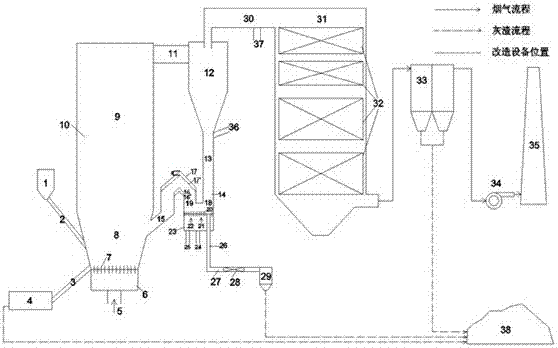

Circulating fluidized bed boiler and material return abnormity adjusting method thereof

A technology of circulating fluidized bed and adjustment method, which is applied in the directions of fluidized bed combustion equipment, combustion method, and fuel burned in a molten state, can solve the problems of abnormal material return, difficulty in material return, poor fluidization, etc. The effect of stable pressure, normal fluidization, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A remodeled 50MW circulating fluidized bed boiler, after the boiler was put into operation, the abnormal phenomenon of material return was serious, and boiler fire and non-shutdown accidents occurred frequently. Afterwards, the adjustment method one in this patent was adopted, and the return valve was technically transformed, that is, the height position of the rising section of the return valve was moved down by 300mm, and the position of the top cap of the return was also moved down by 300mm. The height position of the rising section of the return valve is lowered by 300mm, which reduces the resistance of the return material. The circulating ash can continuously enter the dense phase area of the furnace. The effect is obvious.

Embodiment 2

[0069] A newly built 135MW class circulating fluidized bed boiler, the loose air of the boiler has repeatedly flowed back during operation, causing abnormal material return, and then the adjustment method 2 was adopted, that is, the upper part of the return vertical pipe at the lower part of the cyclone separator was set. Material sealing air duct, using this device plays a role in sealing the circulating ash in the standpipe, which solves the problem of loose wind backflow at the lower part of the feeder, and effectively solves the problem of abnormal material return caused by loose wind backflow, and the use effect is obvious.

Embodiment 3

[0071] A newly built 300MW class circulating fluidized bed boiler, during the operation of the boiler, there were many ash accumulations in the horizontal flue of the boiler outlet. The return material is abnormal, and the third adjustment method is adopted, that is, set up a purge device in the horizontal flue, and turn on the device regularly during operation to blow away the ash in the horizontal flue in time, effectively solving the problem of excessive ash accumulation in the horizontal flue. The ash causes the sudden rise of the material level in the standpipe and causes the problem of abnormal material return, so as to ensure the safe operation of the boiler and the use effect is obvious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com