Flexible lead, preparation method of flexible electronic device and flexible wireless energy supply device

A technology of flexible wires and wires, which is applied in the field of electronics, can solve the problems of pollution, high price, and long time consumption in the natural environment, and achieve the effect of insensitivity to the external environment and high resource utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] When preparing the two-dimensional flexible wire, the preparation method includes a preparation step and a preparation step.

[0064] In the preparation step, a substrate is provided, which is formed by combining the rigid substrate, the sacrificial layer and the functional film.

[0065] In the preparation step:

[0066] Using femtosecond laser to cut the functional film of the above substrate to realize the patterning of the wires so that the functional film is formed with a planar wire structure;

[0067] Removal of the sacrificial layer so that the planar wire structure is separated from the rigid substrate;

[0068] The planar wire structure is formed as a two-dimensional flexible wire.

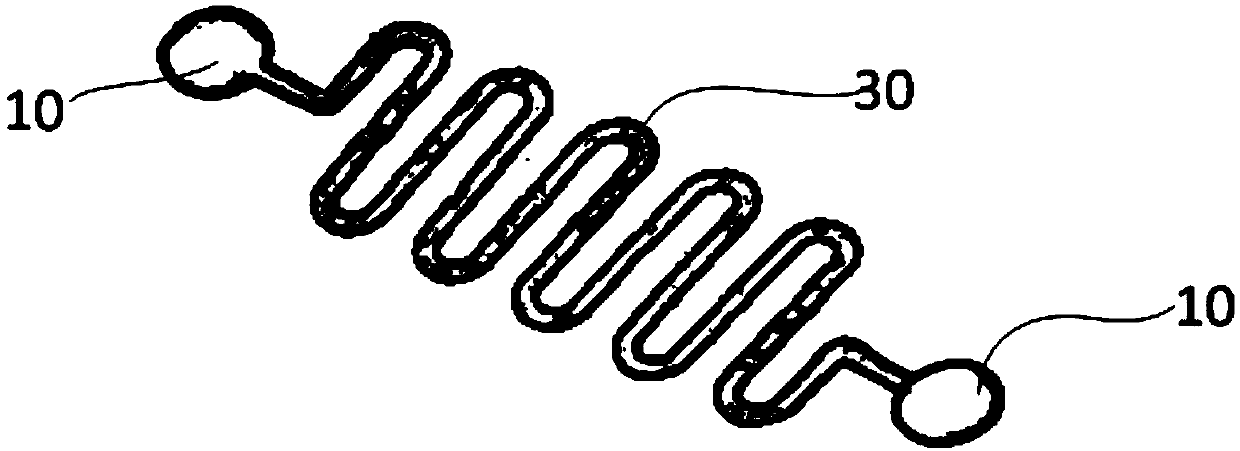

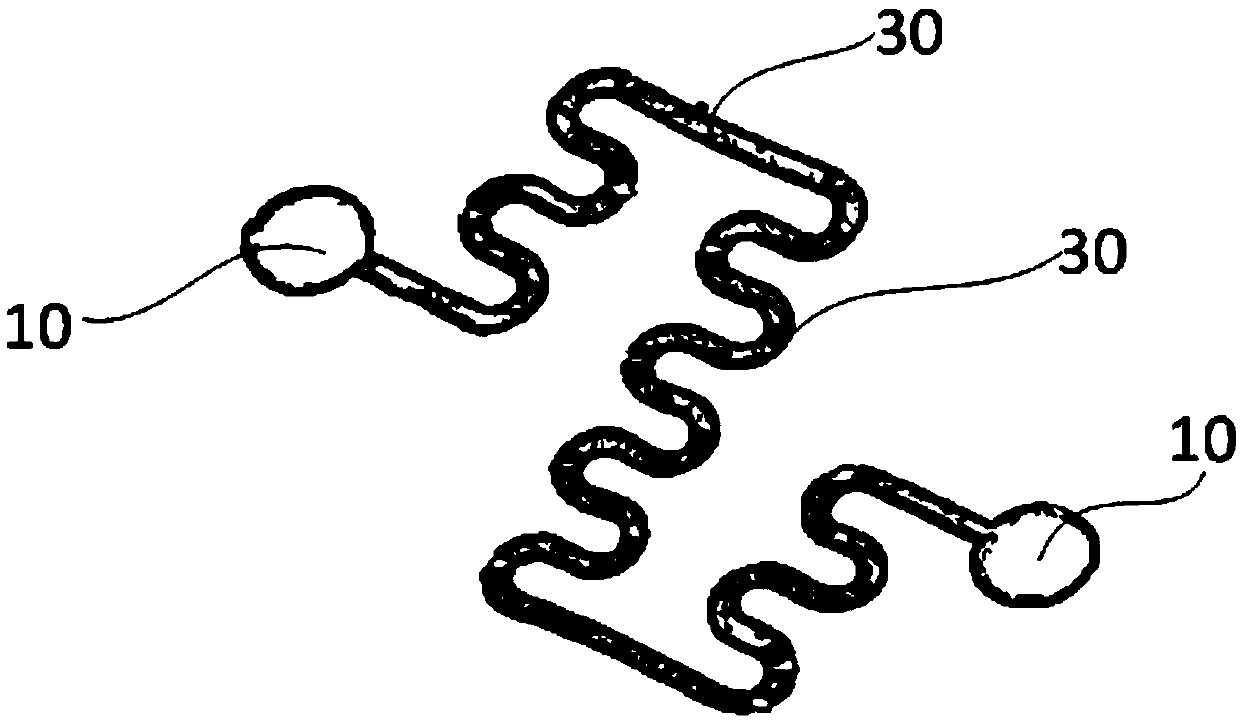

[0069] Such as figure 1 and figure 2 As shown, the planar wire structure of the two-dimensional flexible wire can have fixed regions and non-fixed regions. The fixed area can be fixed to the flexible substrate by sticking, so that the fixed area is formed as the sticking are...

no. 1 example

[0126] In this example, processing such as figure 1 and figure 2 The two types of conductors shown are serpentine conductors and parted serpentine conductors, such as Figure 4 As shown, the composition of the planar wire structure is: a sacrificial layer, a protective layer, a buffer layer, a functional layer and a protective layer arranged in sequence.

