Spring-internal compression buffer oil cylinder

A buffer oil cylinder and built-in spring technology, which is applied in the hydraulic field, can solve the problems of non-cylindrical dimensions, high processing quality requirements, and high cost of welded components of the cylinder body, so as to avoid poor sealing, low manufacturing cost, and easy debugging and installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

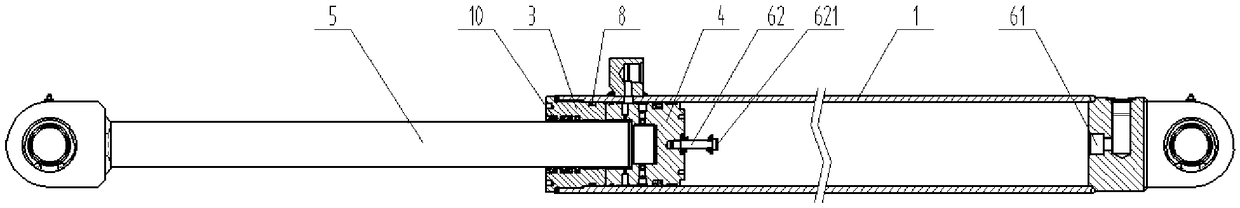

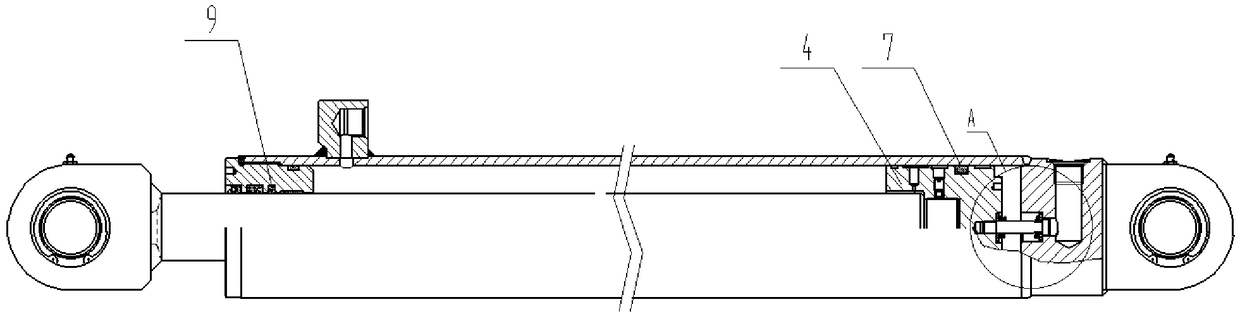

[0022] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

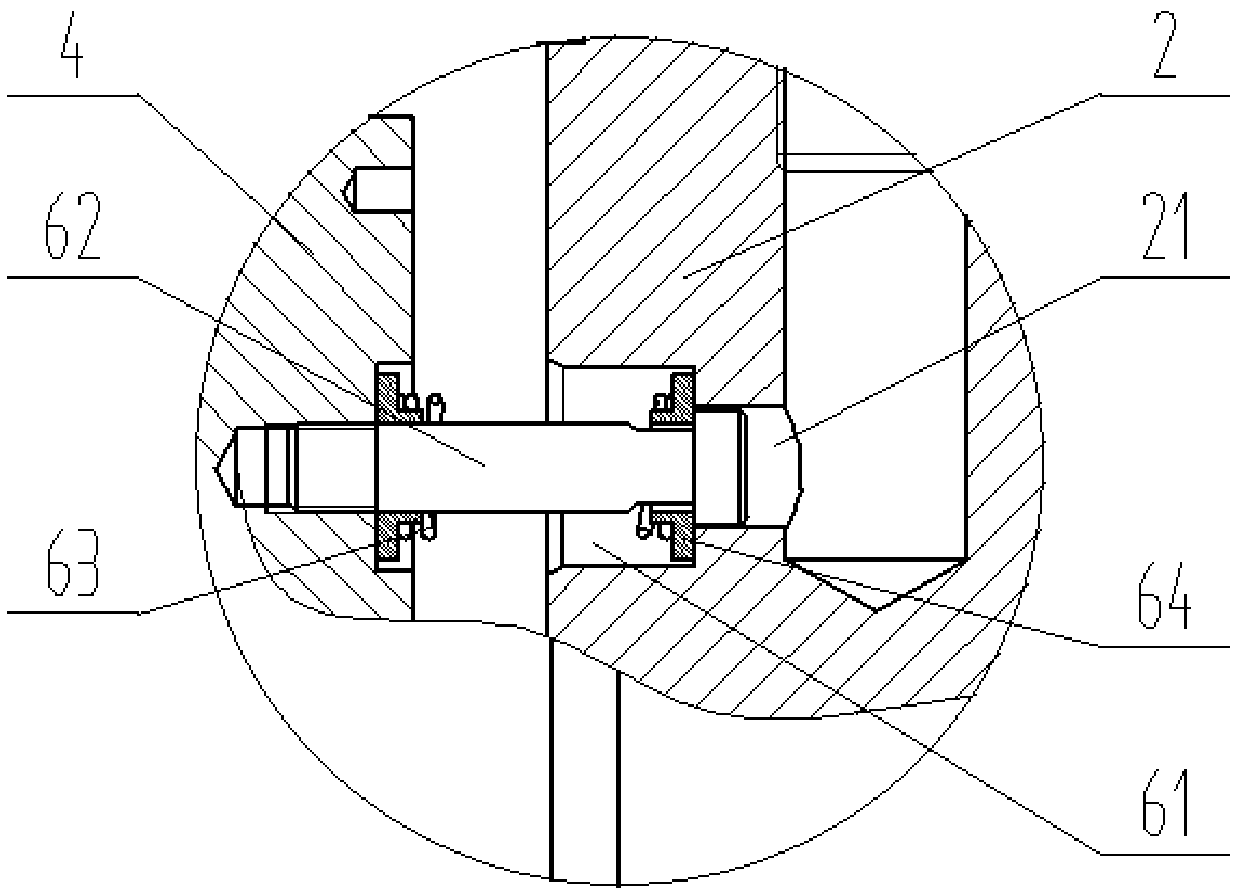

[0023] as attached figure 1 to attach Figure 5 As shown, a built-in spring compression buffer oil cylinder includes a cylinder body, a cylinder rear cover 2, a cylinder front cover 3, a piston 4, a piston rod 5 and a buffer device, and the cylinder body 1 corresponds to the cylinder rear cover 2 and the cylinder front cover 3 respectively. Connected, the piston rod 5 is located in the cylinder body 1, the piston 4 cooperates with the piston rod 5, and an oil outlet 21 is also provided in the oil cylinder rear cover 2.

[0024] The buffer device includes a stepped hole 61, a buffer rod 62, a spring 63 and two spring positioning seats 64. The head end of the buffer rod 62 is fixed at the center of the front end of the piston 4, and a cylindrical stopper 621 is provided at the end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com