Method for automatically controlling convexity and/or wedge of hot rolled in series type rolling machine and system thereof

An automatic control system, series technology, applied in the direction of profile control, etc., can solve the problems that cannot be improved, the crown and shape control process and equipment cannot meet the quality requirements of strip steel plate shape, and the crown control method is single.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0106] A preferred embodiment of the present invention is described below to illustrate the content of the present invention, but this embodiment is not intended to limit the present invention in any form.

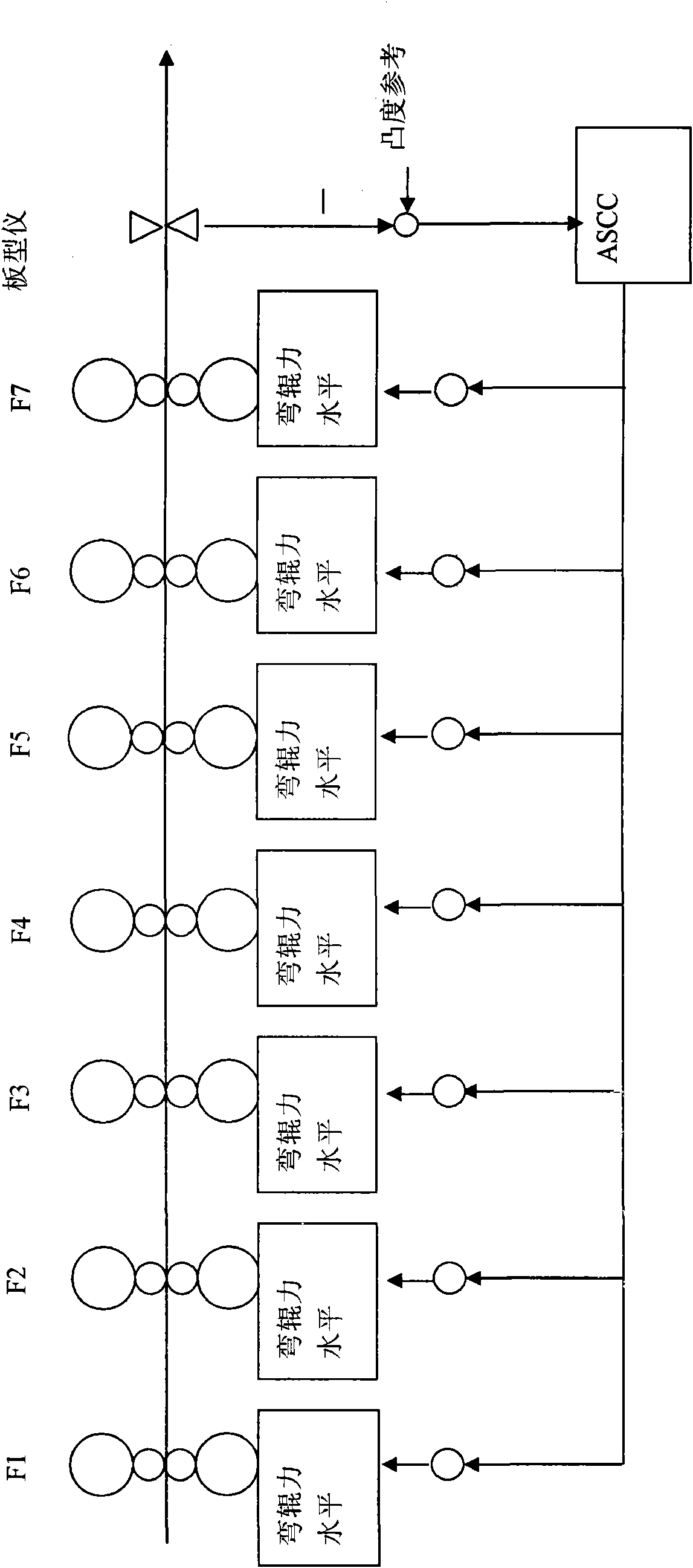

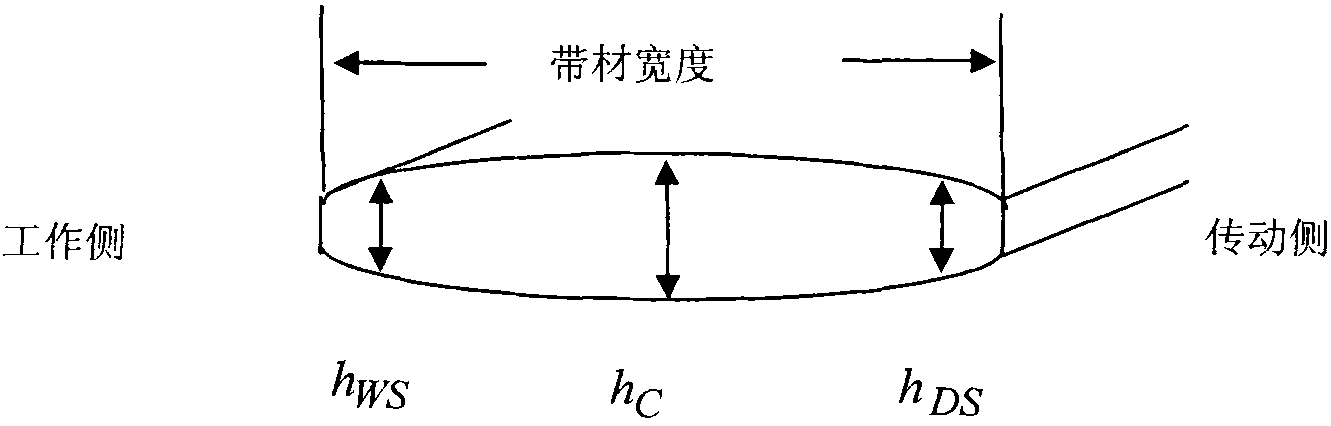

