High-durability single-wave-line speed reduction bearing

A deceleration bearing and durability technology, applied in the field of deceleration bearings, can solve the problems of reduced transmission efficiency and transmission accuracy, shortened bearing service life, and increased equipment use costs, etc., to reduce friction loss, increase service life, and increase transmission power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

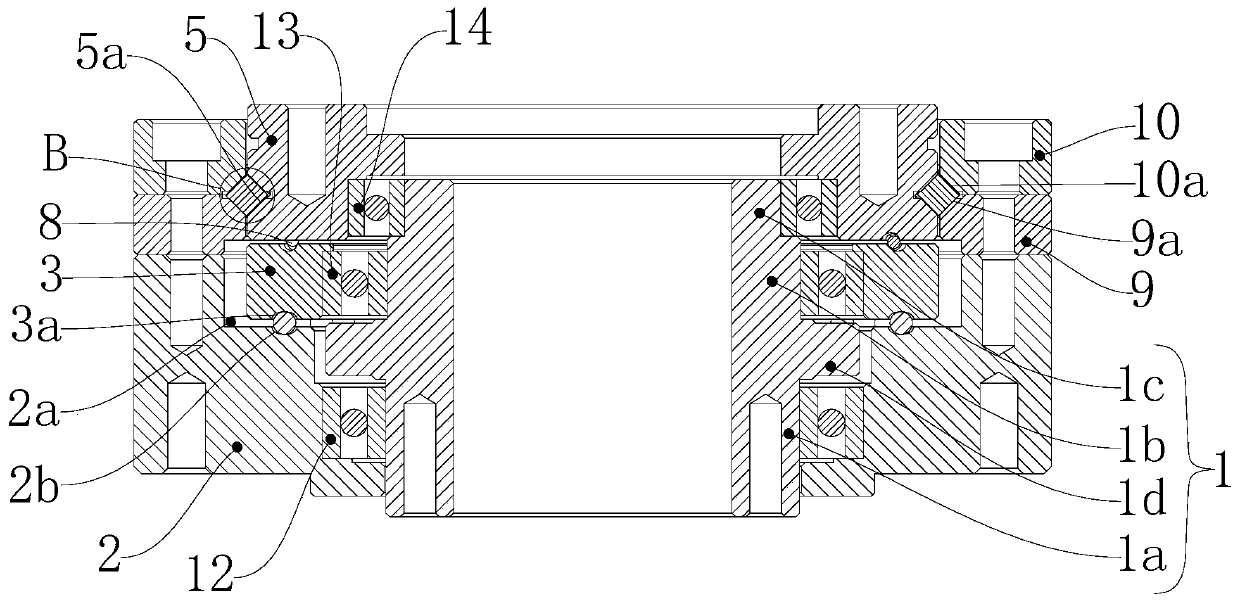

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

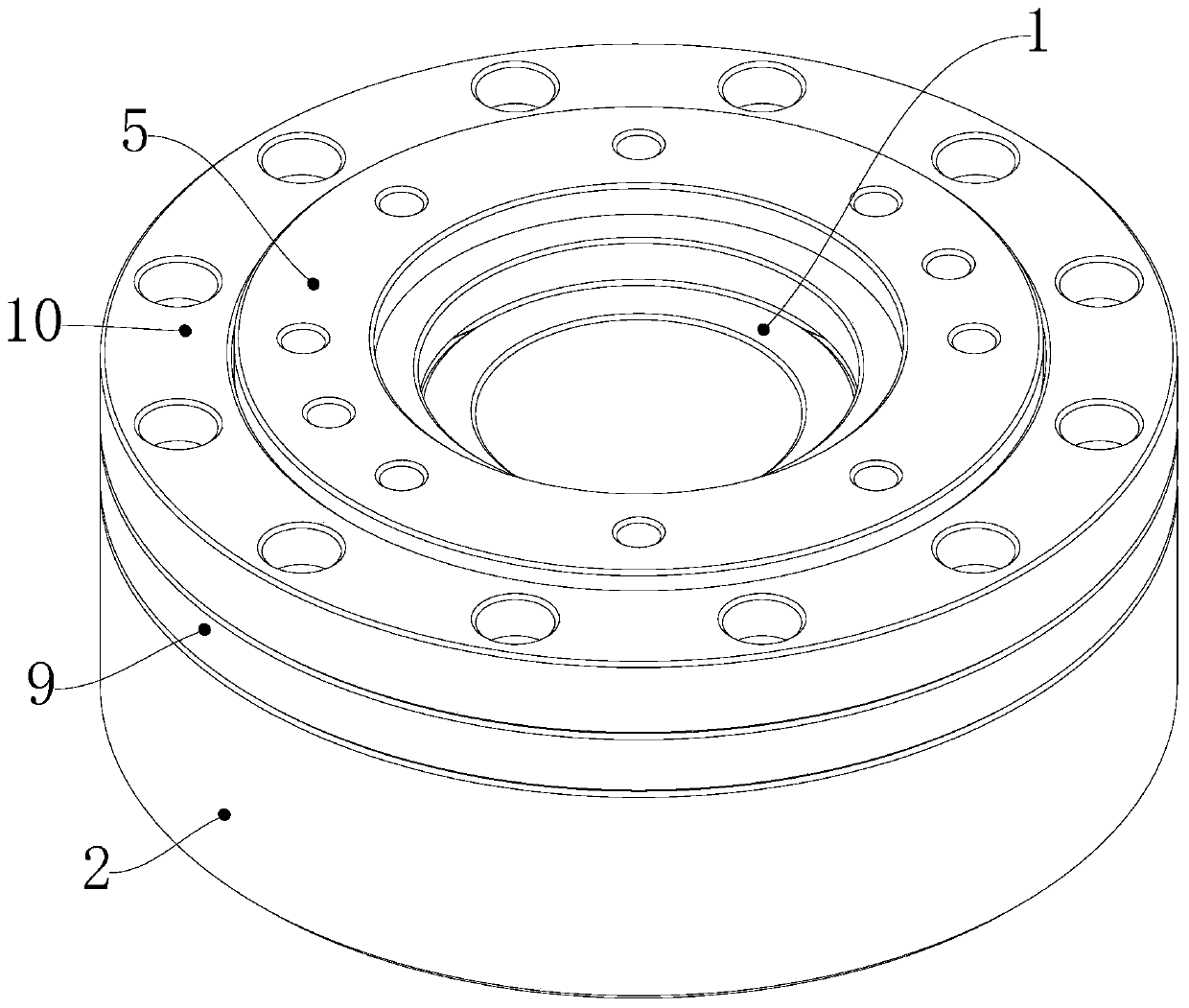

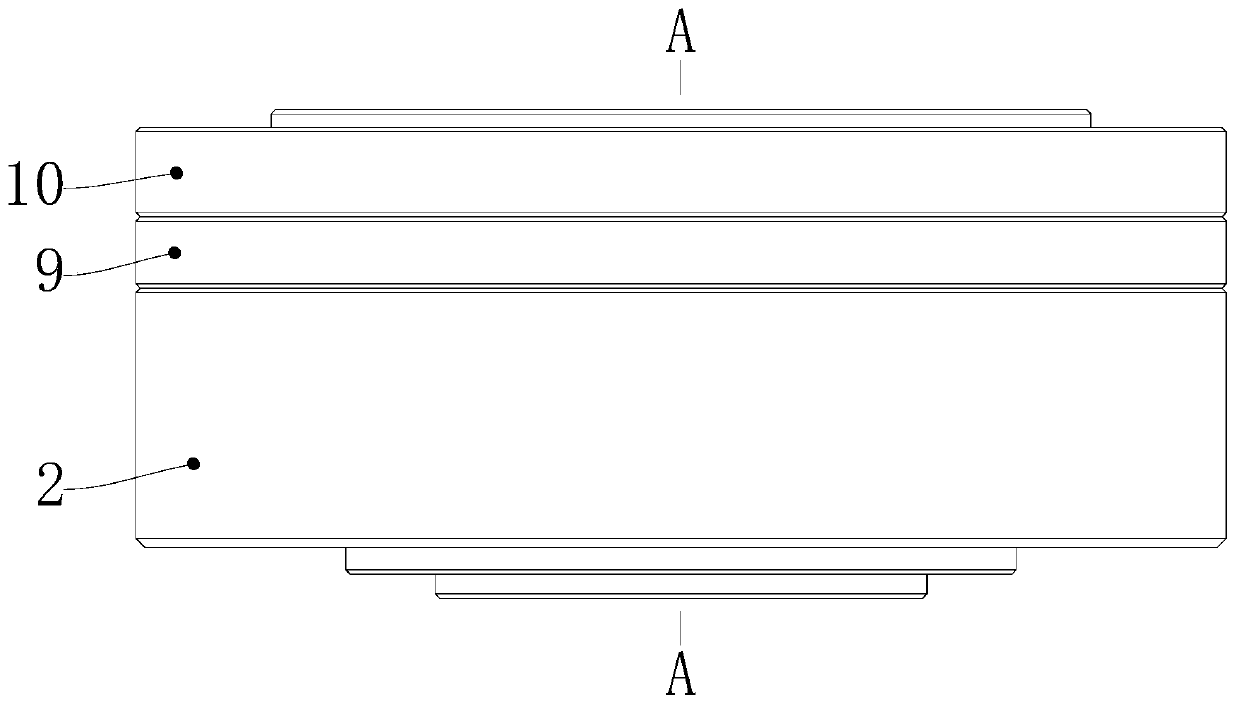

[0028] refer to Figure 1 to Figure 9 As shown, a high-durability single-wave linear reduction bearing in this embodiment includes an input shaft 1, and the input shaft 1 includes a first mounting part 1a, an eccentric part 1b and a second mounting part connected in sequence in the axial direction. Part 1c.

[0029] A first casing 2 is movably sleeved on the periphery of the first installation part 1a, and an end of the first casing 2 close to the eccentric part 1b extends to the periphery of the eccentric part 1b.

[0030] An annular relief groove 2a is formed in the middle of one end of the first housing 2 close to the eccentric part 1b, and a drive disc 3 is movably sleeved on the periphery of the eccentric part 1b, and the drive disc 3 is located on the In the relief groove 2a, the eccentric p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com