[0127] The sacrificial layer is made of polymethyl methacrylate (PMMA); the protective layer is made of PI with a thickness of 3 micrometers; the buffer layer is made of Cr with a thickness of 10 nanometers; the functional layer is made of gold thin film with a thickness of 200 nanometers.

[0128] Prepare a sacrificial layer, a protective layer and a functional film on a rigid substrate by spin coating and coating, and transfer the planar wire structure to a flexible substrate, including the following steps:

[0129] (1) Ultrasonic cleaning of the silicon wafer with acetone, ethanol, and deionized water for 10 min, cycle...

no. 2 example

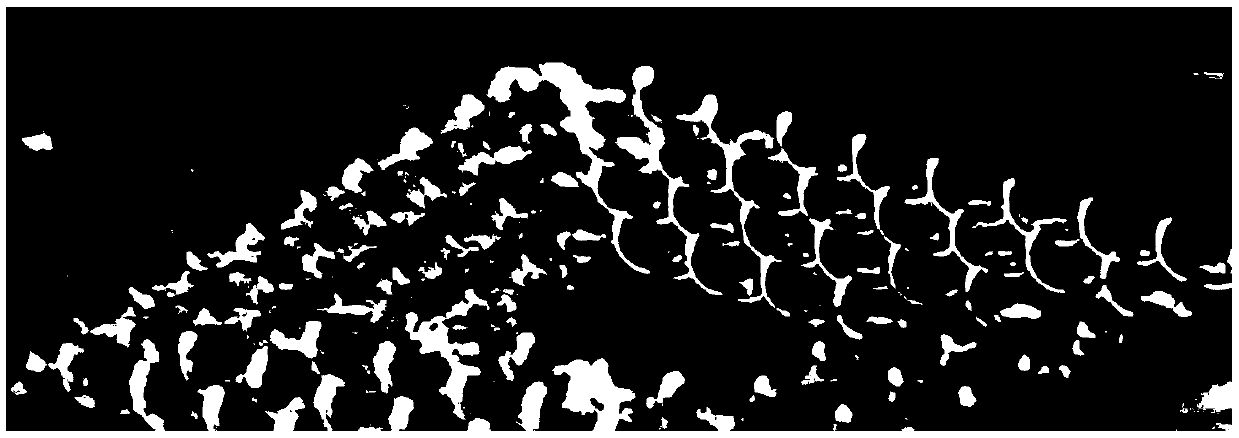

[0141] In this example, prepare as image 3 The helical 3D flexible wire shown and as Figure 5 Circuit shown with flexible wireless power device connected.

[0142] Such as Figure 4 As shown, the composition of the planar wire structure is: a sacrificial layer, a protective layer, a buffer layer, a functional layer and a protective layer arranged in sequence.

[0143] The sacrificial layer is made of PMMA; the protective layer is made of PI with a thickness of 3 microns; the buffer layer is made of Cr with a thickness of 10 nanometers; the functional layer is made of gold thin film with a thickness of 200 nanometers.

[0144] The sacrificial layer, protective layer and functional film are prepared on the rigid substrate by spin coating and coating method, and the planar wire structure is transferred to the pre-stretched flexible substrate, and the preparation of three-dimensional flexible wire is realized by buckling assembly technology. Including the following steps:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com