[0107] Such as figure 1 As shown, the present embodiment relates to a 7-stand (F1 to F7) tandem strip steel production line finishing mill, a flatness meter is arranged at the exit of the finishing rolling, and the flatness meter and ASCC (which can be a programmable logic controller) PLC) connection, at the same time, the ASCC is also connected with the work roll bending adjustment system and the roll gap adjustment system in each finishing stand.

[0108] The ASCC stop and start process is as follows: when the head of the strip reaches the shape meter at the exit of the finishing mill, the ASCC starts to work, and when the tail of the strip is cut by the flying shear, the ASCC stops working.

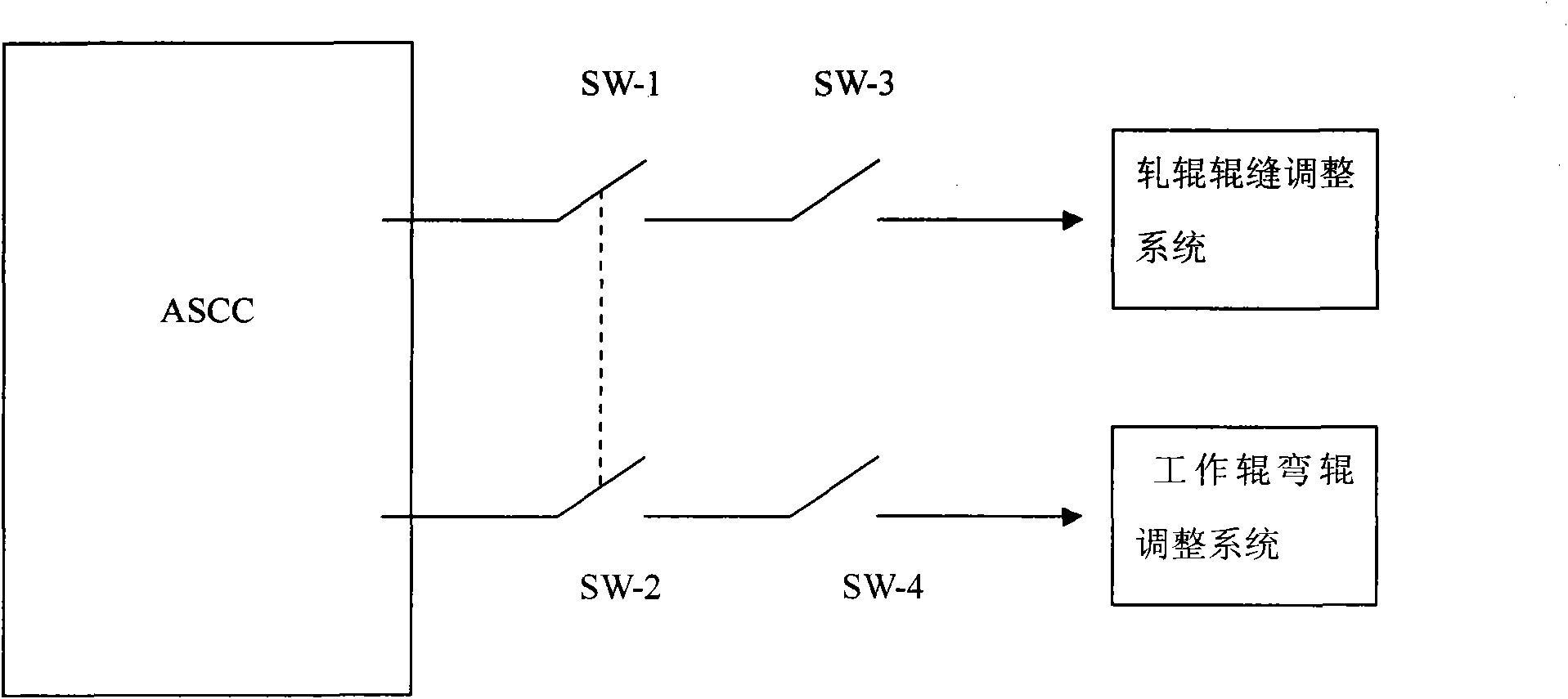

[0109]The output of this ASCC has two types: one is the roll gap leveling val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com