Method for forecasting splashing in argon oxygen refined low-carbon ferrochromium production process

A low-carbon ferrochrome production process technology, applied in the field of spatter prediction in the production process of argon-oxygen refining low-carbon ferrochrome, can solve problems such as difficult pressure spraying effect, large interference, difficult engineering application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

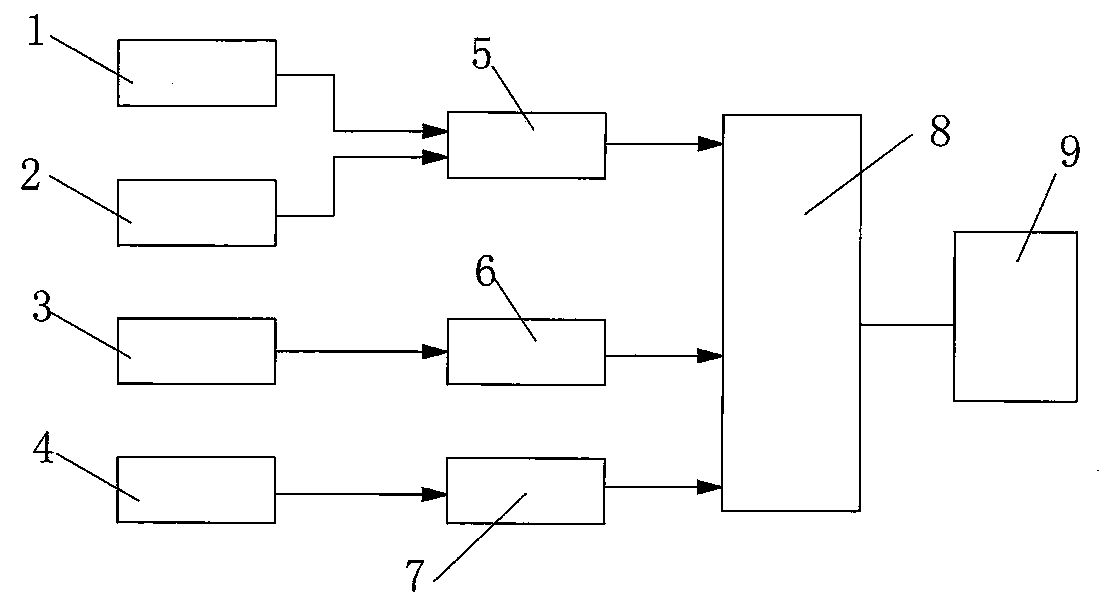

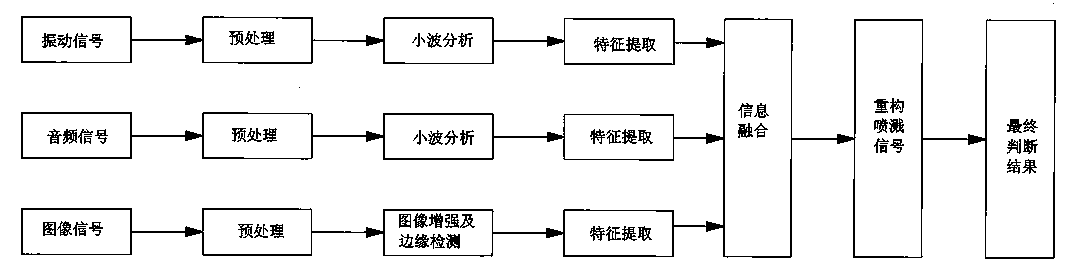

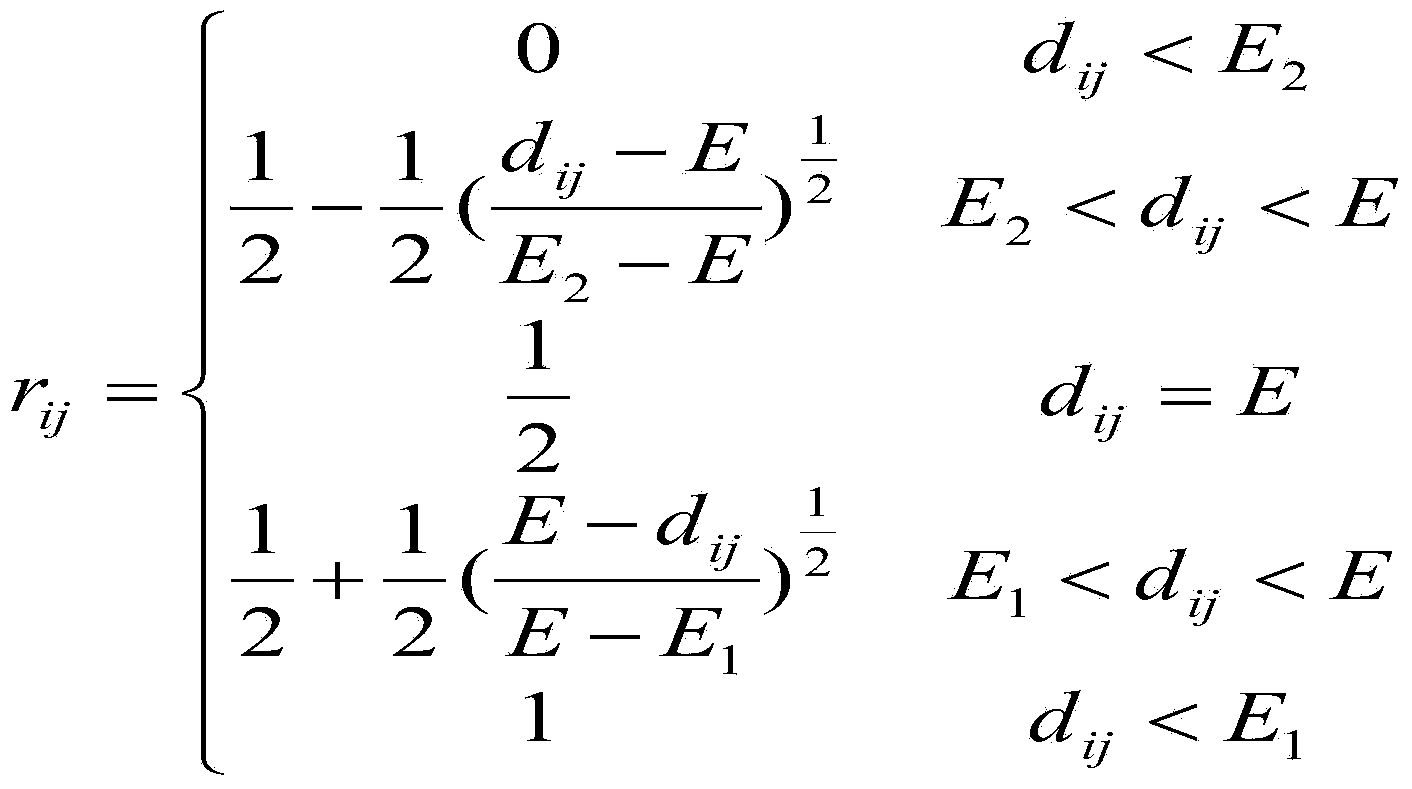

[0056] The method of the present invention comprises the following steps: Please refer to figure 1 with figure 2 as shown,

[0057] 1. Collection of information:

[0058] The first vibration sensor 1, the second vibration sensor 2, the super-pointing microphone 3, and the infrared camera 4 are respectively used to collect vibration signals, audio signals, and flame image signals related to splashing in the production process of argon-oxygen refining low-carbon ferrochrome; The first vibration sensor 1 is installed on the high-pressure cooling water inlet pipeline of the AOD furnace to measure the vibration signal caused by splashing, and the second vibration sensor 2 is installed on the gas supply pipeline of the AOD furnace to analyze and eliminate the vibration interference caused by the gas supply pipeline. After the second signal processing box 5 processes, it is transmitted to the multi-function acquisition card 8; the audio signal in the furnace is collected by the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com