High-frequency patch resistor and manufacturing method thereof

A chip resistor, high-frequency technology, applied in resistors, trimmer resistors, resistor parts and other directions, can solve the problem of the small resistance adjustment range of high-frequency resistors, the difficulty of technical process control, and the difficulty of technical achievability and other problems, to achieve the effect of reducing cross-sectional area, large resistance adjustment range, and high-efficiency manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

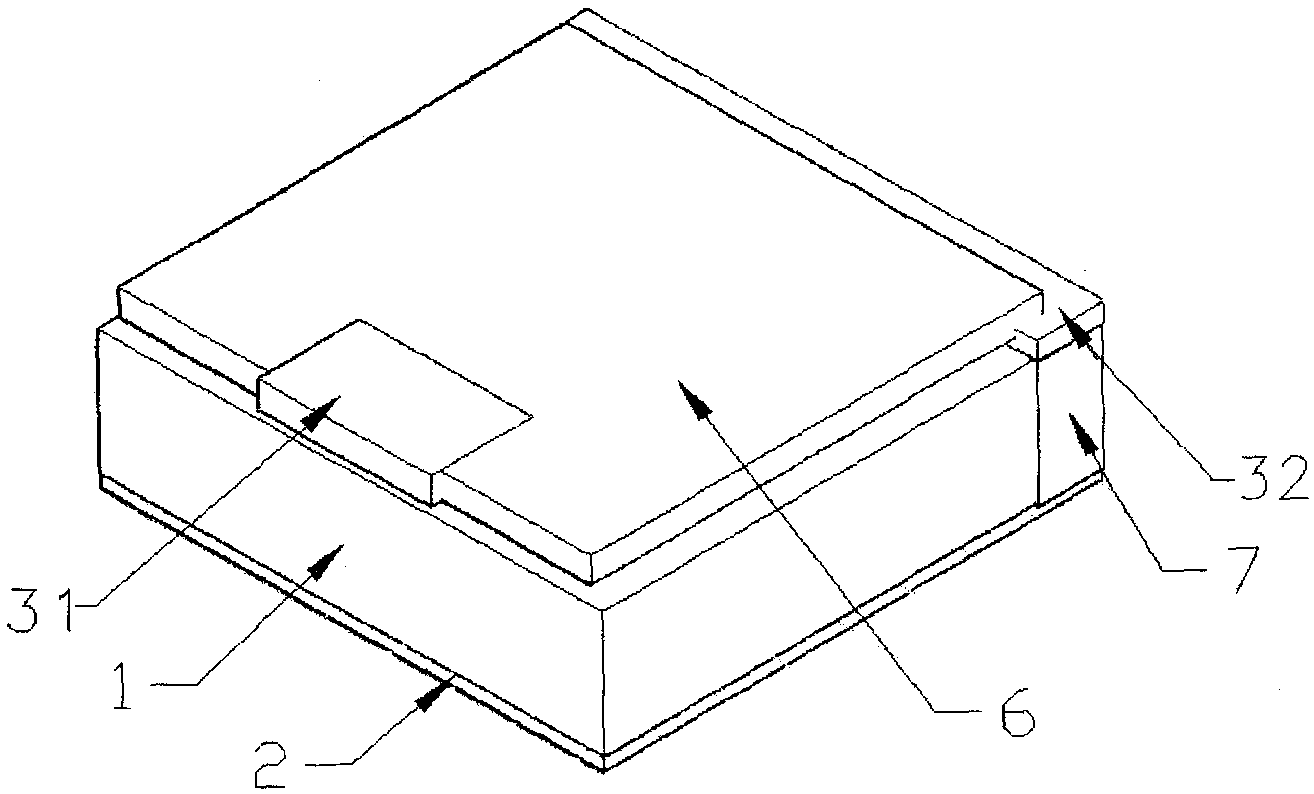

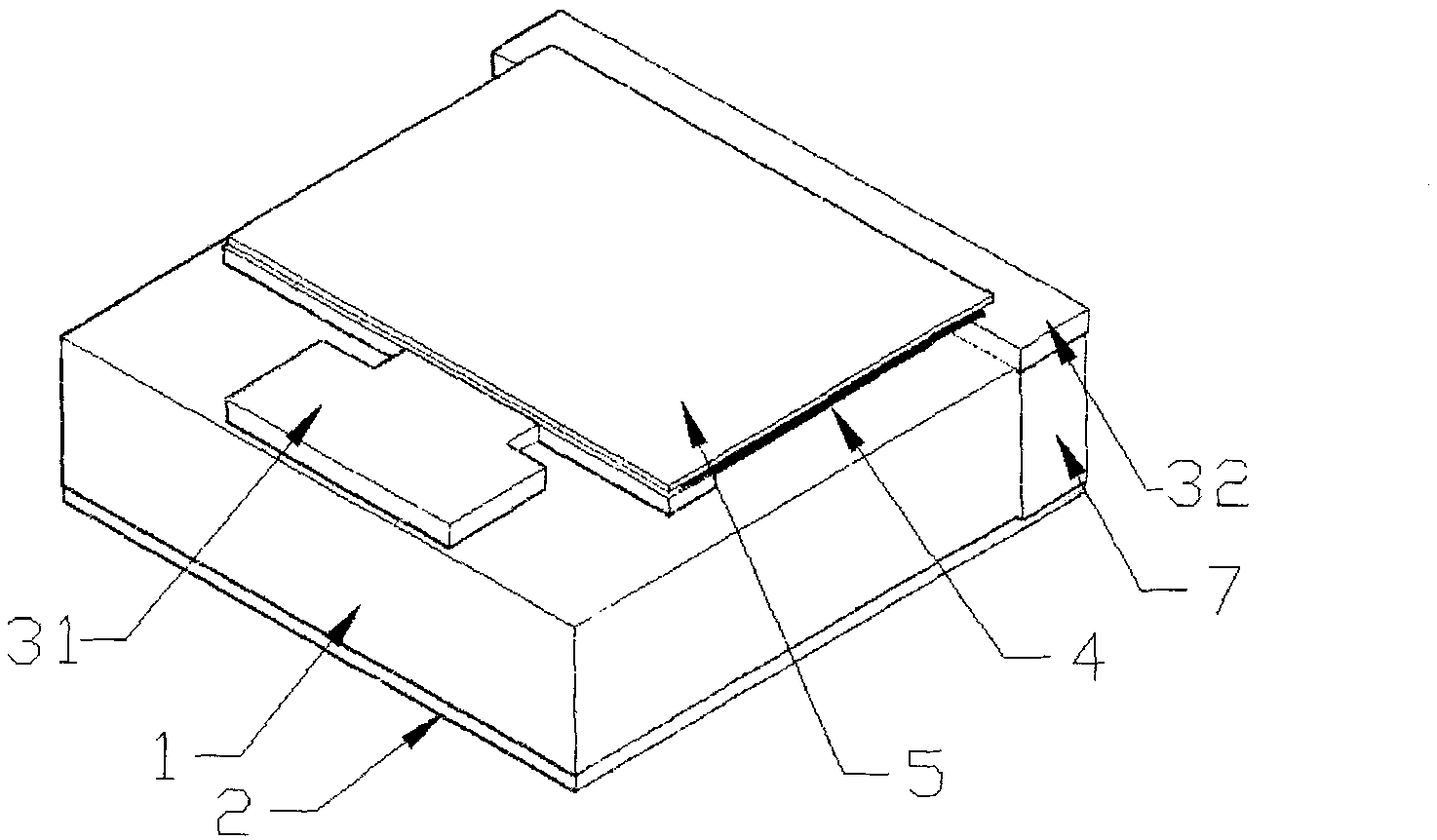

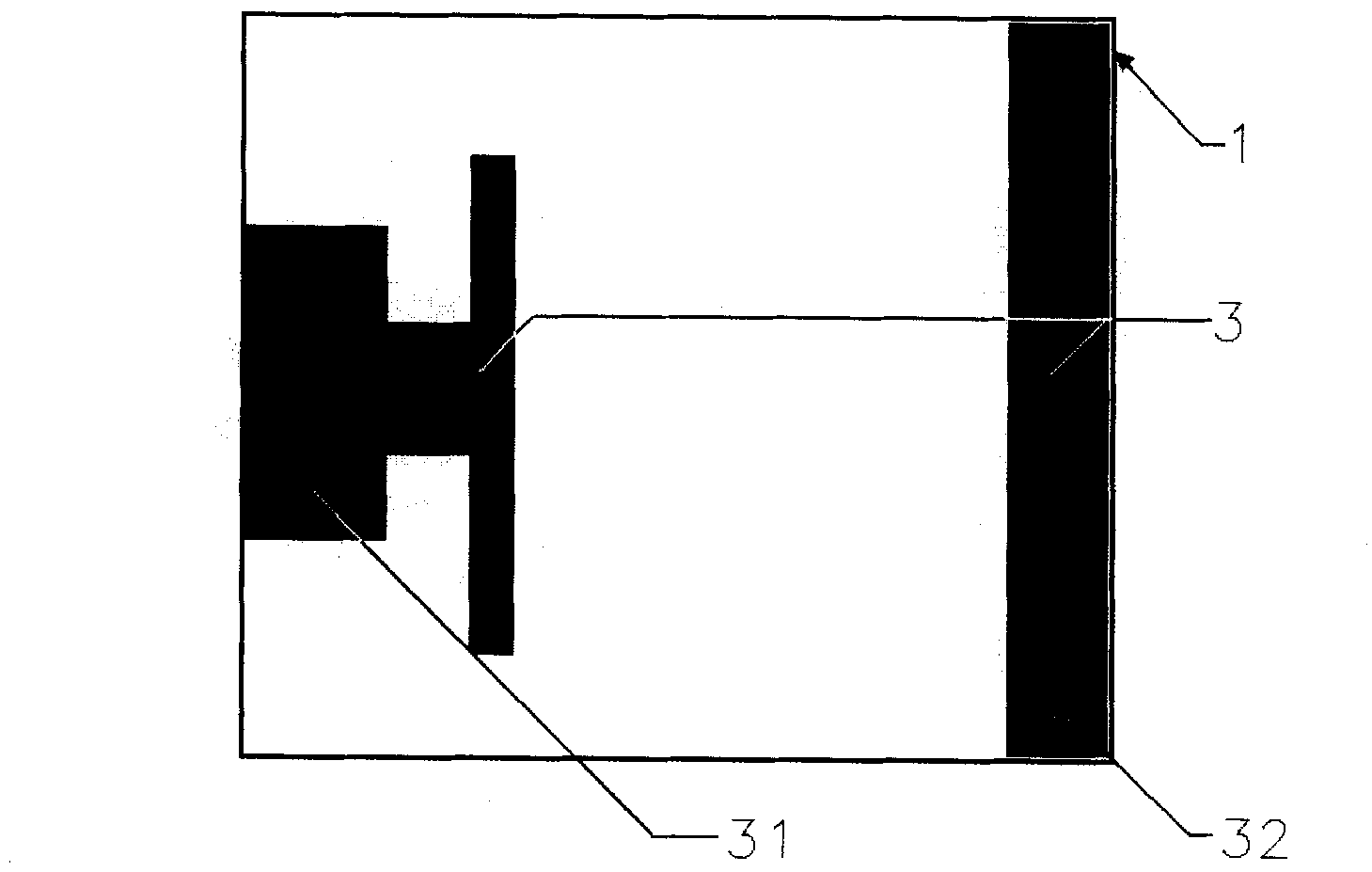

[0042] See eg figure 1 , figure 2 , image 3 , Figure 4 , Figure 9 with Figure 14 As shown, the high-frequency chip resistor provided by the present invention includes a substrate 1 , a back electrode 2 , a surface electrode 3 , a resistor 4 , a protective layer 5 , an outer protective layer 6 and a first side conductive electrode 7 .

[0043] Among them, the substrate 1 is preferably made of aluminum nitride, beryllium oxide or 96-99% alumina ceramics;

[0044] The back electrode 2 is arranged on the lower surface of the substrate 1 , and is preferably printed on the back of the substrate by thick film screen printing, covering at least a part of the lower surface of the substrate 1 . The back electrode 2 provides the function of partially carrying the welding, which increases the reliability of the welding, and also facilitates the adoption of auxiliary heat dissipation measures.

[0045] The surface electrode 3 is arranged on the upper surface of the substrate 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com