Epitaxial preparation method of gallium nitride LED

A technology of gallium nitride and gallium nitride layer is applied in the field of new quantum well preparation, which can solve problems such as the reduction of luminous efficiency, and achieve the effect of improving the leakage current with the increase of current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

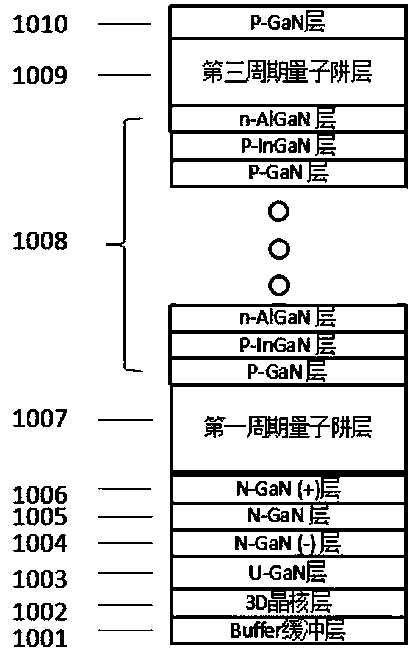

[0044] Please refer to the attached figure 1 , which shows the structural diagram of the gallium nitride-based blue LED described in this embodiment, the growth wavelength of the gallium nitride-based blue LED structure is 465nm, and the specific steps are as follows:

[0045] 1. The temperature of the MOCVD reaction chamber is raised to 560°C, the pressure is 550torr, and trimethylgallium (160ml / min) and NH3 are introduced at the same time for 3.5 minutes, and the reaction occurs to form a 28nm GaN buffer layer 1001 layer;

[0046] 2. Then set the temperature to 1060°C for 9 minutes and drop the pressure to 500torr to make the buffer layer react and form nuclei islands; maintain the temperature at 1060°C and the pressure to 500torr, and inject trimethylgallium (200ml / min) and ammonia gas (30l / min) for a total of 30 minutes, so that the small islands of crystal nuclei grow laterally, and finally the islands merge with the islands; a two-dimensional crystal layer 1002 is forme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com