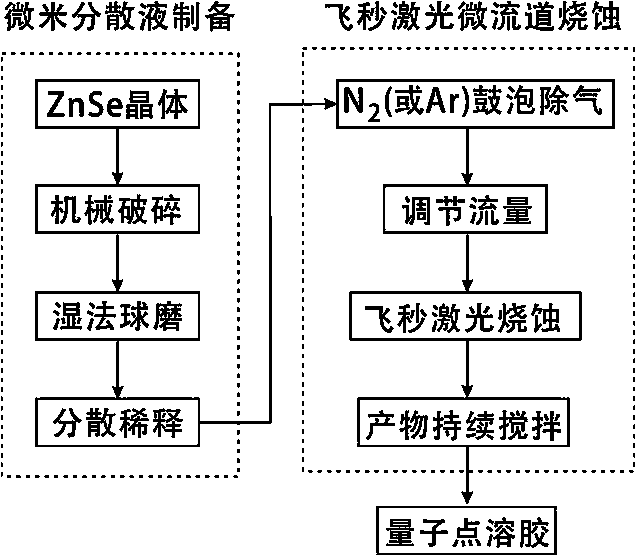

[0036] A method for preparing semiconductor nanocrystals using femtosecond laser microfluidic liquid phase ablation described in this embodiment is as follows: figure 1 The shown device, process steps are as follows:

[0037] (1) Preparation of target material micron particle dispersion

[0038] The zinc selenide polycrystalline block with a purity of 99.99% is first mechanically crushed into particles with a particle size of less than 3 mm, and then an appropriate amount of particles is put into a 100 mL ball mill jar, a small amount of distilled water is added, and the speed is set at about 600 r / min Wet milling is carried out, and the ball milling time is about 6-8 h. After the sample is cooled, wash out the suspension of micron particles obtained after wet grinding, and dilute the suspension for use;

[0039] (2) Construction of microfluidic channel system

[0040] Fill the zinc selenide micron particle distilled water dispersion 12 with a concentration of about 0.5 mg / ...

Embodiment 2

[0046] The method for preparing semiconductor nanocrystals by femtosecond laser microchannel liquid phase ablation described in this example differs from Example 1 in that the target material used in step (1) is chromium-doped zinc selenide (Cr:ZnSe ) crystal; the diameter of the microchannel in step (2) is about 200 μm, and the dispersion liquid used in the collection bottle 23 is distilled water; the single pulse energy of the femtosecond laser in step (3) is about 1.0mJ, and the appearance of the obtained doped nanocrystal is It is a spherical nanoparticle with a particle size of about 10-100 nm. A scanning electron microscope photograph of the product is attached Figure 4 shown.

Embodiment 3

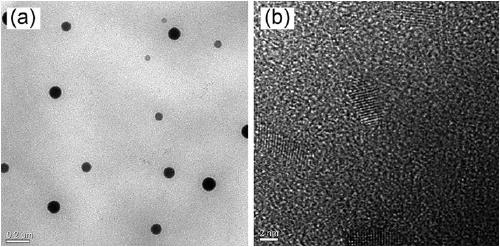

[0048] The method for preparing semiconductor nanocrystals by femtosecond laser microchannel liquid phase ablation described in this example differs from Example 1 in that absolute ethanol is used as the dispersion in step (1); The concentration of zinc selenide microparticles is about 0.25 mg / mL, the dispersion used in the collection bottle 23 is absolute ethanol, and the nitrogen gas cylinder 26 is closed; the single pulse energy in step (3) is 0.8 mJ, and the final product obtained is Zinc selenide nanoparticles coated with a thin layer of amorphous carbon on the surface, spherical in appearance, with a particle size of about 20-100 nm. The transmission electron microscope photograph of its product is attached as Figure 5 As shown in (a), the cladding layer outside the spherical nanocrystals can be seen from the figure. The high-resolution transmission electron microscope photos of the nanocrystals are attached Figure 5 (b) shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com