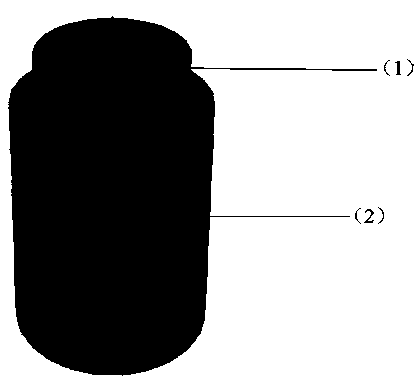

Carbon-coated MnOx nano energy storage material with one-dimensional core-shell structure and preparation method thereof

A technology of shell-core structure and energy storage material, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems that affect the application and development of manganese oxide materials, cannot effectively eliminate cycle performance, and have limited specific surface area of manganese oxide materials. , to achieve good cycle performance, prevent agglomeration effect, high capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Weigh 1.64g of manganese acetate pentahydrate, 1.59g of potassium persulfate, and 2.47g of ammonium nitrate into 10ml, 20ml, and 10ml of deionized water, respectively, sonicate for 10min, mix the solution and sonicate for 10min, and transfer to 60ml of water Thermal reaction kettle, placed in an oven for heat treatment at 140°C for 12h, cooled, washed with deionized water and alcohol in sequence, and dried in an oven at 50°C for 24h to obtain MnO 2 Nanowires; figure 2 for MnO 2 SEM images of nanowires;

[0024] 2) Weigh 0.7g PVP and dissolve it in 20ml ethanol, stir to a uniform solution, then weigh 0.5g MnO in step 1) 2 The nanowires were dispersed into PVP ethanol solution, ultrasonicated for 2 hours, filtered and dried for 12 hours, and the MnO distributed in PVP could be obtained. 2 Nanowires; image 3 MnO distributed in PVP 2 SEM images of nanowires;

[0025] 3) Weigh 0.8g of MnO distributed in PVP in step 2) 2 The nanowires are placed in a tube furnace ...

Embodiment 2

[0027] 1) Weigh 2.45g of manganese acetate pentahydrate, 2.38g of potassium persulfate, and 2.44g of ammonium nitrate into 10ml, 30ml, and 10ml of deionized water, respectively, and mark them as A, B, and C respectively. Ultrasound A, B, and C Mix after 10 minutes, transfer to an 80ml hydrothermal reaction kettle, place in an oven for heat treatment at 120°C for 12h, cool, wash with deionized water, alcohol, deionized water, and alcohol four times in sequence, and place in an oven at 75°C Dry for 24h to get MnO 2 Nanowires;

[0028] 2) Dissolve 0.8g of PVP in 25ml of ethanol, stir for 1h, then weigh the MnO in step 1) 2 Disperse 0.7g of nanowires into the PVP ethanol solution, sonicate for 2h and then let it stand for 1h, filter and dry to obtain MnO distributed in PVP 2 Nanowires;

[0029] 3) Weigh 1.0g of MnO distributed in PVP in step 2) 2 The nanowires are placed in a tube furnace under the protection of nitrogen, heat-treated at 550°C for 3 hours, and cooled to obtain...

Embodiment 3

[0031] 1) Dissolve 2mmol of manganese acetate pentahydrate, 2mmol of potassium persulfate, and 3mmol of ammonium nitrate into 20ml, 35ml, and 15ml of deionized water respectively, mix them after ultrasonic treatment for 10 minutes, and transfer them to a 100ml hydrothermal reaction kettle after ultrasonic treatment for 10 minutes. Heat treatment in an oven at 160°C for 12h, after cooling, wash with deionized water and alcohol in turn, and then dry in an oven at 50°C for 48h to obtain MnO 2 Nanowires;

[0032] 2) Dissolve 1.2g of PVP in 40ml of ethanol, then take the MnO in step 1) 2 Nanowire structure material 0.8g, dispersed in it under the condition of stirring, sonicated for 2h, filtered and dried to obtain MnO distributed in PVP 2 Nanowires;

[0033] 3) Distribute MnO in PVP in step 2) 2 The nanowires are heat-treated at 600°C for 3 hours in a tube furnace under an Ar atmosphere, and after cooling to room temperature, the one-dimensional core-shell structure carbon-coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com